A multi-stage buffer energy-absorbing device

An energy-absorbing device and energy-absorbing tube technology, which is applied in the field of rail vehicle collisions, can solve problems such as short action strokes and no emergency energy release devices, and achieve the effects of high reliability, rapid response, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to better understand the technical solutions of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

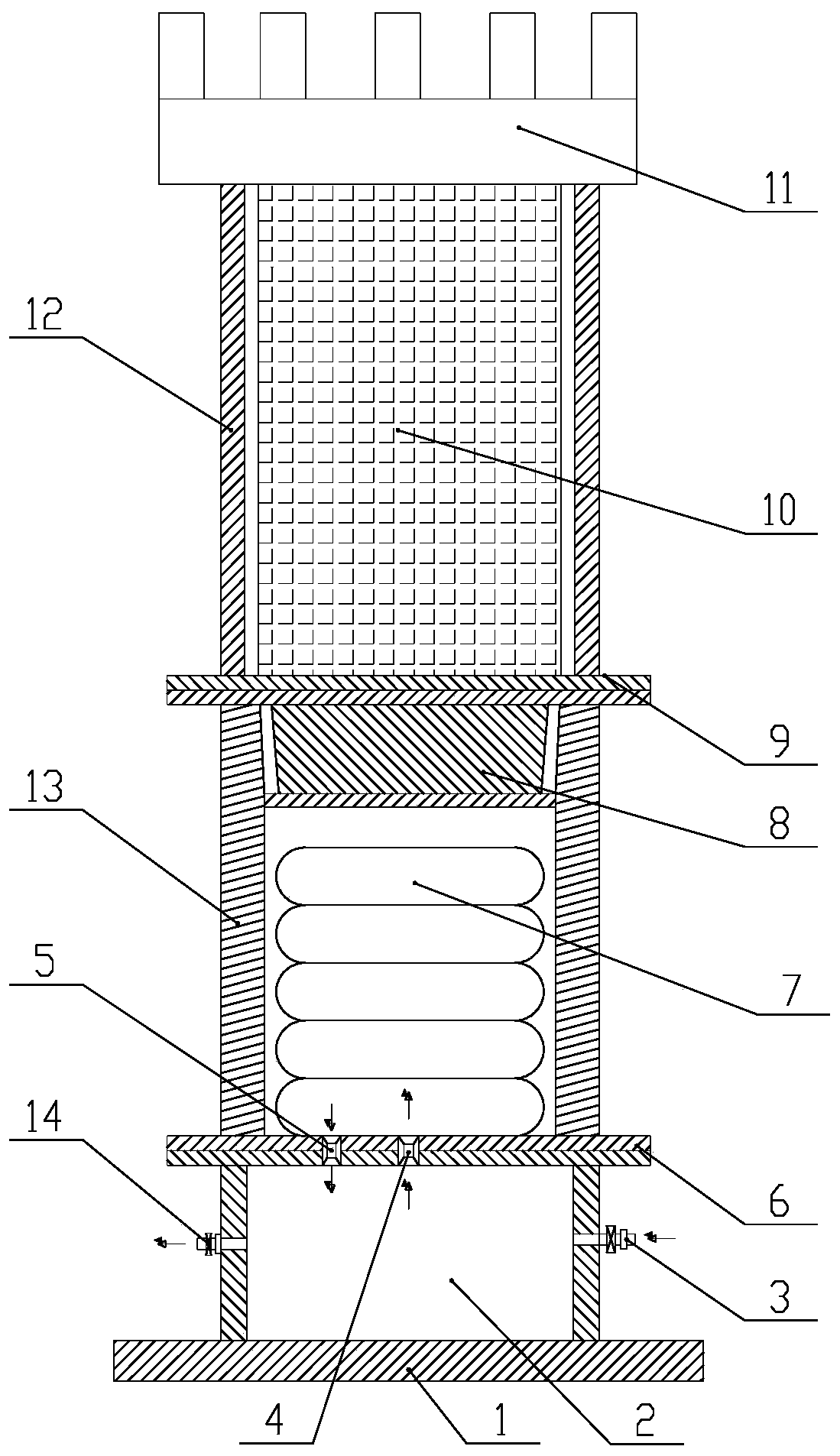

[0014] The present invention is a compressed gas multi-stage buffer energy-absorbing device, such as figure 1 Shown; The multi-stage buffer energy-absorbing device is installed on the front end of the train through the mounting plate 1. When the multi-stage buffer energy-absorbing device is in working condition, the high-pressure gas storage chamber 2 is first filled with gas through the air intake device 3, and then the high-pressure gas storage chamber is discharged through the intake check valve 4 on the second compound flange 6. The gas in the chamber 2 is charged into the buffer air spring 7 . When bumping into the anti-climbing tooth 11, the whole device is subject to a huge impact force, and what is squeezed is the primary energy-absorbing tube 12 connected to the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com