A garlic processing device integrating peeling, slicing and crushing garlic

A processing device and garlic paste technology, which are applied to peeling utensils, household machinery for filtering food, household utensils, etc., to achieve the effects of small size, reduced product accumulation and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with drawings and embodiments.

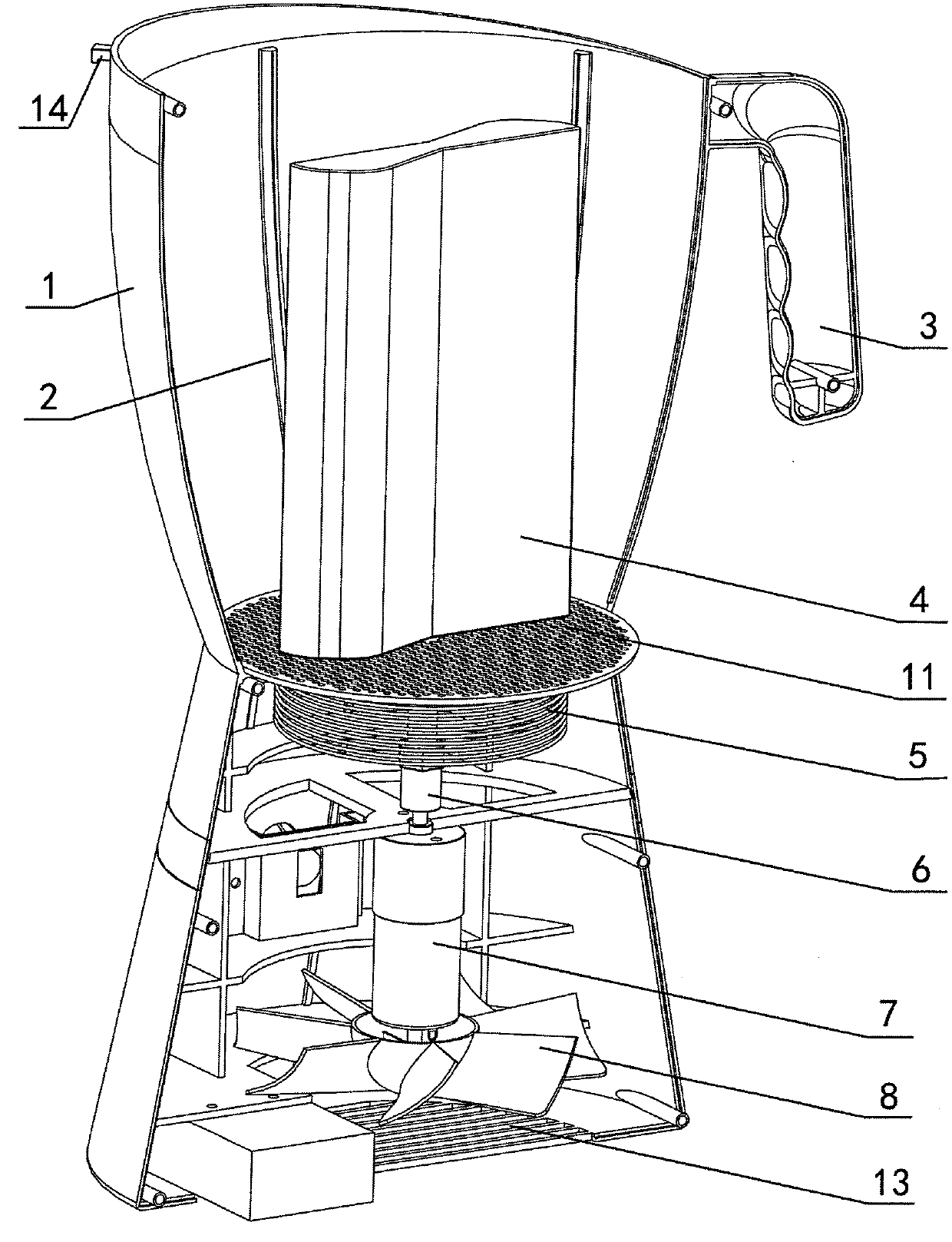

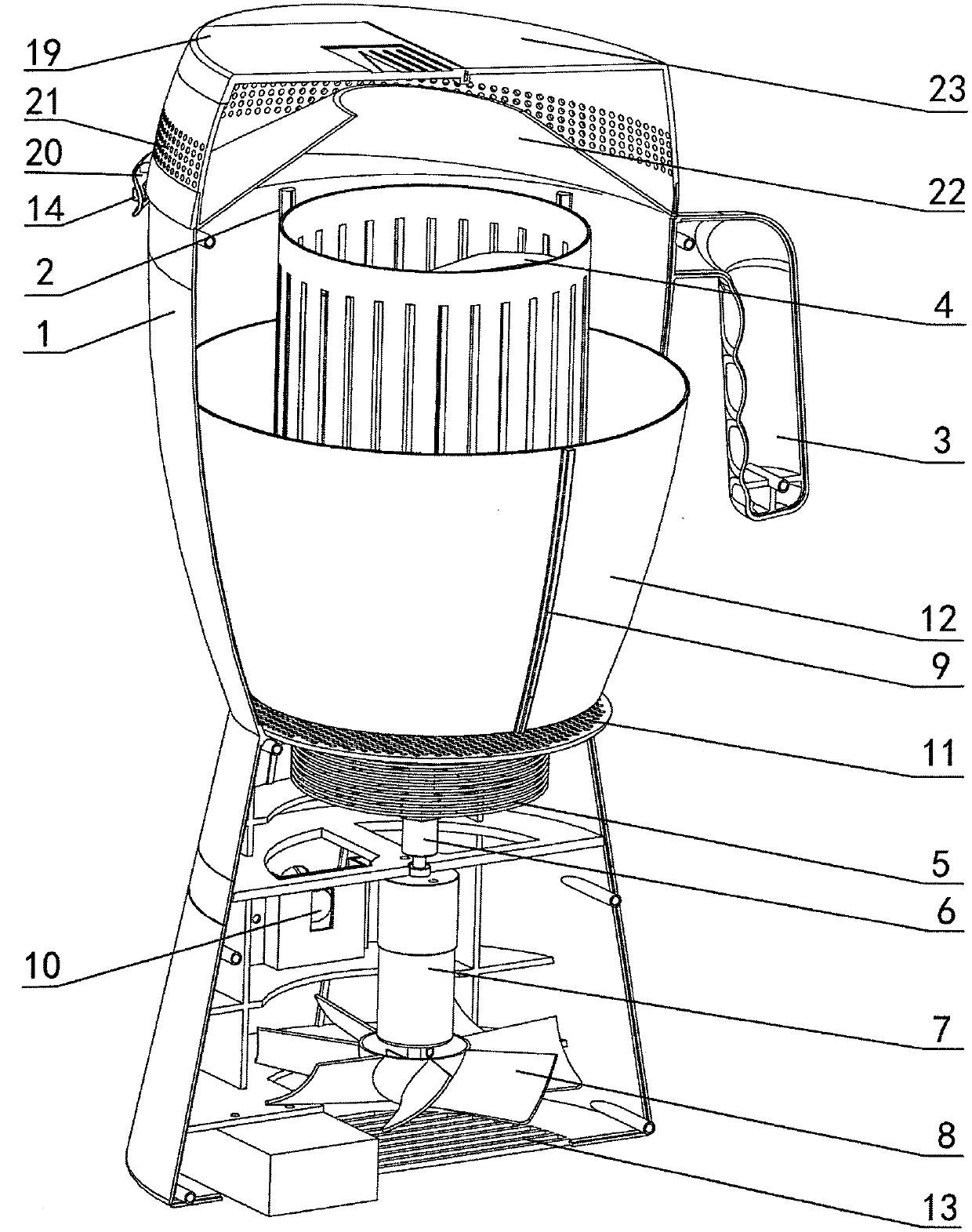

[0029] Such as figure 1 As shown, the present invention is mainly composed of housing 1, friction edge 2, handle 3, rotating rod 4, heating resistance wire 5, coupling 6, motor 7, fan blade 8 and the like.

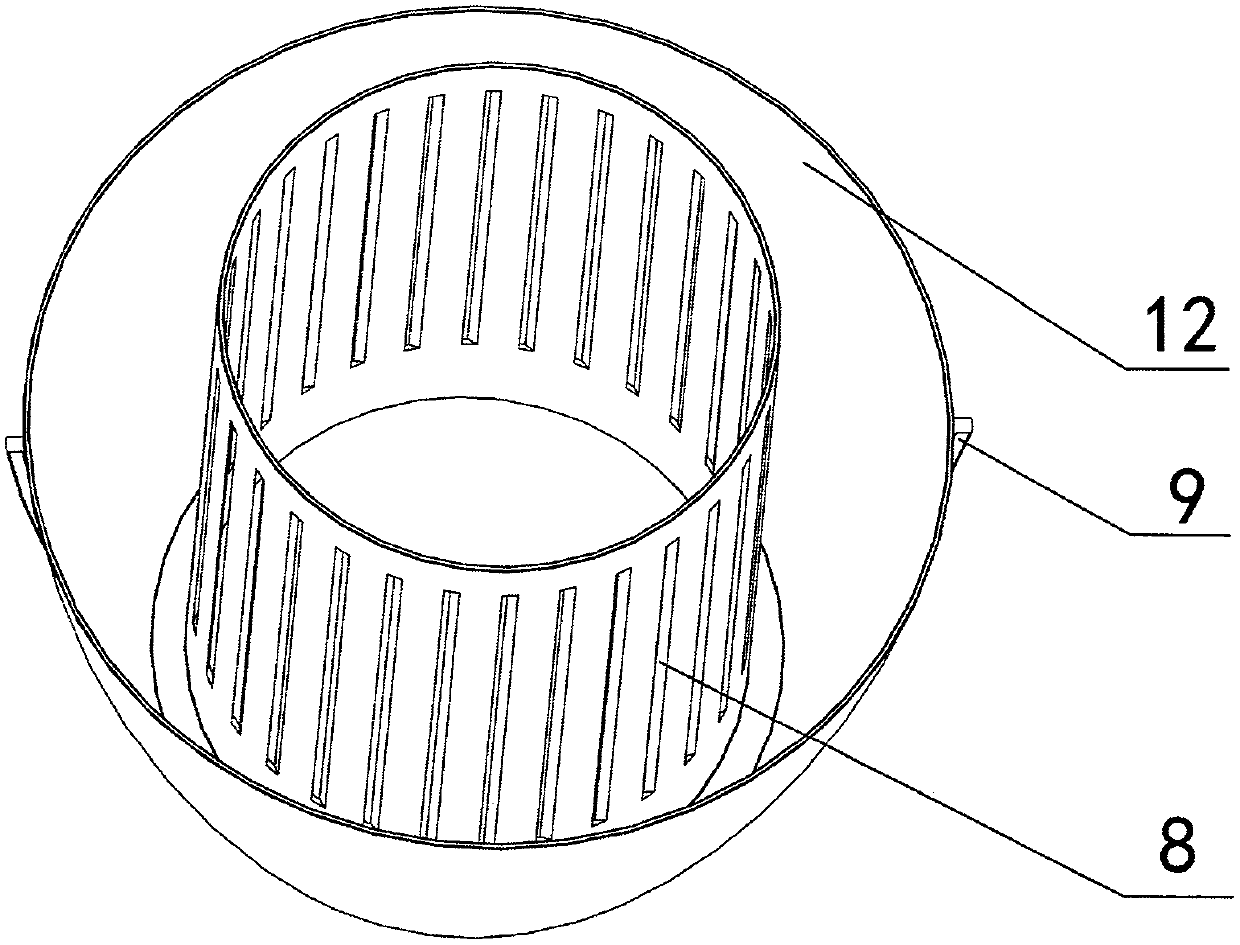

[0030] Garlic peeling parts are mainly made up of rotating rod 4, heating resistance wire 5, shaft coupling 6, motor 7, and fan blade 8. The fan blade 8 is connected to one end of the motor 7 , the rotating rod 4 is connected to the other end of the motor 7 through a coupling 6 , and the heating resistance wire 5 is placed between the fan blade 8 and the rotating rod 4 . The motor 7 drives the fan blade 8 and the rotating rod 4 to rotate. The wind blown by the fan blade 8 passes through the heating resistance wire 5 to form hot air and blows to the surrounding of the rotating rod 4. Water blasting; under the interaction between the rotating rod 4 and the friction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com