Efficient sectioning machine for lily bulbs

A technology of splitting machine and bulb, applied in the field of high-efficiency lily bulb splitting machine, can solve the problems of high labor intensity, loss of surface juice, damage to lily scales, etc., and achieve the effect of ensuring smoothness and uniform speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

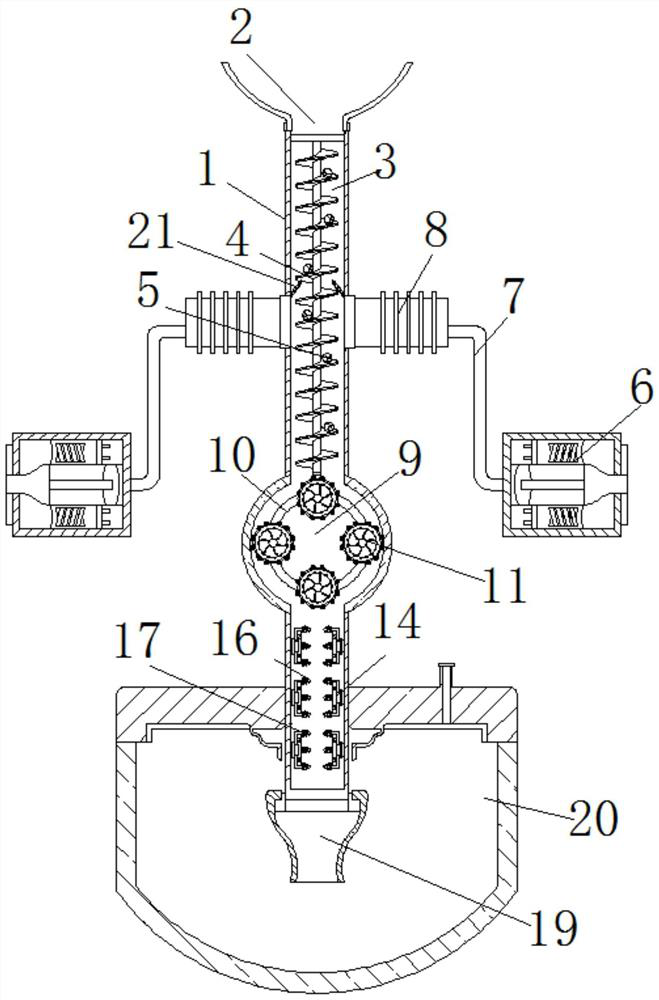

[0025] see figure 1 , a high-efficiency lily bulb splitter, comprising a device main body 1, the top of the device main body 1 is provided with a feed port 2, the feed port 2 is bowl-shaped, and the bottom of the feed port 2 is connected to There is a feeding channel 3, and the inside of the feeding channel 3 is provided with a screw feeder 4, and the screw feeder 4 is spirally encircling, and a lily bulb main body 5 is placed on the surface of the screw feeder 4, The feeding port 2 is used for feeding the main body 5 of the lily bulb.

[0026] By adding the lily bulb main body 5 into the interior of the device main body 1 through the feed port 2, the lily bulb main body 5 first passes through the screw feeder 4, and is screwed under the guidance of the screw feeder 4 to avoid a large number of lily bulb main bodies 5 enter the main body 1 of the device at the same time to cause blockage, so as to ensure the smoothness of the transportation of the lily bulb main body 5 and to...

Embodiment 2

[0028] see Figure 2-3 , a high-efficiency lily bulb splitter, comprising a device main body 1, the top of the device main body 1 is provided with a feed port 2, the feed port 2 is bowl-shaped, and the bottom of the feed port 2 is connected to There is a feeding channel 3, and the inside of the feeding channel 3 is provided with a screw feeder 4, and the screw feeder 4 is spirally encircling, and a lily bulb main body 5 is placed on the surface of the screw feeder 4, The feeding port 2 is used for feeding the main body 5 of the lily bulb.

[0029] The device main body 1 also includes a wind body maker 6, the wind body maker 6 can generate a wind body, the outside of the wind body maker 6 is connected with a wind body pipeline 7, and one end of the wind body pipeline 7 It is connected to the wind generator 6, and the other end is connected to a pressurization valve 8, which is connected to the feed channel 3, and the pressurization valve 8 can increase the impact force of the ...

Embodiment 3

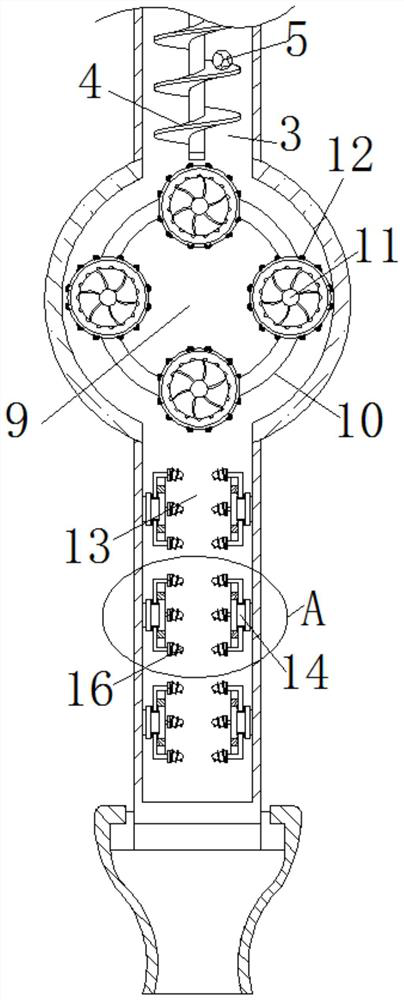

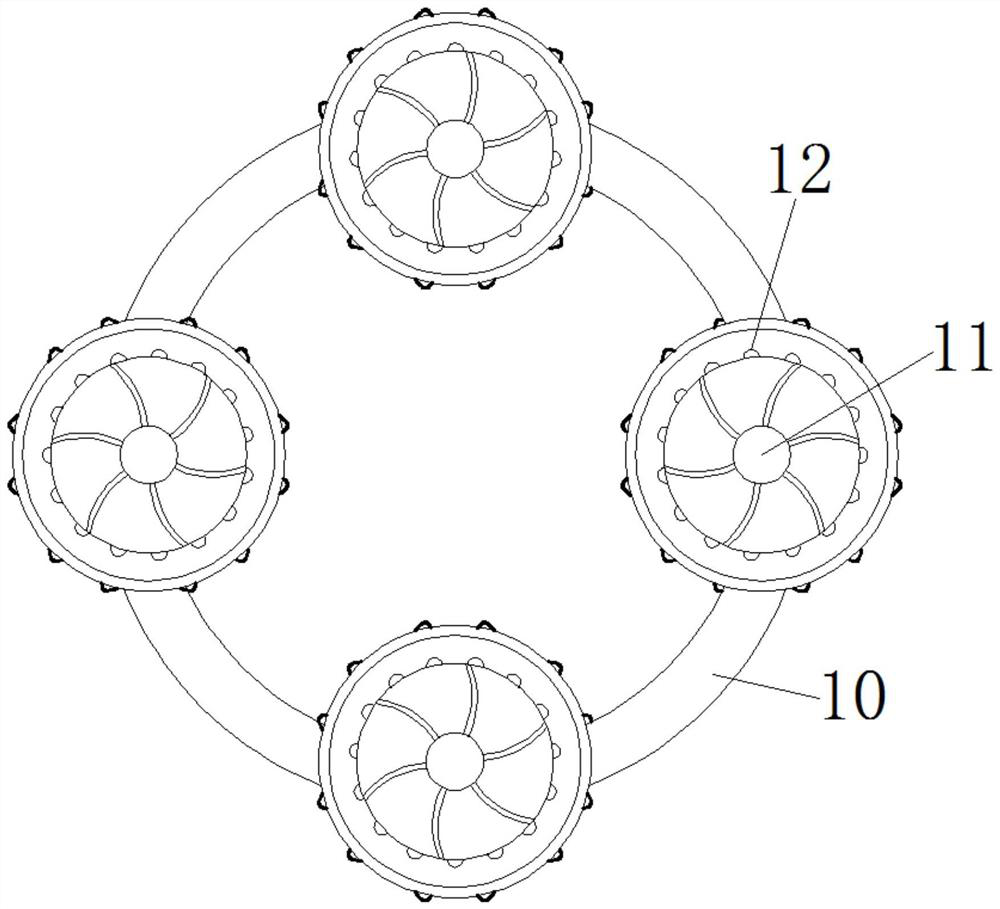

[0032] see Figure 4-6 , a high-efficiency lily bulb splitter, comprising a device main body 1, the top of the device main body 1 is provided with a feed port 2, the feed port 2 is bowl-shaped, and the bottom of the feed port 2 is connected to There is a feeding channel 3, and the inside of the feeding channel 3 is provided with a screw feeder 4, and the screw feeder 4 is spirally encircling, and a lily bulb main body 5 is placed on the surface of the screw feeder 4, The feed port 2 is used for the feeding of the lily bulb main body 5, the feed channel 3 is a cylindrical long pipe, the center position of the feed channel 3 is provided with a split channel 9, and the split channel The inside of 9 also includes a connecting shaft 10, the connecting shaft 10 is crescent-shaped, the outer side of the connecting shaft 10 is connected with a split ball 11, and the outer side of the split ball 11 is provided with a split block 12, the split The petals 12 are raised hemispheres, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com