Anti-snagging fleece knitted fabric

A knitted fabric and anti-snag technology, which is applied in protective clothing, special outerwear, textiles and papermaking, etc., can solve the problems of discomfort for the wearer and affecting the appearance of the clothes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

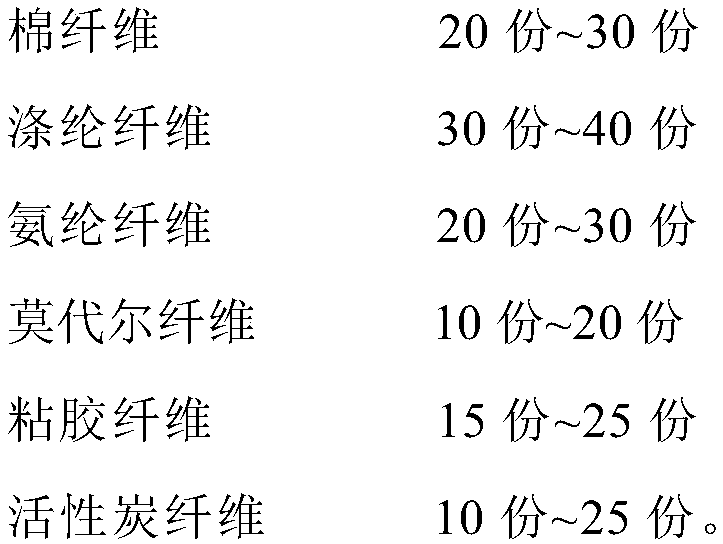

[0026] An anti-snag sweater knitted fabric of this embodiment includes a fabric body and a waxed layer arranged on the surface of the fabric body, and the fabric body is made of the following components in parts by weight:

[0027]

[0028] In this embodiment, the linear density of the viscose fiber is 0.6 dtex.

[0029] In this embodiment, the linear density of activated carbon fibers is 0.5dtex.

[0030] The linear density of the cotton fibers is 0.4 dtex.

[0031] The linear densities of the polyester fiber and the spandex fiber are both 0.3dtex.

[0032] The linear density of the modal fiber is 0.7dtex.

[0033] In this embodiment, the thickness of the waxed layer is set to 0.5 mm.

Embodiment 2

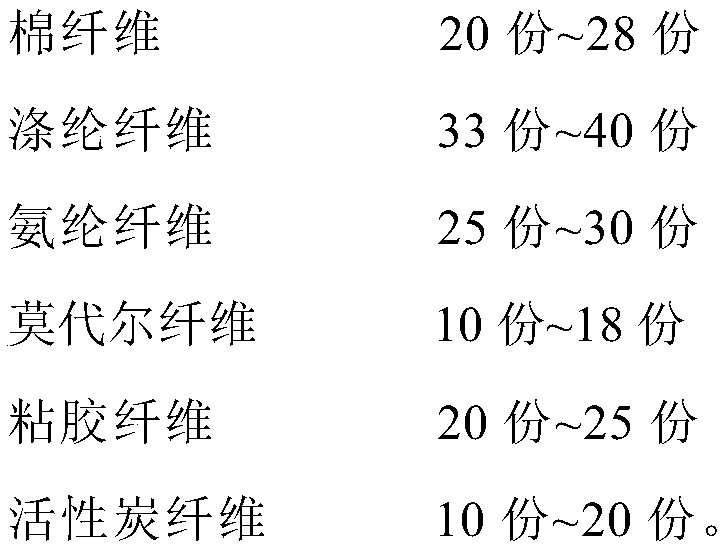

[0035] An anti-snag sweater knitted fabric of this embodiment includes a fabric body and a waxed layer arranged on the surface of the fabric body, and the fabric body is made of the following components in parts by weight:

[0036]

[0037] In this embodiment, the linear density of the viscose fiber is 0.5 dtex.

[0038] In this embodiment, the linear density of activated carbon fibers is 0.4dtex.

[0039] The linear density of the cotton fiber is 0.3dtex.

[0040] The linear densities of the polyester fiber and the spandex fiber are both 0.2dtex.

[0041] The linear density of the modal fiber is 0.6dtex.

[0042] In this embodiment, the thickness of the waxed layer is set to 0.4mm.

Embodiment 3

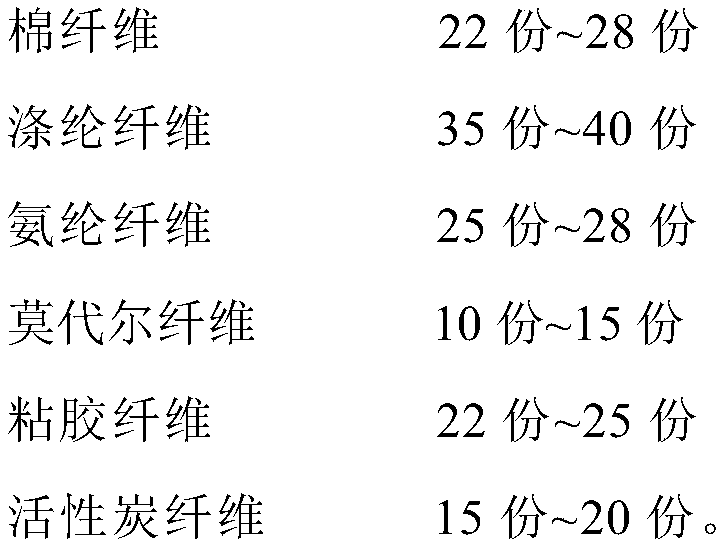

[0044] An anti-snag sweater knitted fabric of this embodiment includes a fabric body and a waxed layer arranged on the surface of the fabric body, and the fabric body is made of the following components in parts by weight:

[0045]

[0046] In this embodiment, the linear density of the viscose fiber is 0.8dtex.

[0047] In this embodiment, the linear density of activated carbon fibers is 0.7dtex.

[0048] The linear density of the cotton fibers is 0.6 dtex.

[0049] The linear densities of the polyester fiber and the spandex fiber are both 0.5 dtex.

[0050] The linear density of the modal fiber is 0.8dtex.

[0051] In this embodiment, the thickness of the waxed layer is set to 0.6mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com