Launch section vibration attenuation and orbital section vibration isolation integrated load supporting device

A supporting device and vibration isolation technology, which is applied to the functional characteristics of springs/shock absorbers, supporting machines, engine bases, etc., can solve the problems of single increase of bearing capacity, inability to achieve variable stiffness adjustment, and reduced reliability, etc., to achieve low-level The natural frequency distribution is compact, the effect of improving the on-orbit working environment requirements and reducing the vibration response peak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the accompanying drawings and examples.

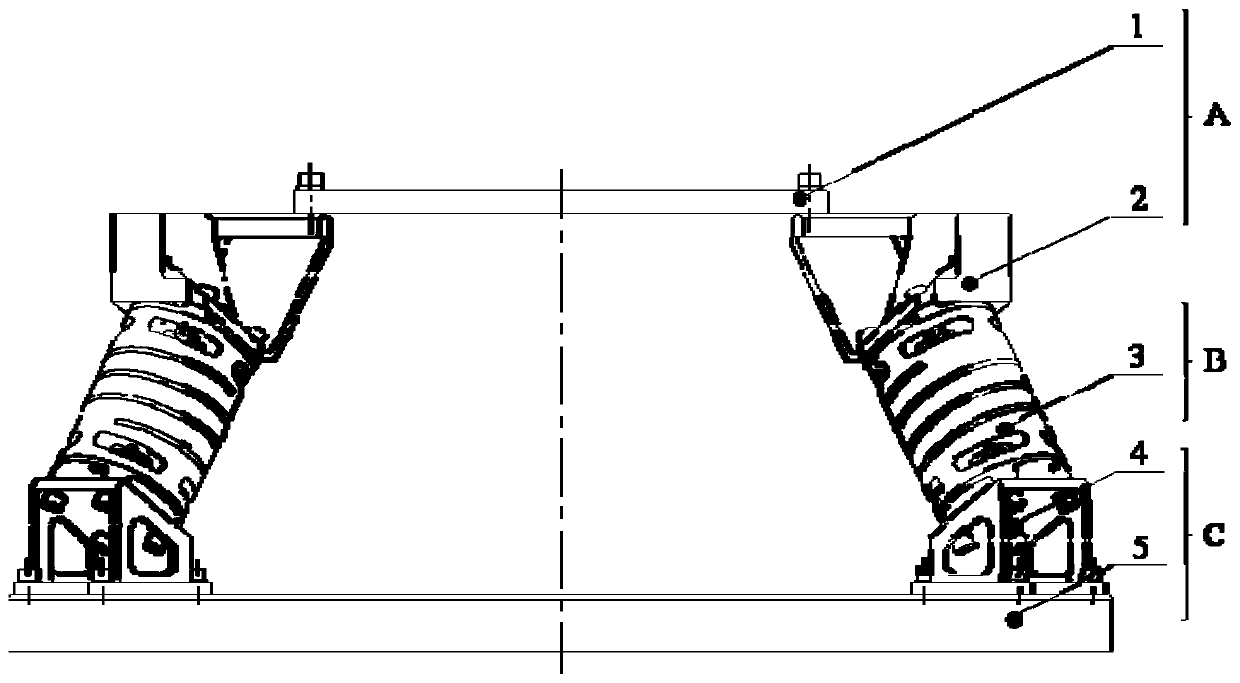

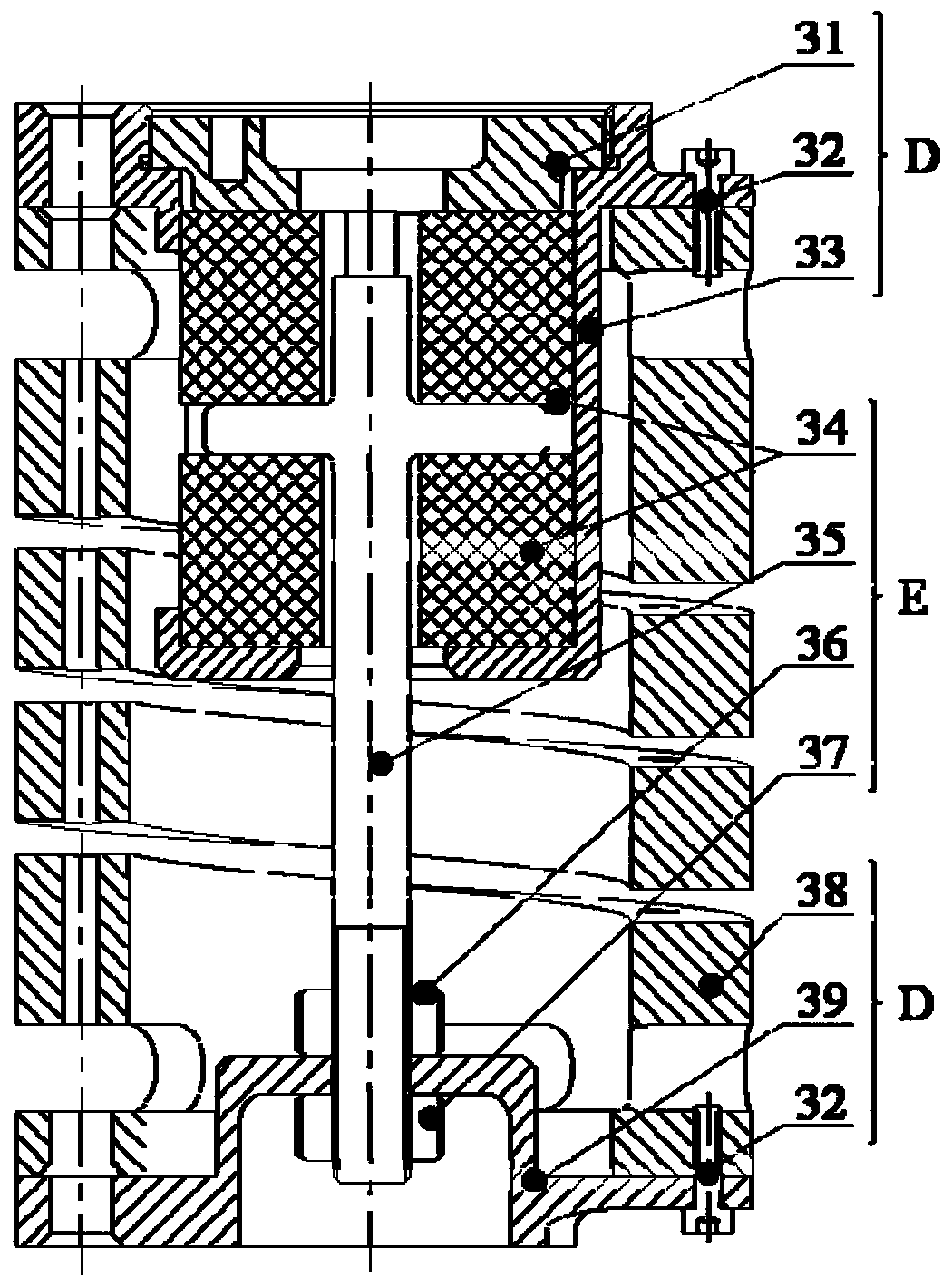

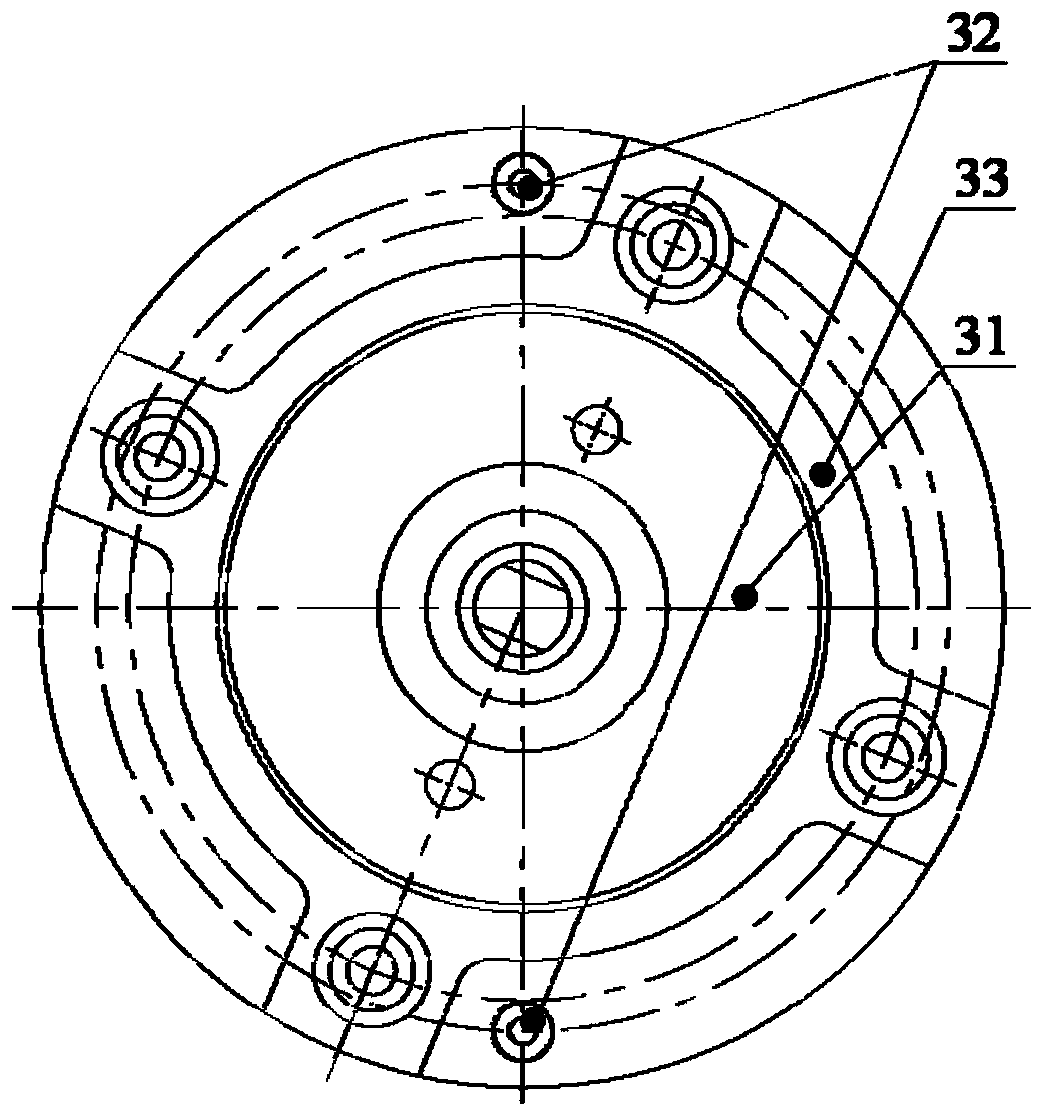

[0031] This embodiment provides a load support device that integrates vibration reduction in the launch section and vibration isolation in the orbit section. In order to overcome the problem that the existing vibration isolation device has a wide distribution of low-order modes and is easy to resonate with the spacecraft structure, The load support device adopts a three-way equal stiffness layout design in space to realize the concentrated distribution of the low-order modes of the load support device and effectively avoid the frequency of the spacecraft structure itself; at the same time, in order to overcome the inability to adjust the stiffness of the existing passive The rigidity adjustment method is complicated and low in reliability. Passive variable stiffness design is adopted. Through the two-way adjustment design, the variable stiffness requirement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com