Portable concrete pouring supporting device applied to building construction

A support device and portable technology, which is applied in the field of portable concrete pouring support devices for building construction, can solve the problems of affecting the pouring quality of connecting plates, uneven support force of wooden boards, and low work efficiency, and achieves small space occupation, easy movement and disassembly Easy operation and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

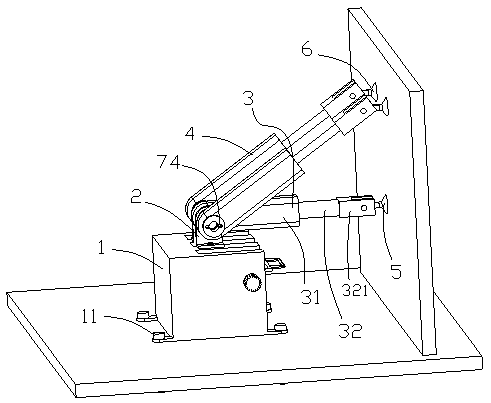

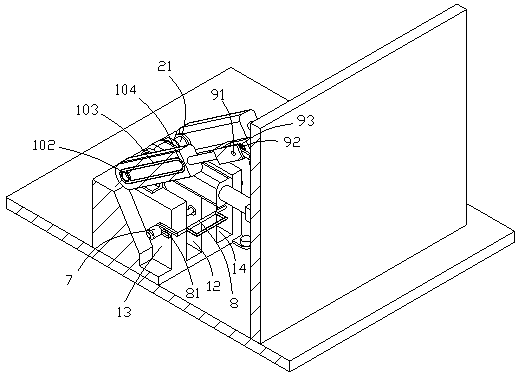

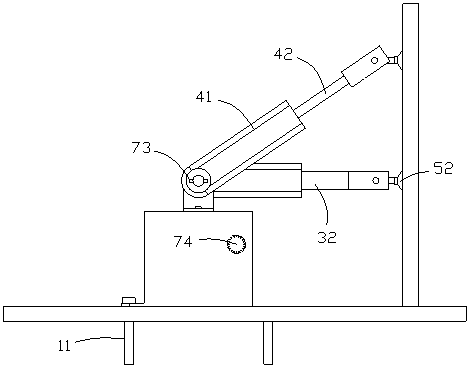

[0027] Such as Figure 1-6 As shown, a portable concrete pouring support device for building construction includes a base 1, a support frame 2 arranged on the base, a brace assembly, a first accommodation chamber 12, a second accommodation chamber 13, and a third accommodation chamber 14. The limit rod 7 and the handle 8, the base 1 can be connected to the ground to be constructed through the fixed column 11, and the fixed column can be a metal bolt; the support arm assembly can be turned up and down and set on the support frame Specifically, the brace assembly includes a center brace 3 and two side braces 4 arranged on the left and right sides of the center brace, a center brace 5 arranged on the end of the center brace, a center brace 5 arranged on the side brace The side support head 6 on the top, the first adjustment part for adjusting the turning angle of the center support head 5 relative to the center support arm 3 and the second adjustment part for adjusting the turnin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com