Control method of refrigerator assembling system and refrigerator assembling system

A control method and assembly system technology, which is applied in the control of refrigerator assembly systems and in the field of refrigerator assembly systems, can solve problems such as low reliability, time-consuming and labor-intensive, mismatch between component models and cabinet models, and achieve the effect of avoiding out-of-stock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

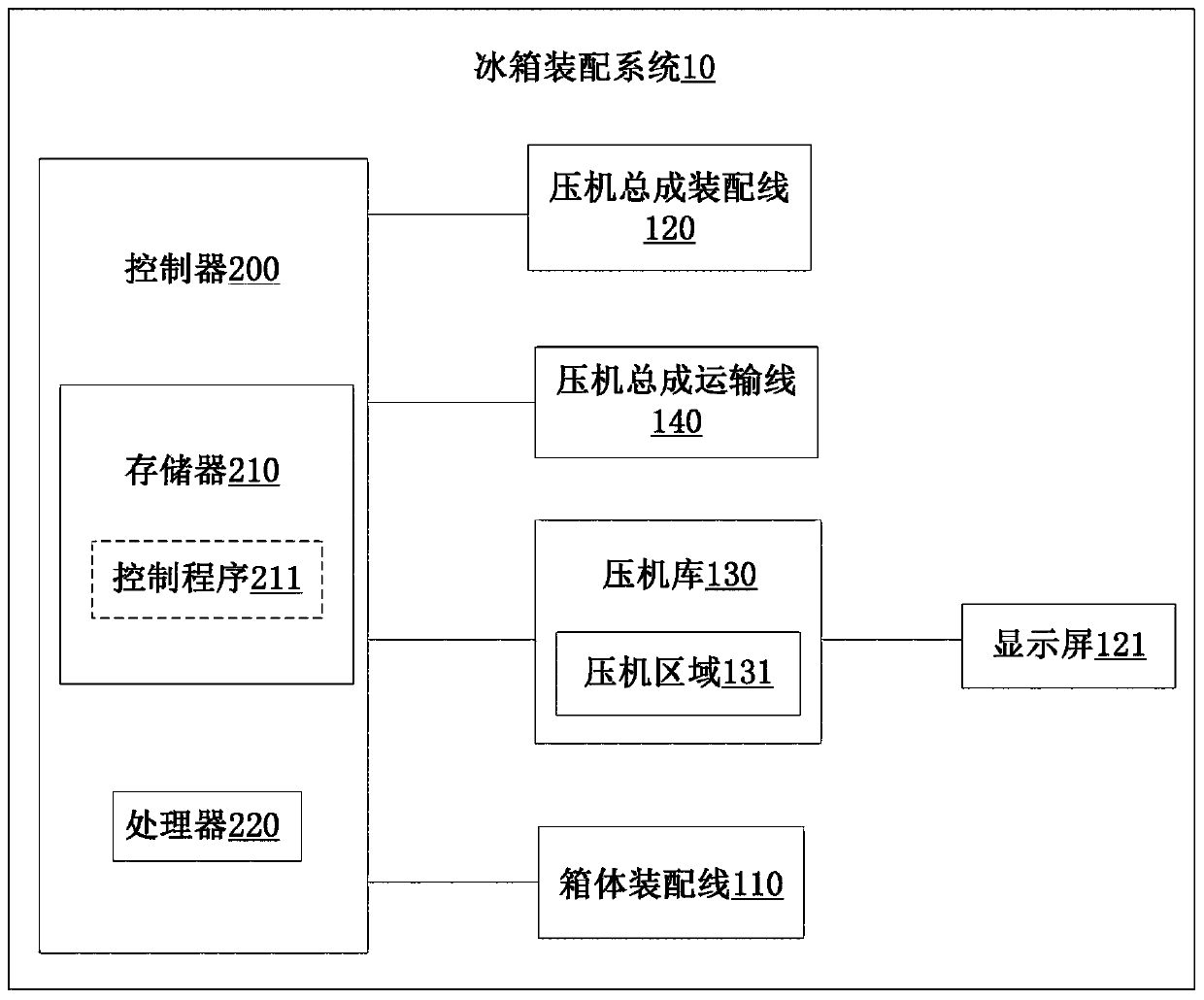

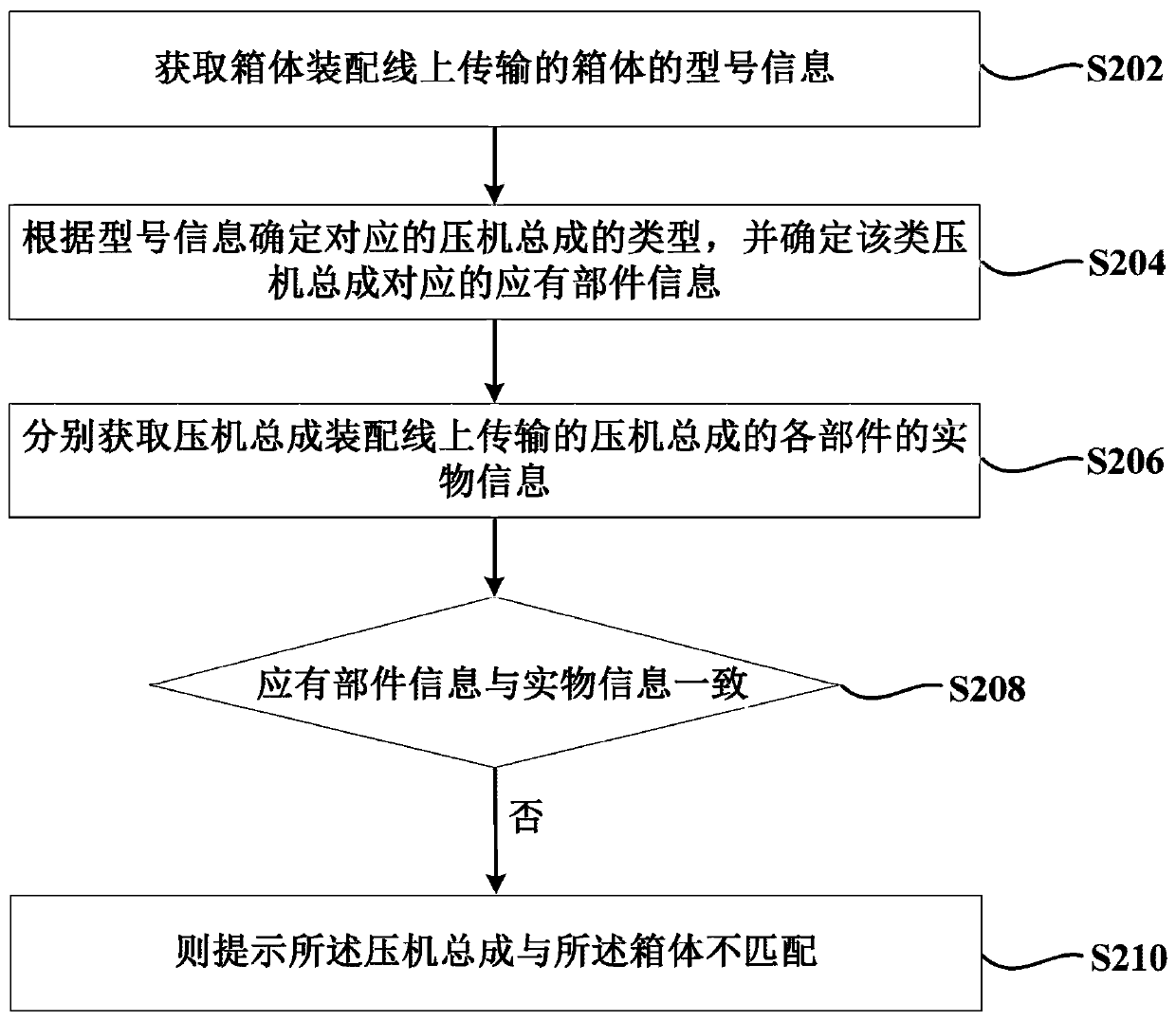

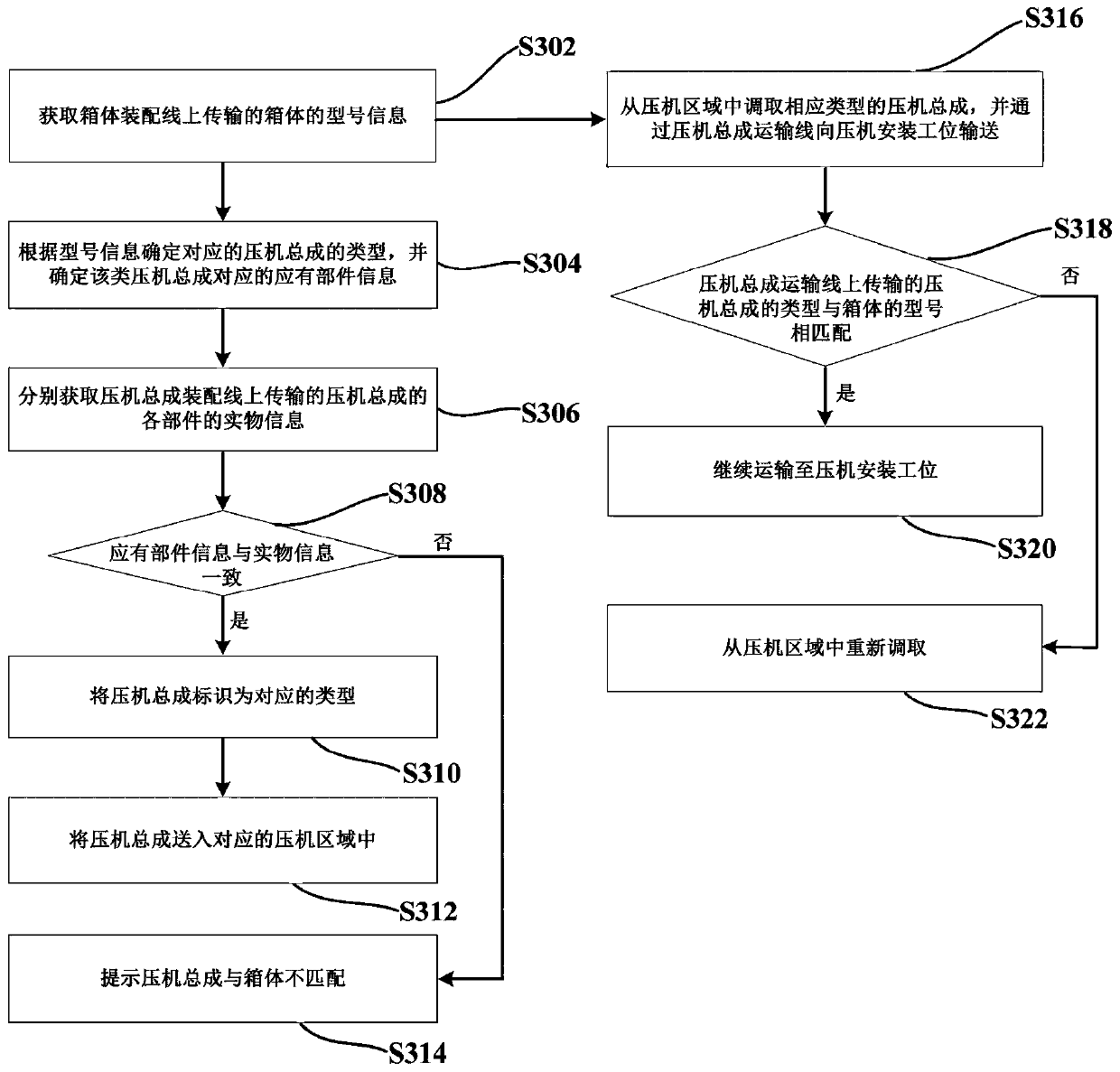

[0023] figure 1 It is a schematic block diagram of a refrigerator assembly system 10 according to an embodiment of the present invention. The refrigerator assembly system 10 of this embodiment may generally include: a controller, including a processor and a memory, wherein the memory stores a control program, and the control program is executed by the processor During execution, it is used to realize the control method of the refrigerator assembly system 10 provided according to this implementation.

[0024] The components of the compressor assembly in this embodiment may include: a compressor, a fan, a condenser and a bottom plate. In some other embodiments, the components of the compressor assembly may also include: a compressor and a bottom plate, or a compressor, a fan and a bottom plate. The components and types of components included in the press assembly depend on the model of the refrigerator box to be assembled.

[0025] The refrigerator assembly system 10 of this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com