Fidelity sampling device applied to shale gas and method for thermal analysis of shale gas

A sampler and shale gas technology, which can be used in earth-moving drilling, extraction of undisturbed core devices, etc., can solve the problems of gas escape and analysis results that cannot fully reflect the gas content of the target layer, so as to improve the accuracy and improve the The effect of sampling operation efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0109] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

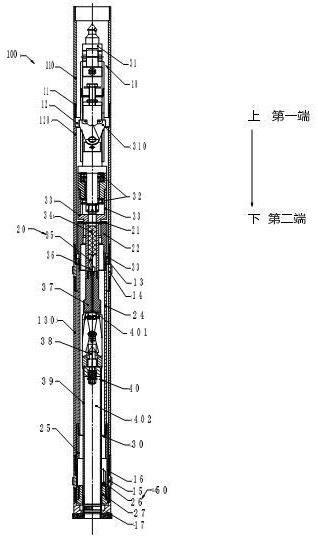

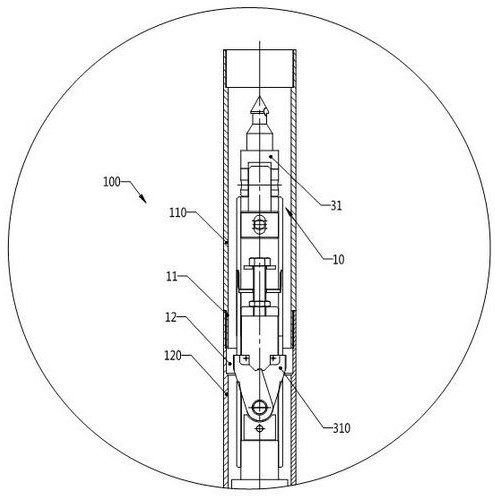

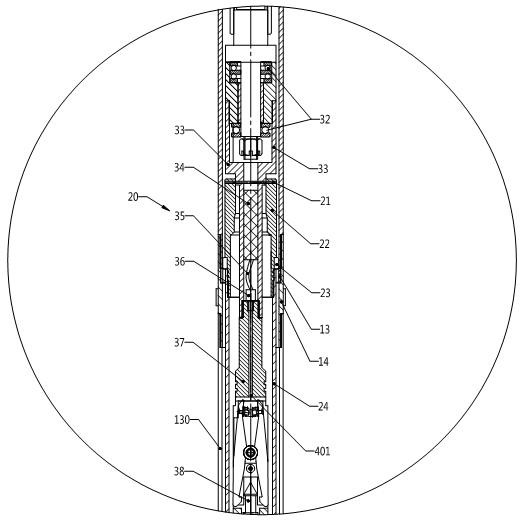

[0110] Append figure 1 In the orientation shown, a first end of each of the above side member, the orientation of the second end of each member, in the present application the orientation of the word in order to make description clear and complete description only.

[0111] Shale salvage from the sampling tool to the surface, object of the rock sample layer storage environment has changed greatly, causing part of the gas is expelled from the rock samples, which led to the analysis result can not fully reflect the real objec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com