Logistics sorting mechanical arm device

A mechanical arm and manipulator claw technology, applied in the field of logistics sorting equipment, can solve the problems of low sorting efficiency, large labor force, time-consuming and laborious, etc., and achieve the effect of improving sorting accuracy, preventing external collision, and reducing turning force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

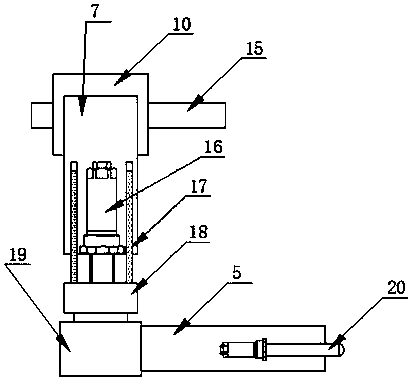

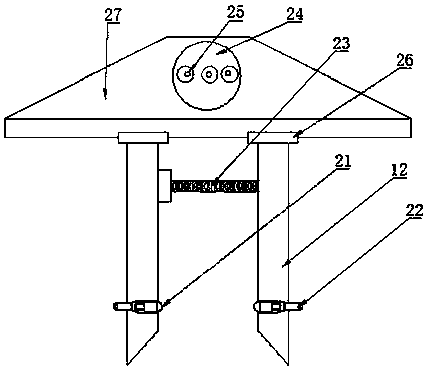

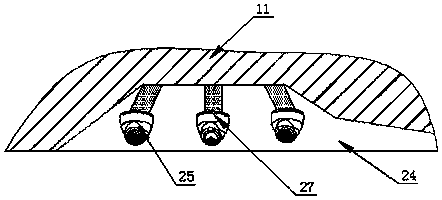

[0031] see Figure 1-6 , in an embodiment of the present invention, a logistics sorting mechanical arm device includes an installation chassis 4, an arm rotation mechanism 2, an arm telescopic mechanism 9, and a mechanical claw grabbing mechanism 6, wherein the arm rotation mechanism is used on the installation chassis The rotatable support of the mechanism 2 is provided with an arm telescopic mechanism 9, and the front end of the arm telescopic mechanism 9 is provided with the mechanical claw grasping mechanism 6; it is characterized in that,

[0032] An overturning mechanism is also arranged between the mechanical claw grasping mechanism 6 and the output end of the arm telescoping mechanism;

[0033] The turning mechanism can rotate around the central telescopic axis of the arm telescopic mechanism, so as to make the products to be sorted reversed; and the turning mechanism can telescopically move in a direction parallel to the telescopic direction of the arm telescopic mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com