Viscose type textile cloth dust removing device

A textile cloth and dust removal device technology, applied in the textile field, can solve the problems of polluting the air environment, high energy consumption of dust removal devices, and affecting the quality of textile cloth products, so as to avoid secondary pollution and reduce energy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

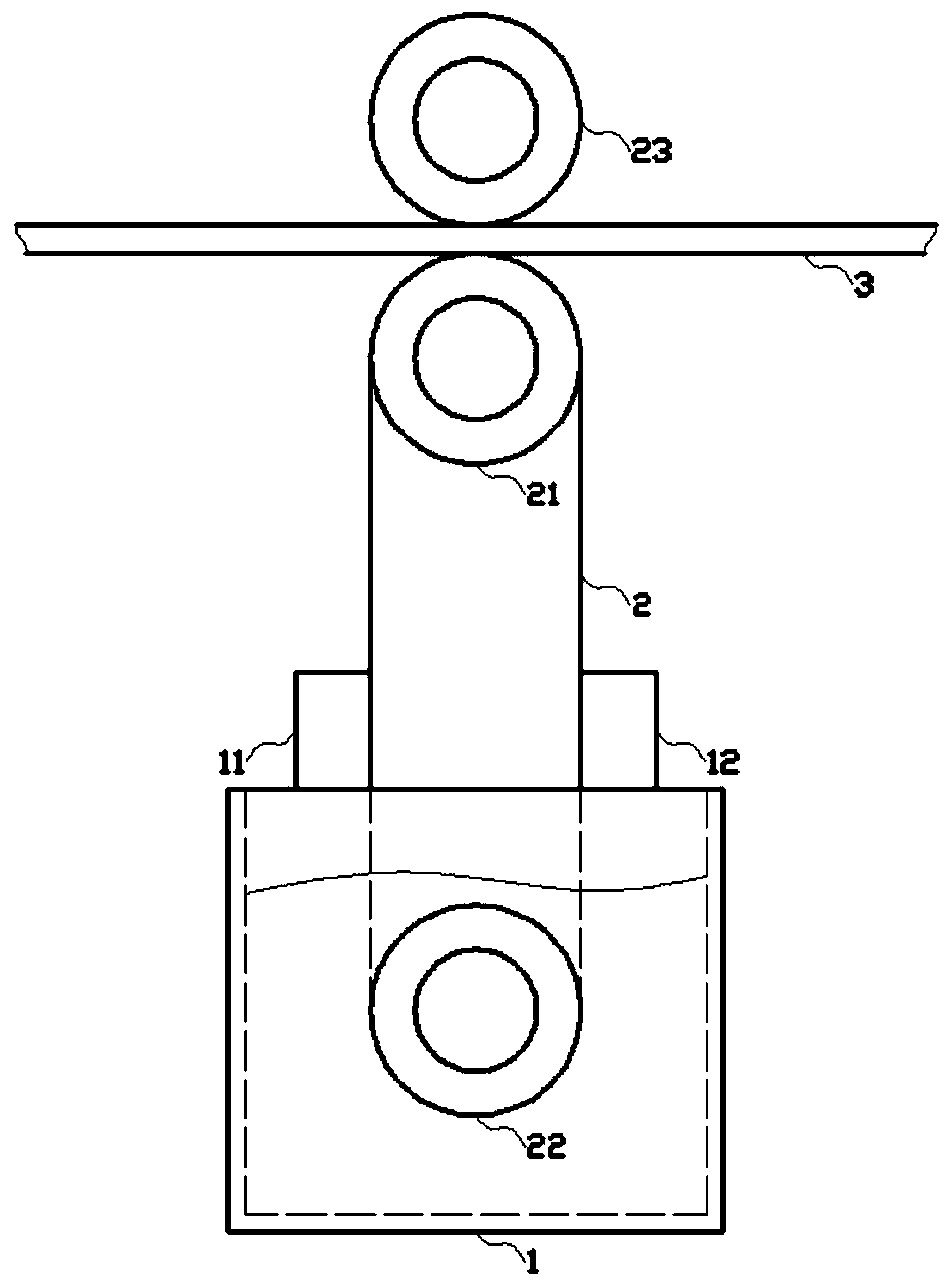

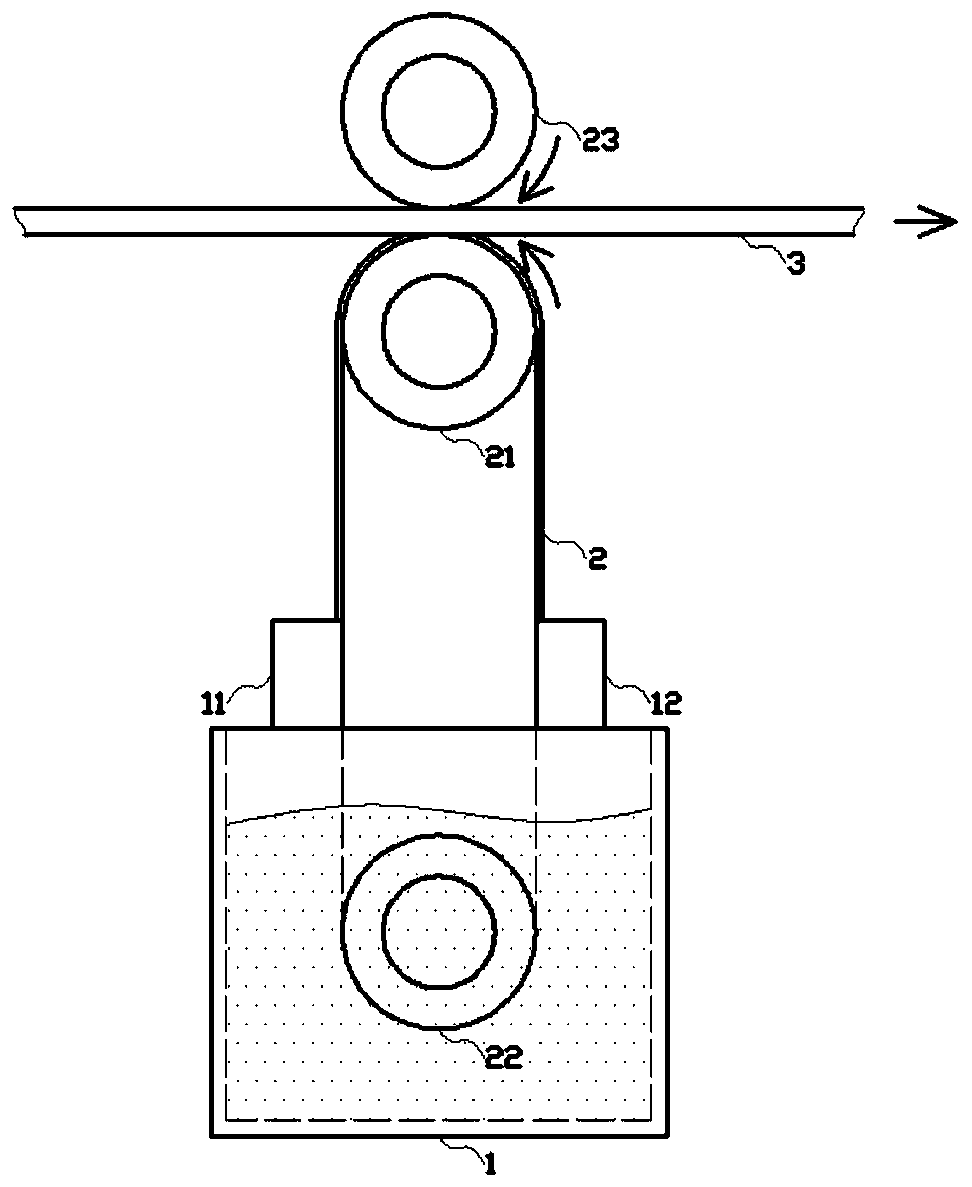

[0012] Such as figure 1 , figure 2 As shown in the embodiment, the viscose type textile cloth dedusting device is a kind of sticking and dedusting the surface of the textile cloth by attaching the viscose in the molten state to the sticking tape, and after the dust is removed, the solid viscose The glue is melted and reused, so as to achieve the effect of circulating dust removal device, which includes a gel module 1 and a delivery module 2; the gel module 1 includes a liquid storage tank, and the inside of the liquid storage tank is provided with liquid glue. The liquid glue uses hot-melt glue; the gel module 1 includes a temperature regulating device, and the temperature regulating device includes a cooling component 11 and a heating component 12; the cooling component 11 uses a cooling sheet, and a heat conducting plate is arranged on the cooling sheet, The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com