Flowmeter calibration system with multiple calibration lines and calibration method based on system

A technology for calibrating system and flowmeter, applied in the field of multi-calibration line flowmeter calibration system, can solve problems such as high cost and low calibration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

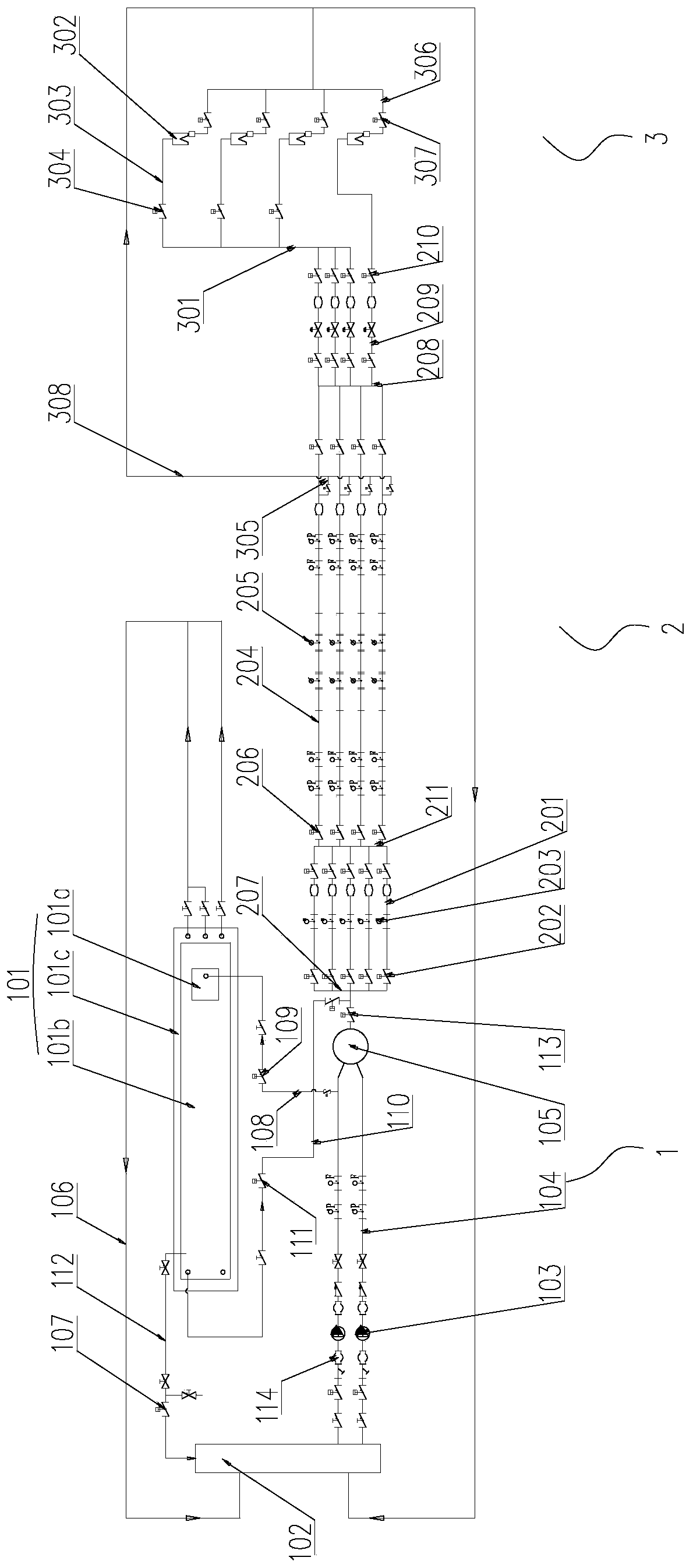

[0050] Example 1, such as figure 1 As shown, a flow meter calibration system with multiple calibration lines includes a water supply mechanism 1 and a calibration mechanism 2;

[0051] The water supply mechanism 1 includes a reservoir 102. The reservoir 102 is connected with L first water supply pipes 104, where L is a natural number. The water outlet ends of all the first water supply pipes 104 are connected to the same surge tank 105. A water pump 103 is installed on a water supply pipe 104;

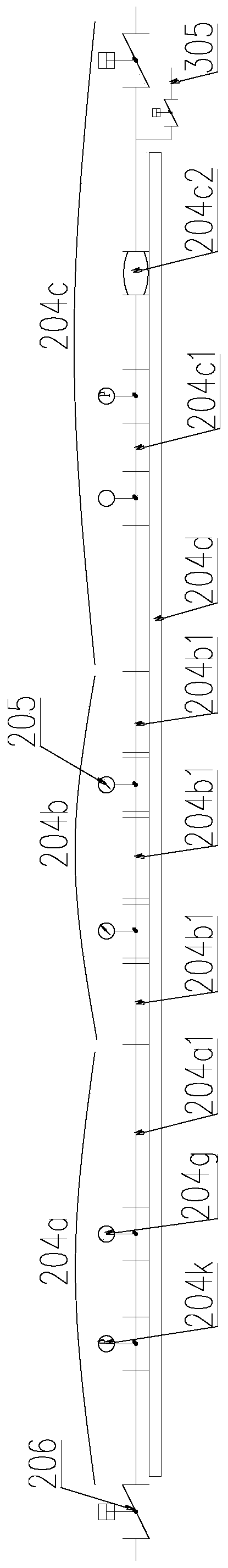

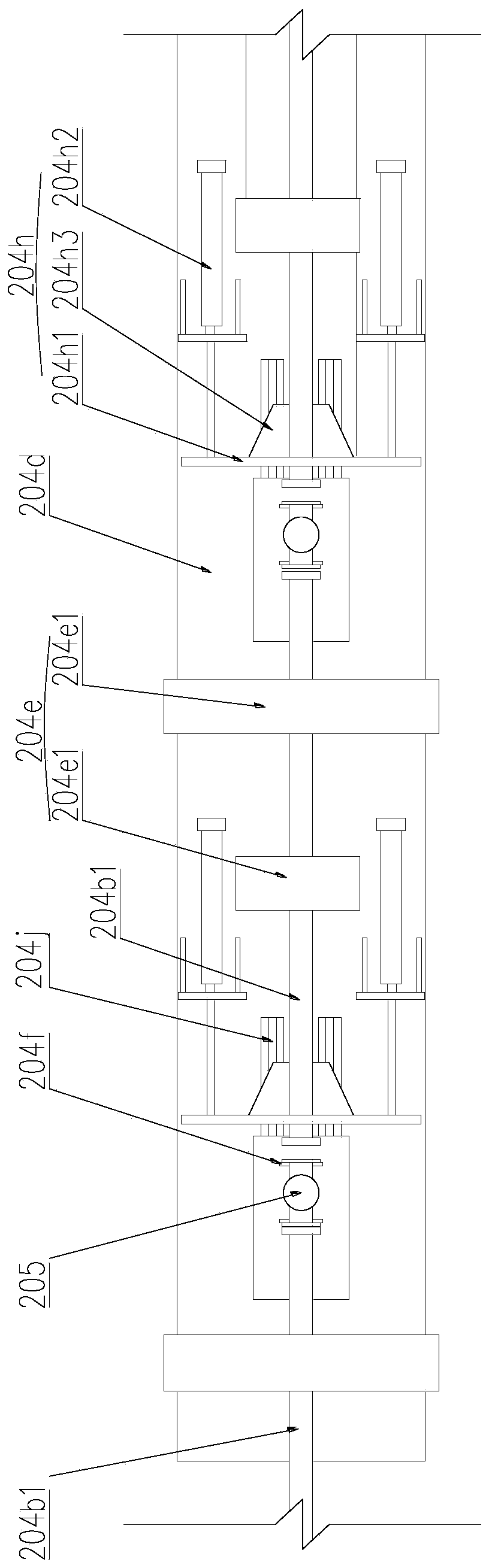

[0052] The calibration mechanism 2 includes P standard tubes 201 connected in parallel. P is an integer greater than or equal to 2. The water inlet ends of all standard tubes 201 are connected to the surge tank 105, and the standard tube 201 is equipped with a standard tube control Valve 201 and standard flow meter 203. The water outlet ends of all standard pipes 201 are connected to the same first manifold 211. The first manifold 211 is connected to at least two calibration tubes 204, and...

Embodiment 2

[0069] Embodiment 2, a calibration method based on embodiment 1, is carried out in the following steps:

[0070] S1 Set calibration line: select any one of the calibration tubes 204 as the line to be calibrated, open the calibration tube control valve 206 on the selected calibration tube 204 to make it in the path state, and close the other calibration tube control valves 206 , The flow meter to be checked 205 has i flow to be calibrated, denoted as Q i ,i=1,2,3...n 1 , Choose any Q i For calibration, there are generally 4 flows to be checked, which are Q 1 Minimum flow, Q 2 Boundary flow, Q 3 Common flow, Q 4 Overload flow, all flow units are m 3 / h;

[0071] S2 Select the water supply mode: Count the maximum water supply flow Q of the K first water supply pipes 104 connected to the water supply pipe 108 KP

[0072]

[0073] Among them, Q pupm,p -Pump flow of water pump, m 3 / h;

[0074] If Q KP ≥Q i , Then open the water supply control valve 109, the second water supply switch 111...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com