Double-layer isolating negative-pressure dust-proof system

A negative pressure and dust-proof technology, which is applied in the field of double-layer isolation negative pressure dust-proof system, can solve problems such as waste of human resources, internal pollution, and dust in the production workshop, so as to achieve high efficiency in dust prevention and dust removal, and ensure cleanliness and cleanliness. cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

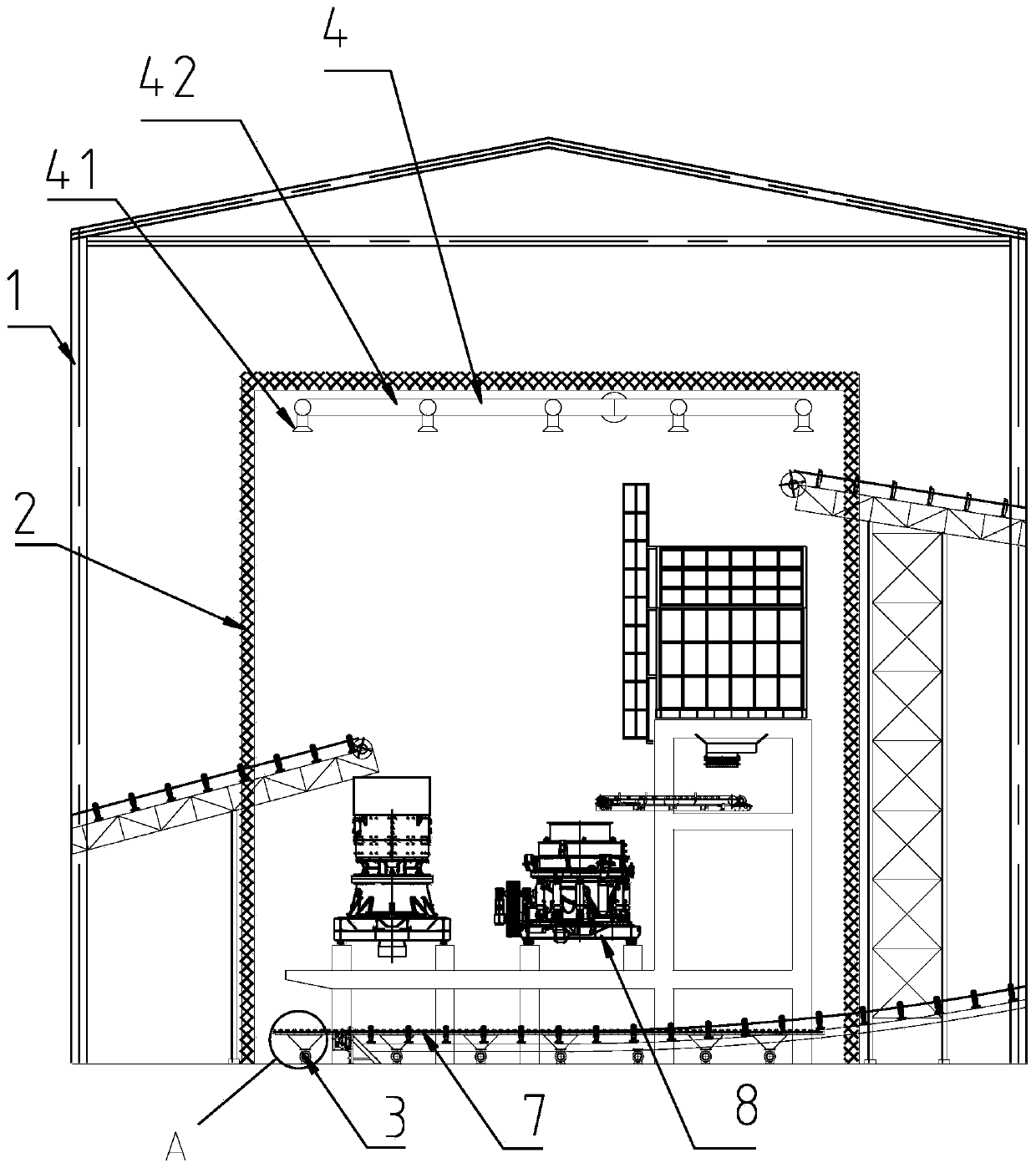

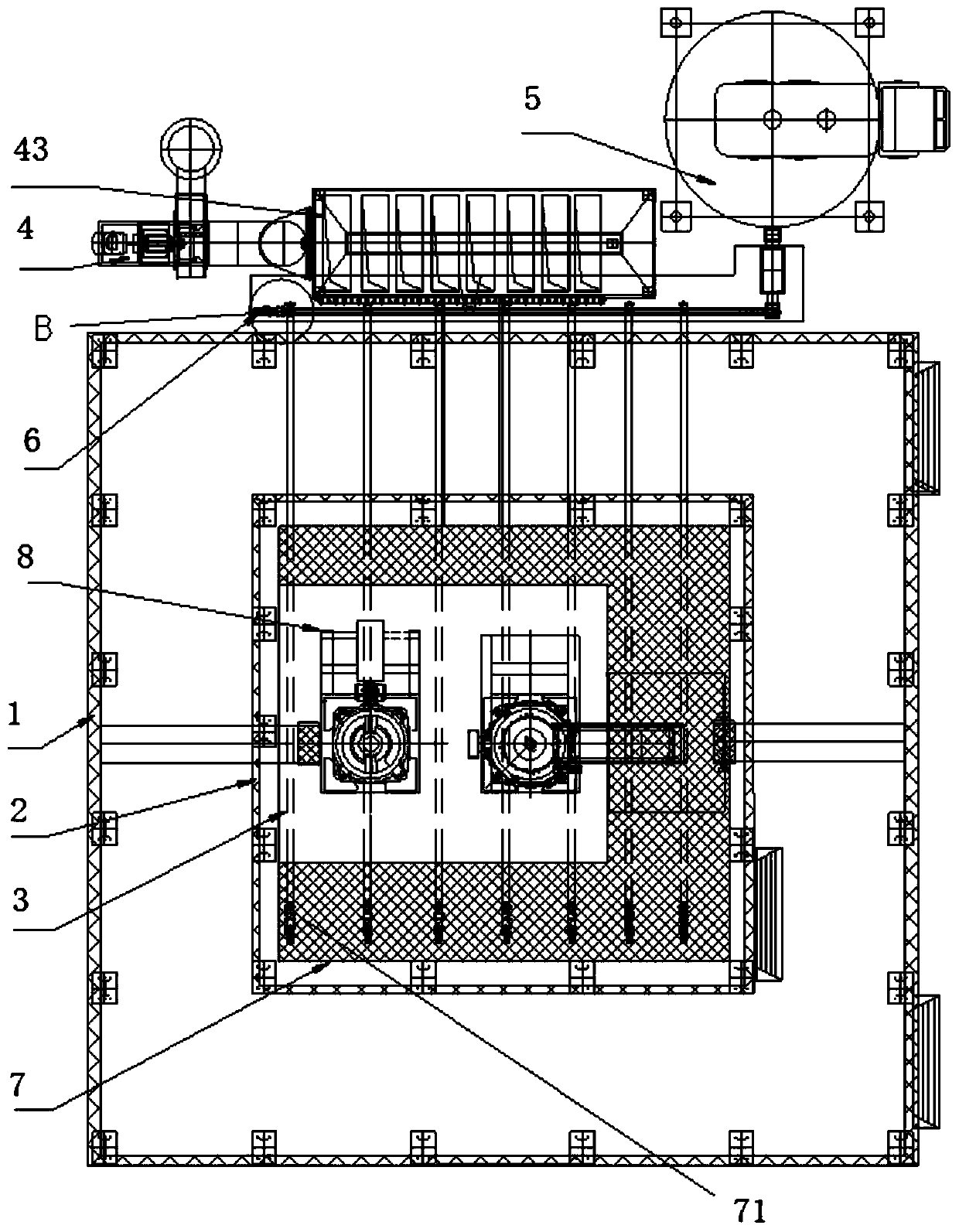

[0034] In one embodiment of the present invention, as Figure 1-6 As shown, a double-layer isolation negative pressure dustproof system is provided, an outer sealing cover 1 and an inner sealing cover 2, and the inner sealing cover 2 is located inside the outer sealing cover 1;

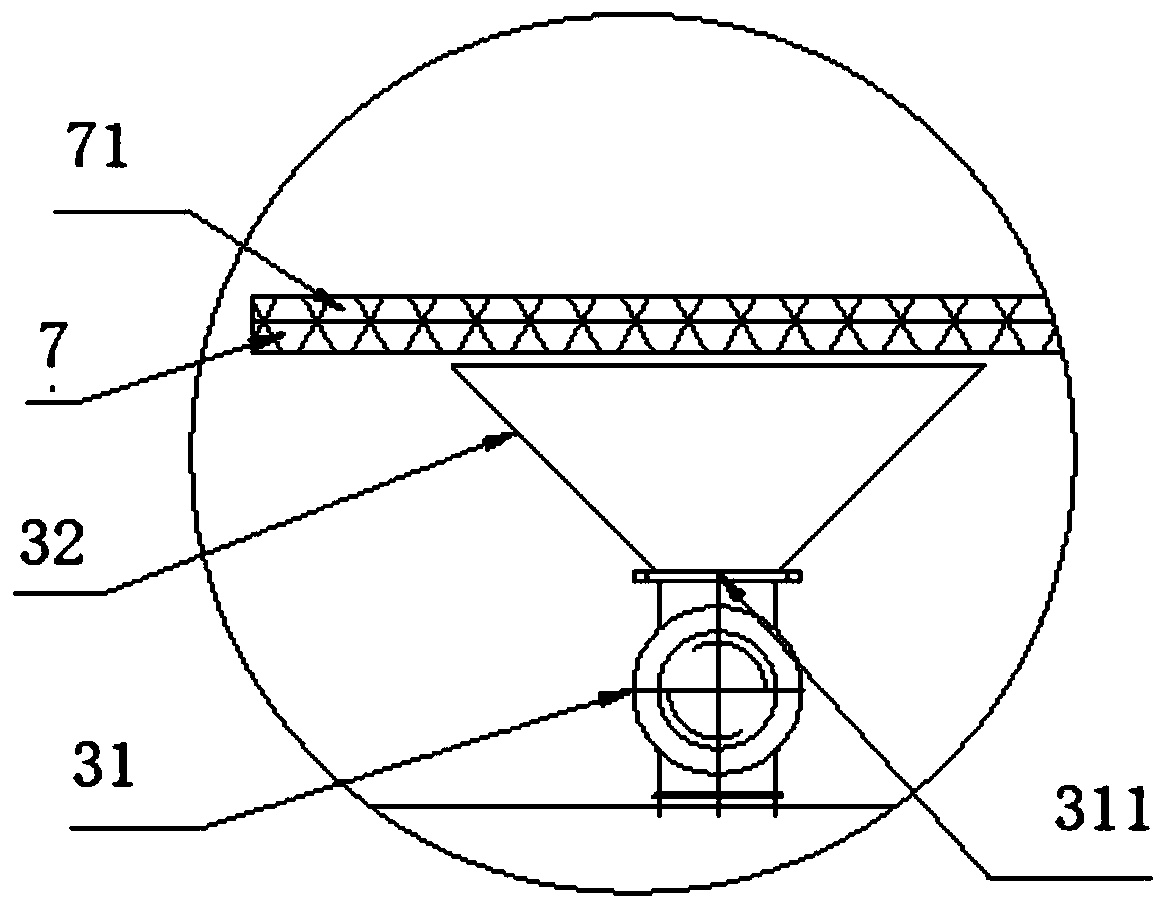

[0035] A dust collecting device 3, the dust collecting device 3 is connected to the bottom of the inner sealing cover 2, and is used to collect dust falling on the bottom surface of the inner sealing cover 2;

[0036] A dust collecting device 4, the dust collecting device 4 is connected to the top of the inner sealing cover 2, and is used for drawing air and filtering the dust in the dust-containing gas in the inner sealing cover 2;

[0037] A s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com