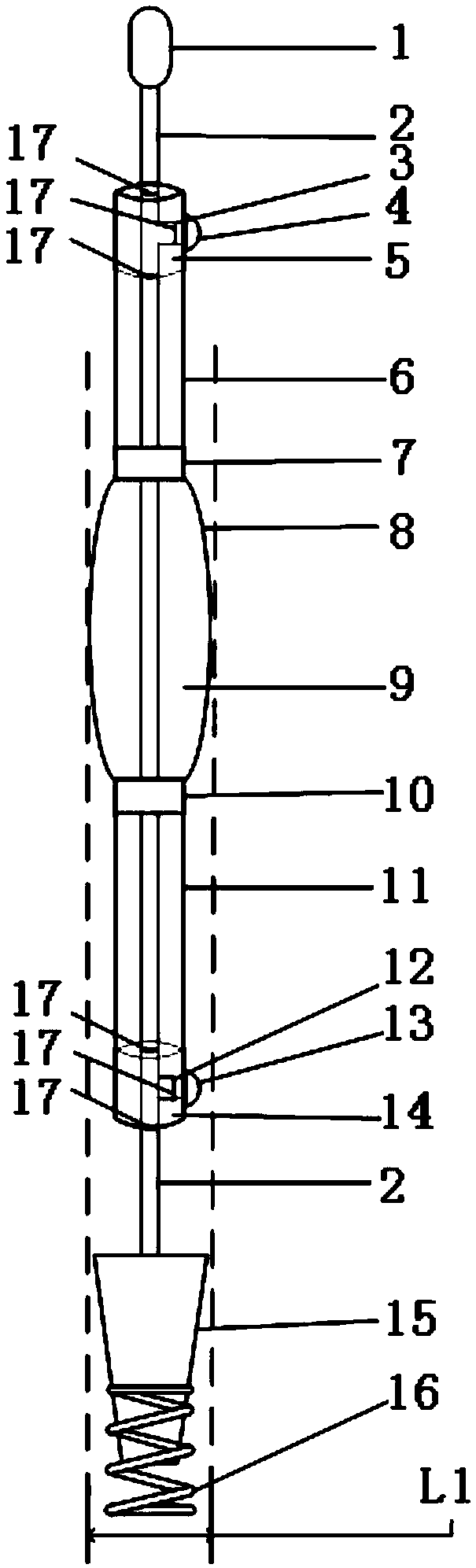

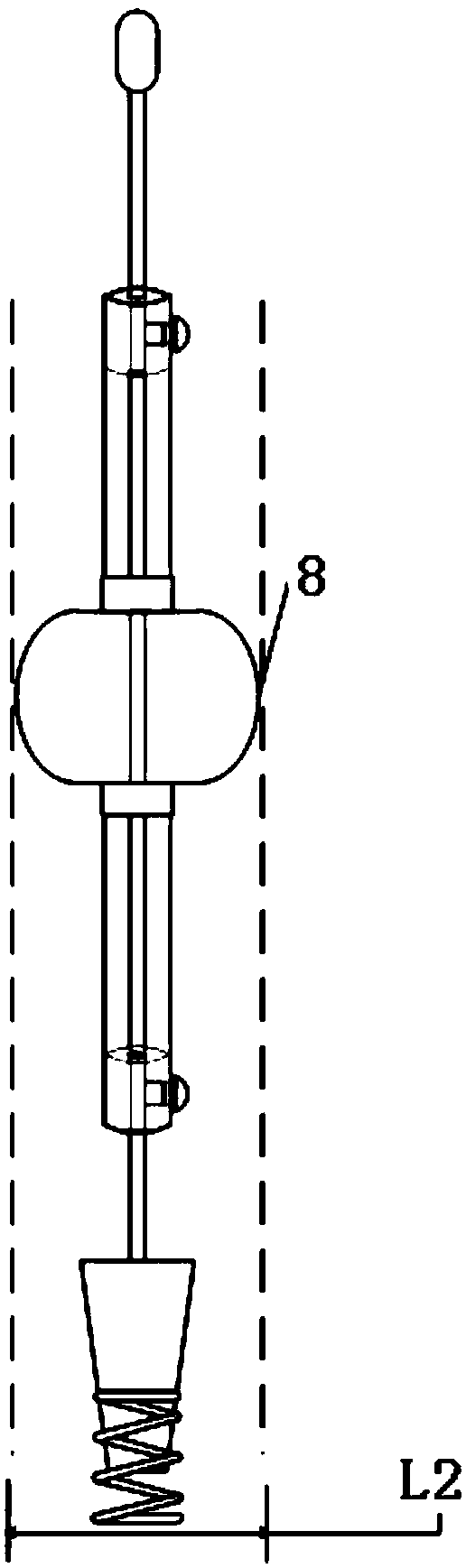

Throw-in type drill rod drift diameter gauge and application method thereof

An investment-type, caliper technology, applied in the field of petroleum exploration, can solve the problems such as the inability to adapt to conventional variable diameter drill pipes, and the inability to detect the residual mud cake on the wall. Simple to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0068] Throwing the device into the water hole at the high-end side of the drill pipe placed vertically or inclined at a large angle without initial velocity can ensure that the device can fall freely inside the drill pipe. The device falls under gravity. If it encounters obstacles during the fall , failing to reach the exit at the bottom of the drill pipe, it means that the drill pipe does not meet the requirements for entering the well, and needs to be moved from the working area to the non-working area for follow-up treatment, and the inner wall surface can be cleaned before entering the well.

example 2

[0070] Throwing the device into the water hole at the high-end side of the drill pipe placed vertically or inclined at a large angle without initial velocity can ensure that the device can fall freely inside the drill pipe. The device falls under gravity. Then the whole device goes down to the bottom outlet of the drill pipe smoothly. At this time, the guide head and the buffer spring drill out the low-end water hole. The buffer spring touches the ground first, and then the lower pin drills out the low-end water hole. The lower water hole was taken out smoothly, which indicated that the inner diameter of the drill pipe was normal, which met the requirements for running into the well and could be put into the well.

[0071] Except for the rubber oil bag, the device is made of metal, or other materials with the same strength as the metal. This device does not make specific requirements on the size of each part of the device, but only provides the idea of the device. It adopts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com