Automatic power distribution method for charging pile based on linked list

A distribution method and automatic power technology, applied in charging stations, electric vehicles, electric vehicle charging technology, etc., can solve the problems of difficulty in meeting the frequency of use, poor power distribution of charging piles, and low charging occasions, etc., to achieve charging efficiency average, reduce the failure rate, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

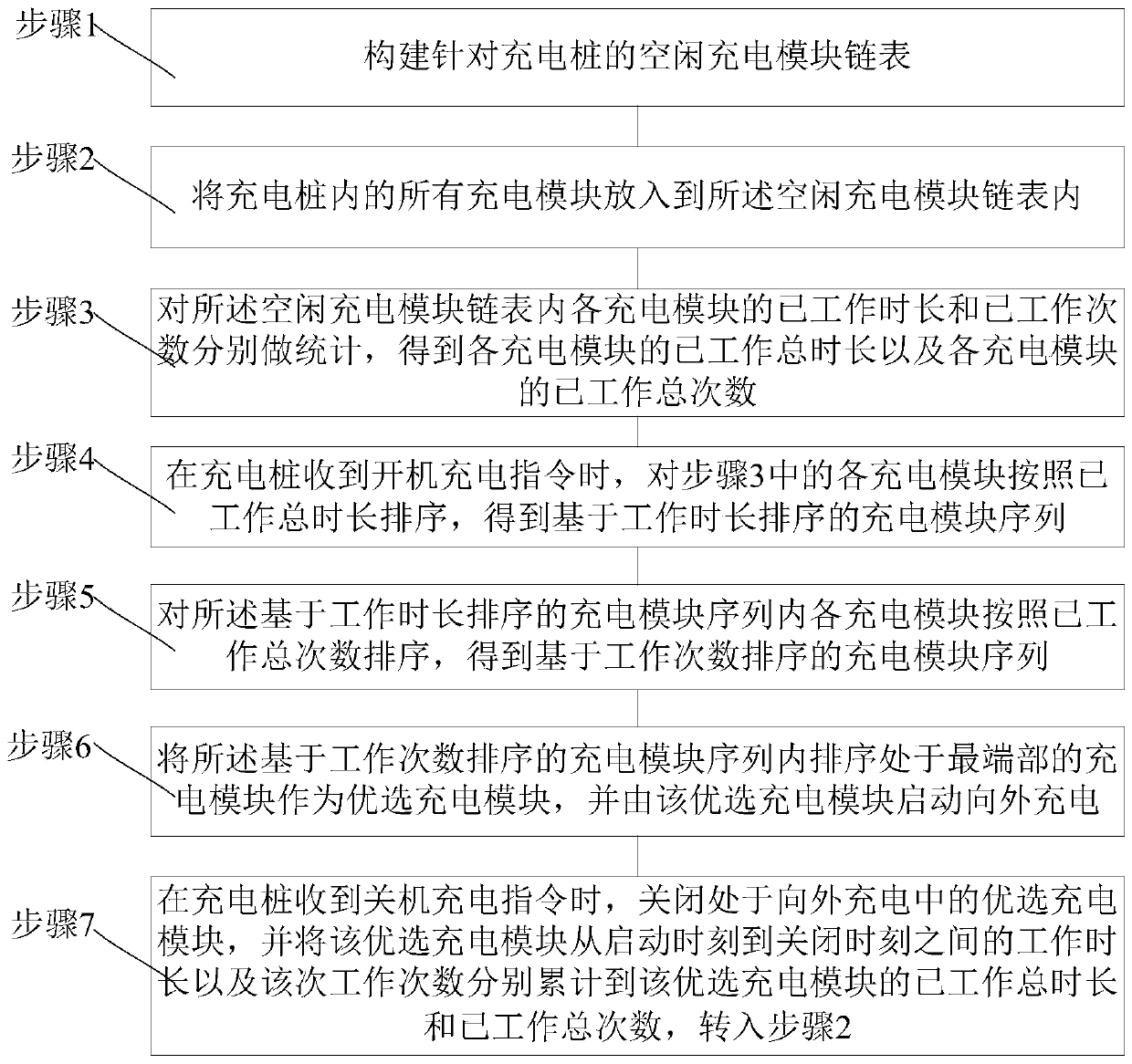

[0031] Such as figure 1 As shown, this embodiment provides a method for automatic power distribution of charging piles based on a linked list. The method for automatic power distribution of charging piles based on a linked list includes the following steps:

[0032] Step 1, build a linked list of idle charging modules for charging piles; wherein, the charging piles in this embodiment use DC charging piles;

[0033] Step 2, put all the charging modules in the charging pile into the free charging module linked list;

[0034] For example, suppose the total number of charging modules in the charging pile is N, N=8; the i-th charging module in the charging pile is marked as R i , 1≤i≤N; then, the N charging modules are put into the built-up linked list of idle charging modules;

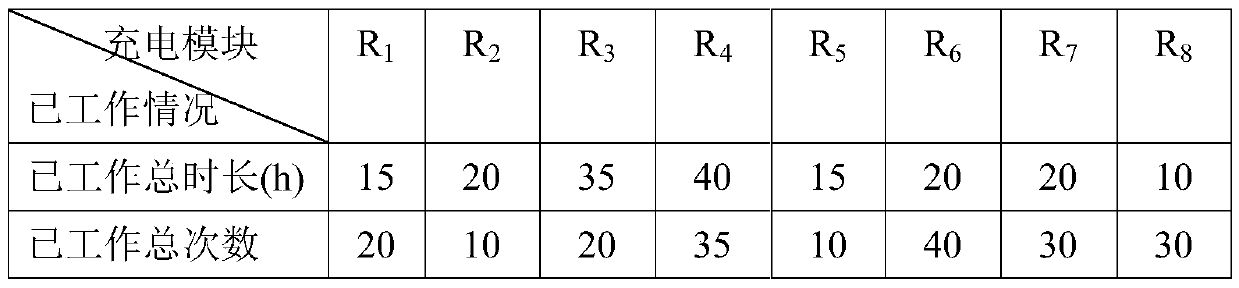

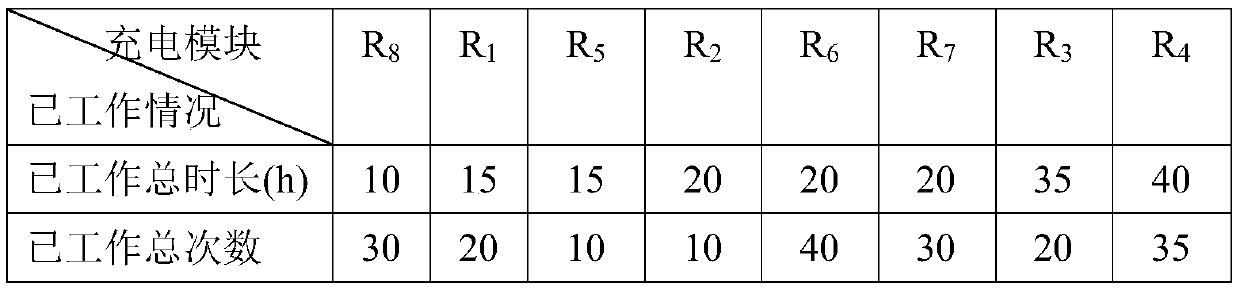

[0035] Step 3, make statistics on the working time and working tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com