Automatic temperature adjustment textile roll device

A technology of temperature regulation and rolling, applied in textile and papermaking, strip winding, transportation and packaging, etc., can solve problems such as affecting the quality of finished products, rising temperature of textile fabrics, and limited scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

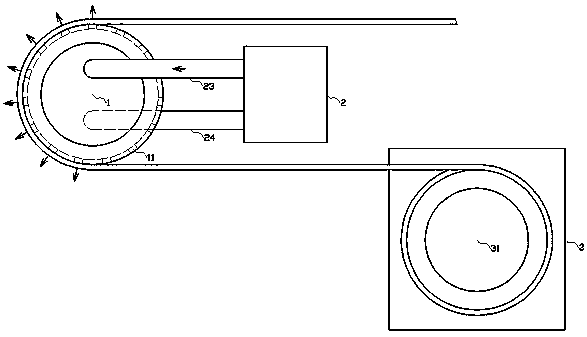

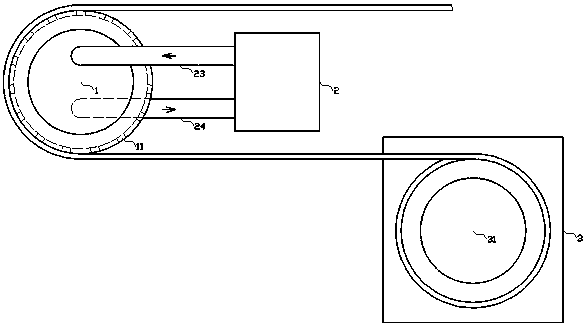

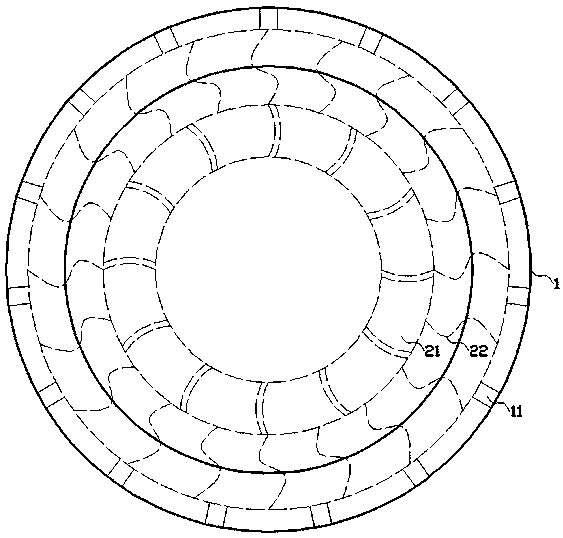

[0012] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0013] Such as figure 1 , figure 2 , image 3 As shown in the embodiment, the automatic temperature adjustment textile roll device is a kind of automatic adjustment of the state of the air outlet through timely monitoring of the temperature of the textile cloth, so that when the temperature of the textile cloth is too high, it can quickly ventilate and dissipate heat. When the temperature is too low, frictional heat is generated to automatically adjust the temperature of textile fabrics. It includes a temperature control module 1, a ventilation module 2 and a transmission module 3; the temperature control module 1 includes a positioning roll, and the positioning roll The outer side of the roller is in contact with the textile fabric, and the positioning roller is connected to the transmission module 3 through the textile fabric; the inside of the positioning ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com