Air outlet device and air fan

A technology for air outlet devices and fans, which is applied to pump devices, parts of pumping devices for elastic fluids, and non-variable pumps, etc. It can solve the problems of low air volume and wind speed of fans, and achieve short acceleration time, Optimized wind performance and high wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

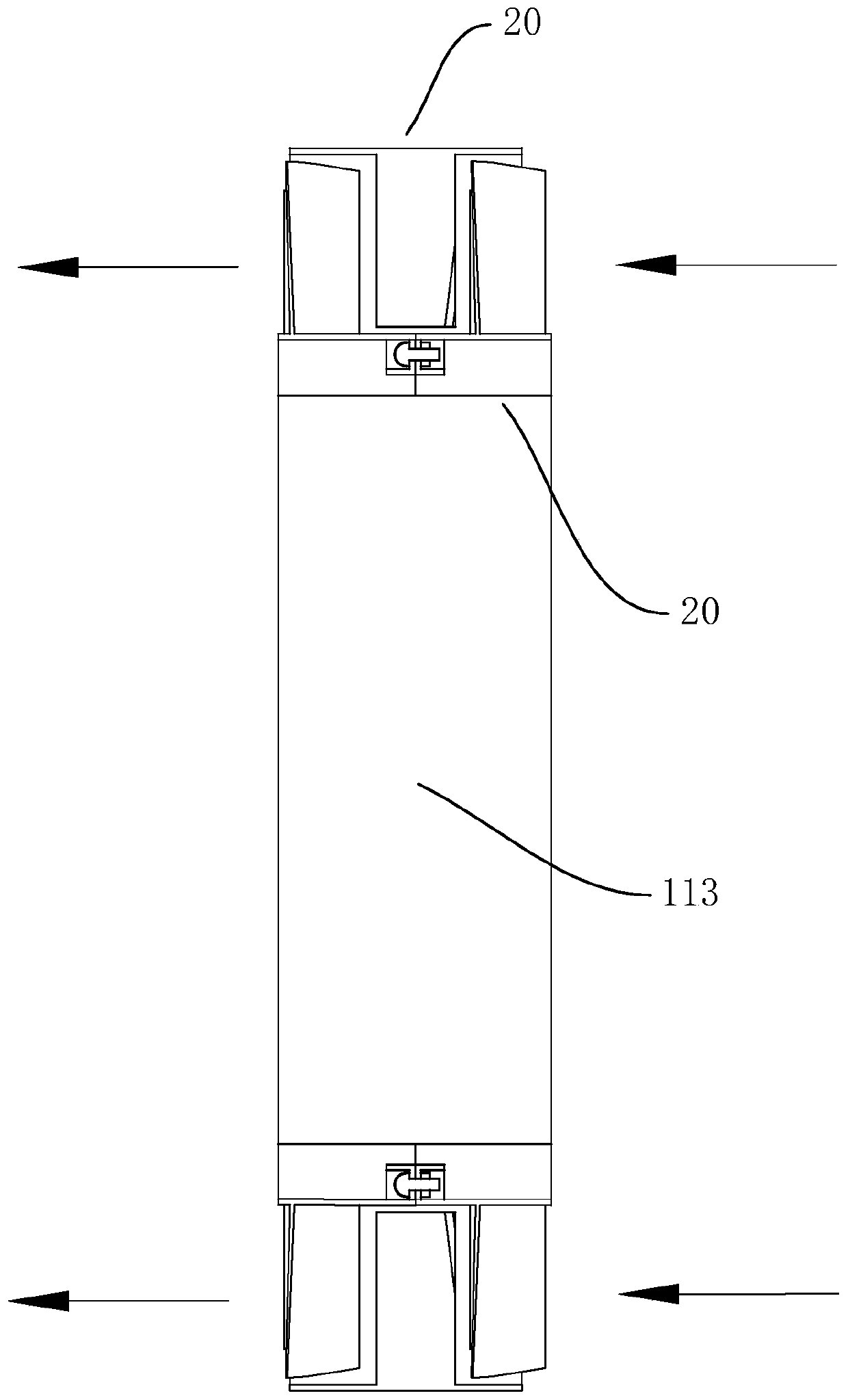

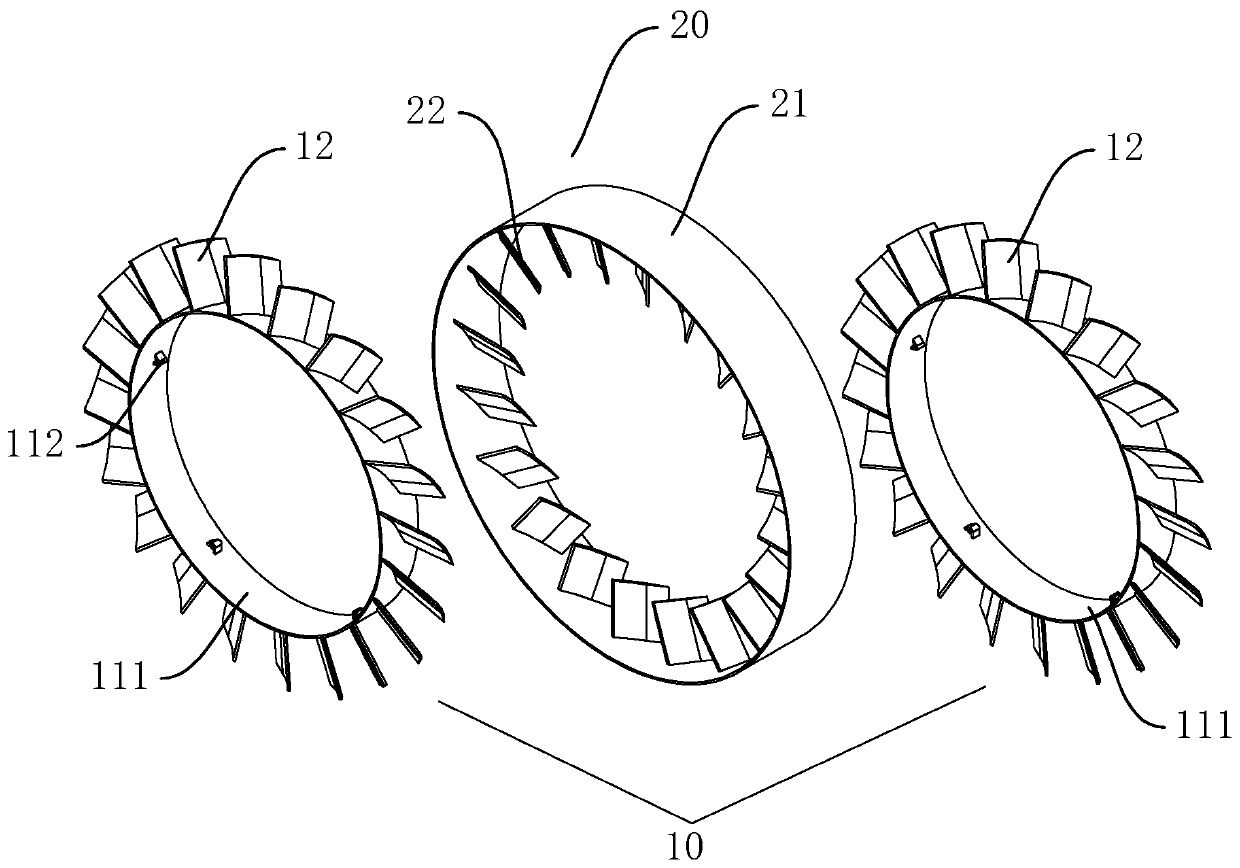

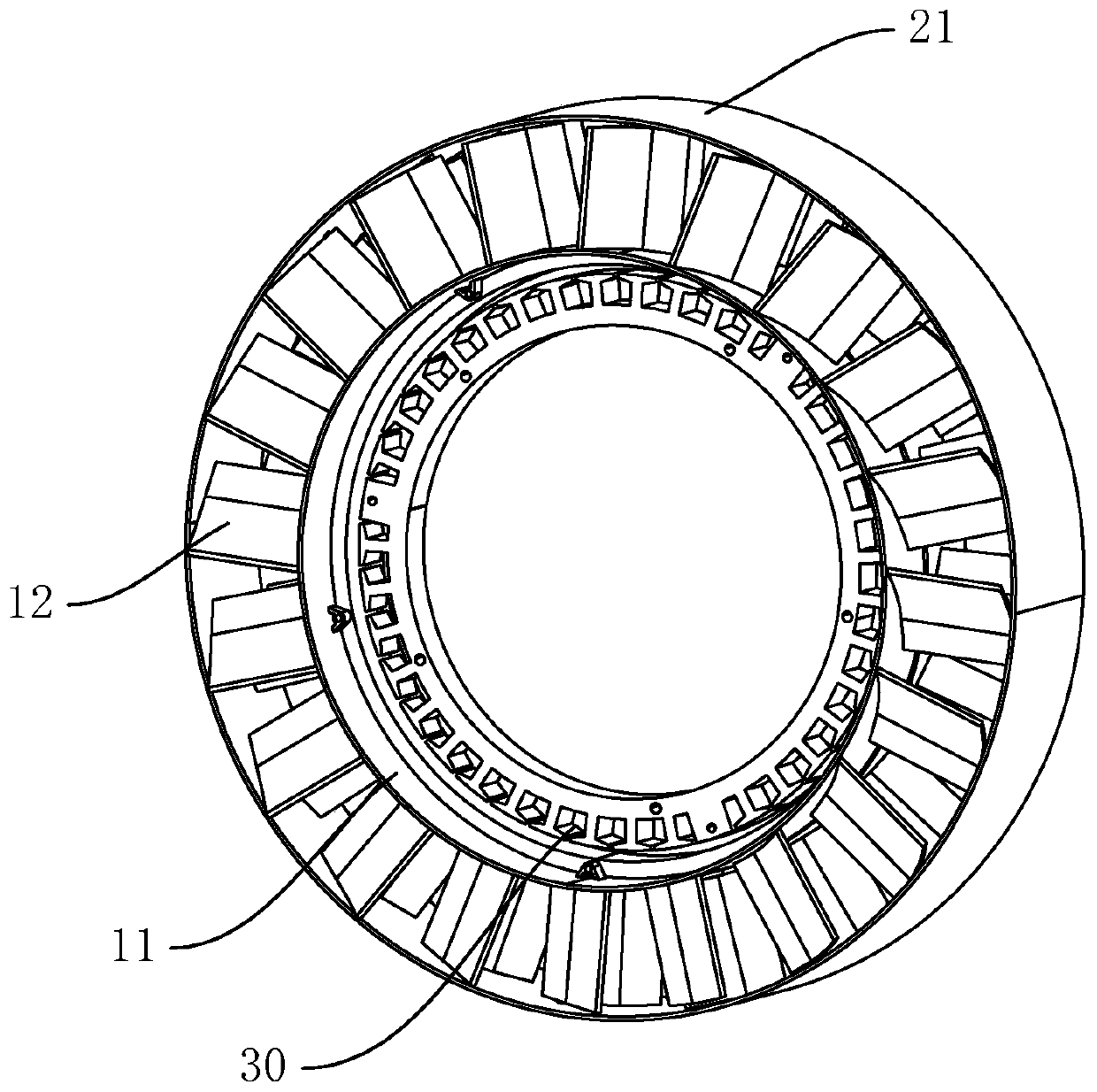

[0033] refer to Figure 1 to Figure 4 , the air outlet device in this embodiment includes a first air outlet 10 and a second air outlet 20, the first air outlet 10 and the second air outlet 20 are arranged alternately in sequence, and the first air outlet 10 includes a first air outlet The base 11 has a number of first fan blades 12 arranged along the edge of the first base 11; the second air outlet 20 includes a second base 21, and a number of second fan blades 22 are arranged along the edge of the second base 21. The blades 12 and the second blades 22 are alternately arranged in sequence along the axial direction of the first base body 11 or the second base body 21, the direction of the windward side of the adjacent first blades 12 and the second blades 22 is opposite, and the first air outlet part 10 It can be rotated relative to the second air outlet part 20 .

[0034] Because the first fan blades 12 and the second fan blades 22 are arranged alternately in sequence, and t...

no. 2 example

[0045] refer to Figure 5 The difference between this embodiment and the first embodiment is that the second base 21 includes no less than two second units 211, two adjacent second units 211 are docked and detachably connected, and multiple first units 111 are sequentially connected along the arrangement direction of the first fan blades 12 and the second fan blades 22 to form the second base body 21 , and the inner surface of each second unit 211 is connected with the second fan blades 22 . By segmenting the second base body 21, the installation difficulty of the air outlet device is further reduced. Several second installation blocks 212 can be arranged along the outer surface of the second base body 21, second installation blocks 212 are provided with second installation holes, the connection between the second installation blocks 212 is the same as the connection between the first installation blocks 112 the same way.

[0046] Preferably, no less than two rows of first f...

no. 3 example

[0048] refer to Figure 6 The difference between this embodiment and the second embodiment is that the first base body 11 and the second base body 12 are spliced structures, the first base body 11 is composed of three first units 111, and each first unit 111 has a A row of first fan blades 12 is connected, the second base body 21 is composed of two first units 211, and each second unit 211 is connected with a row of second fan blades 22, the first fan blades 12 and the second fan blades 22 alternate arrangements. By arranging both the first base body 11 and the second base body 21 in a spliced structure, the convenience of processing and assembling the air outlet device is further improved, and the production cost is reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com