Device and method for separating iron shapes from castings in shells of wheel reducers

A wheel reducer and iron mold technology, which is applied to the device for separating the iron mold from the casting in the wheel reducer housing, the separation of the iron mold and the casting in the iron mold sand-covered casting wheel reducer housing, the device field, can Solve the problems that the iron mold and the casting in the wheel reducer shell cannot be separated, the casting is damaged, the vibrator is damaged, etc., and the cleaning process of the iron mold is simplified, the production process is shortened, and the damage is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

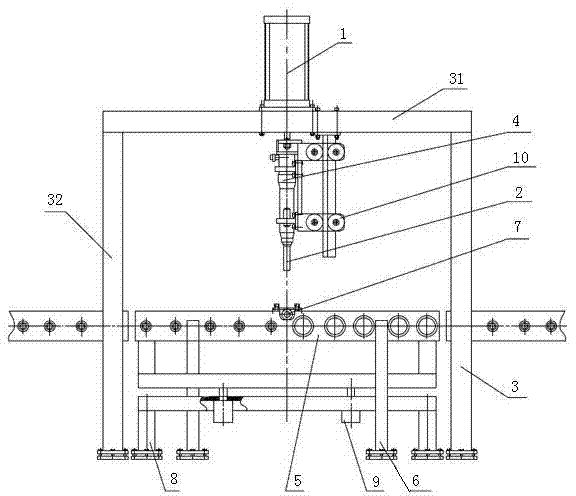

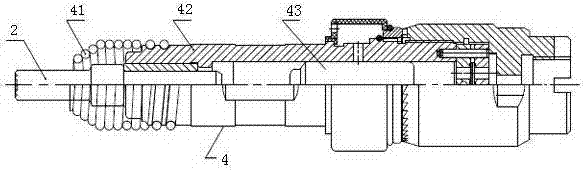

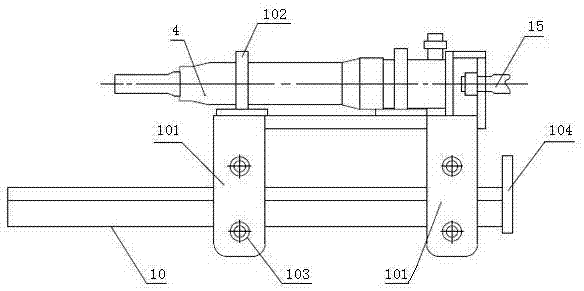

[0027] see Figure 1 ~ Figure 3 , this embodiment mainly includes ejection cylinder 1, ejector rod 2, frame 3, vibration device 4, iron-shaped conveying roller table 5, iron-shaped supporting pillar 6, iron-shaped positioning device 7, roller table receiving seat 8, roller table Lifting cylinder 9, ejector rod guiding mechanism 10, sand covering layer 11, sprue 12, iron mold 13, casting 14 and cylinder piston rod 15.

[0028] The roller table receiving seat 8 is directly installed on the ground below the frame 3, and the ejection cylinder 1 is fixedly installed on the upper plane of the upper beam 31 of the frame 3 with bolts. The frame 3, the roller table receiving seat 8 and the ejection cylinder 1 The center position coincides with the center point position of the whole device. The vibrating device 4 is located below the upper beam 31 of the frame 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com