Concrete-filled steel tubular column compactness testing tool

A technology for detecting the density of concrete filled steel tube columns, which is applied to measuring devices, instruments, and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., to achieve the effects of avoiding potential safety hazards and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

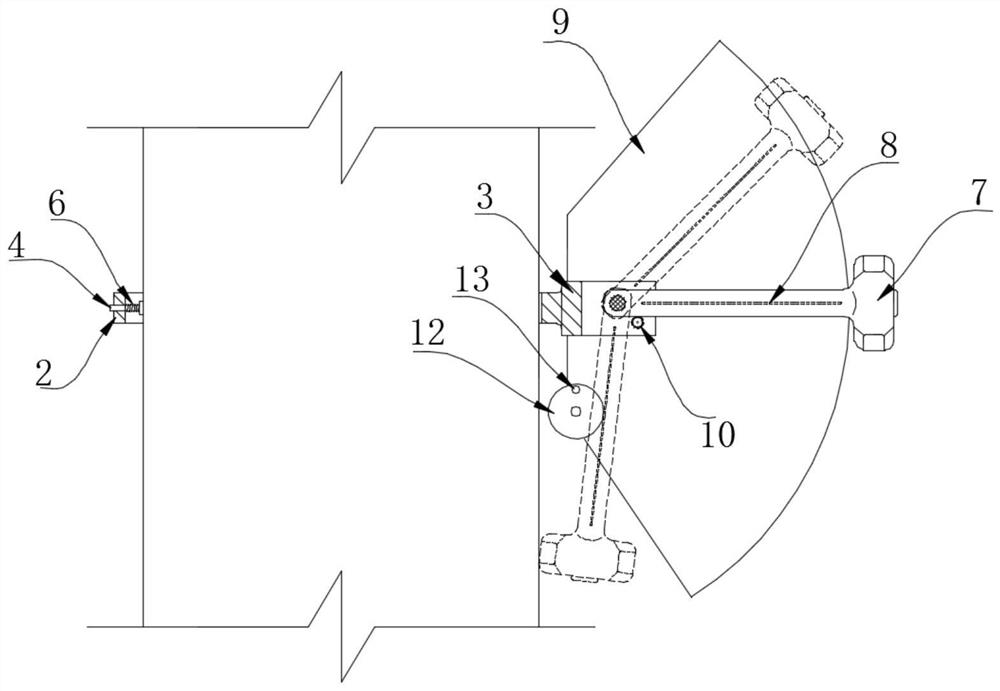

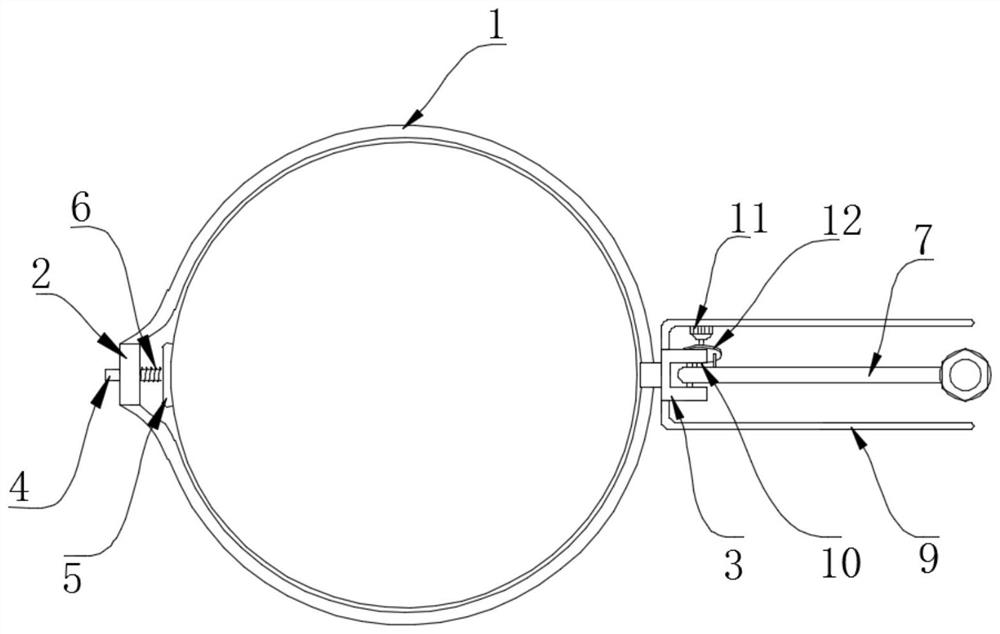

[0029] refer to Figures 1 to 5 , Concrete-filled steel tubular column compactness detection tool, a fixing ring 1 set on the concrete column, a tensioning frame 2 and a U-shaped fixing frame 3 are fixed on the fixing ring 1, and a tensioning assembly is arranged on the tensioning frame 2 , the fixing frame 3 is provided with a height-fixing component; the fixing frame 3 is provided with two opposite and parallel permanent magnet plates 9, and a sound test hammer 7 is connected in the fixing frame 3 using a pin shaft to rotate;

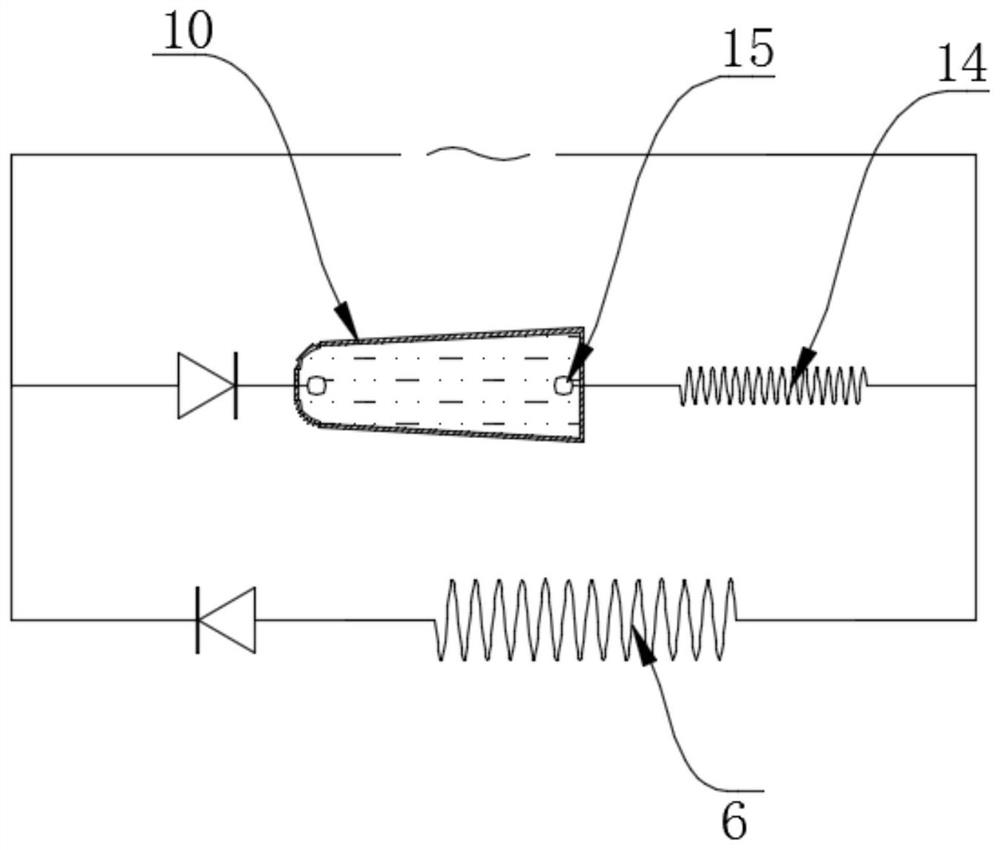

[0030] The tensioning assembly includes a sliding rod 4 that is slidably connected to the tensioning frame 2, a stop block 5 is fixed at one end of the sliding rod 4 close to the concrete column, and a metal spring 6 is sleeved on the sliding rod 4;

[0031] The height-fixing component includes a soft bag column 10 embedded in the side wall of the U-shaped groove of the fixing frame 3, the soft bag column 10 is a hollow bag-shaped structure made of ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com