A method of grouting post-construction segment wall of a full-section shield tunnel in hard rock stratum

A technology of shield tunneling and grouting behind the wall, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

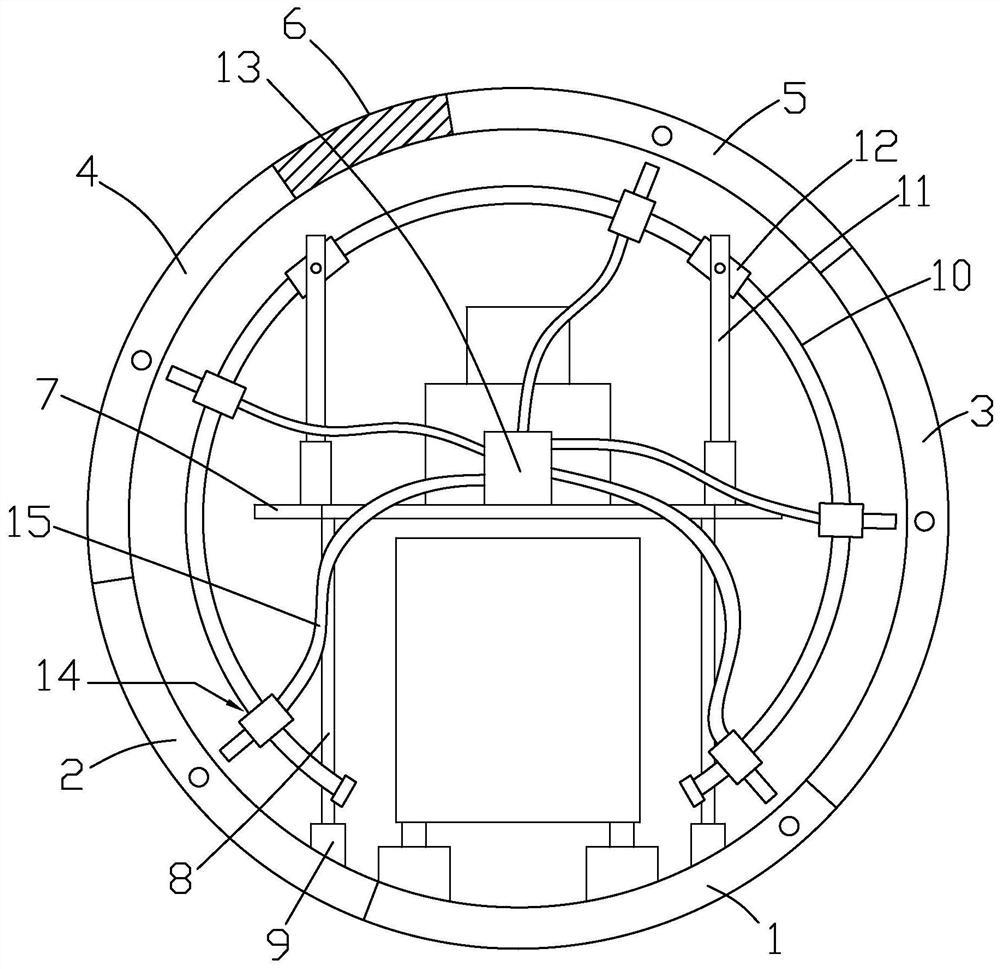

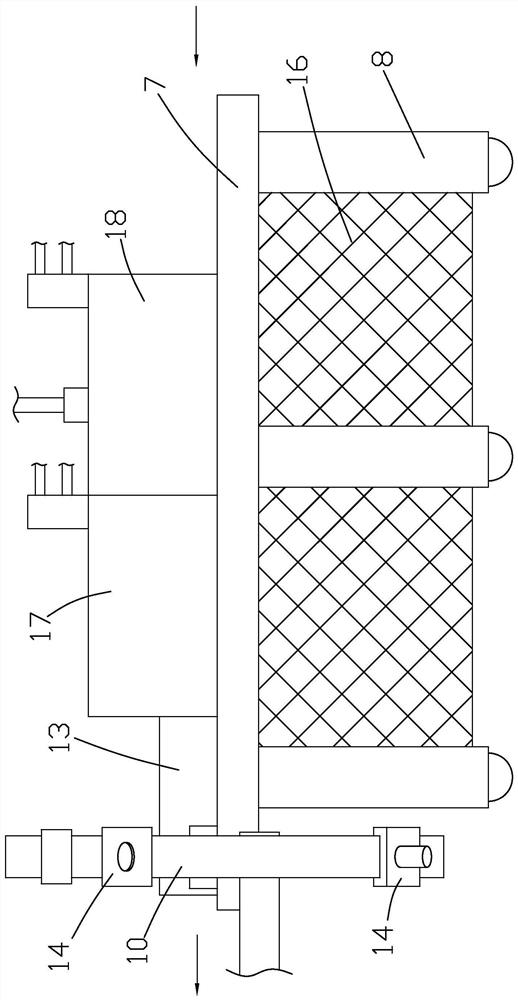

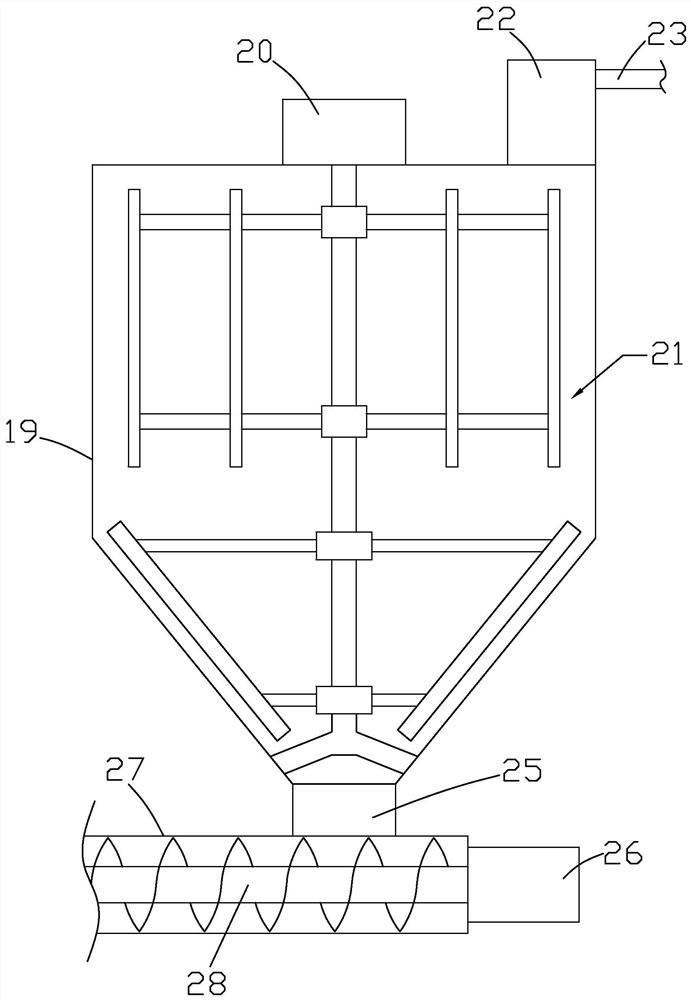

[0048] like Figure 1 to Figure 6 Shown, be the method for grouting after the construction segment wall of a kind of full-section hard rock formation shield tunnel of the present invention, comprise the steps:

[0049] 1) Shield machine installation

[0050] First, determine the construction path of the shield tunnel in hard rock formation according to the design requirements, and select a shield machine of appropriate size, put the shield machine into the launch shaft for installation and positioning, and then test run the shield machine to check the work of the shield machine conditions, and do a good job of pre-construction preparations, so that the grouting platform 7 can be seamlessly connected with the shield machine, so that the two do not affect each other when they work, and at the same time, the effect of post-grouting on the segment wall is improved to meet the Construction of shield tunnels of different sizes;

[0051] Since the shield machine is designed in an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com