Motor rotor and synchronous reluctance motor

A technology of motor rotor and rotor core, which is applied to synchronous motors, electrical components, electromechanical devices, etc. for single-phase current, can solve the problem of weakening the amplitude of the air gap magnetic density, the decrease of motor output torque, and the operation performance of the motor. It can optimize the air gap magnetic density, improve the salient pole ratio, and increase the stator and rotor air gap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

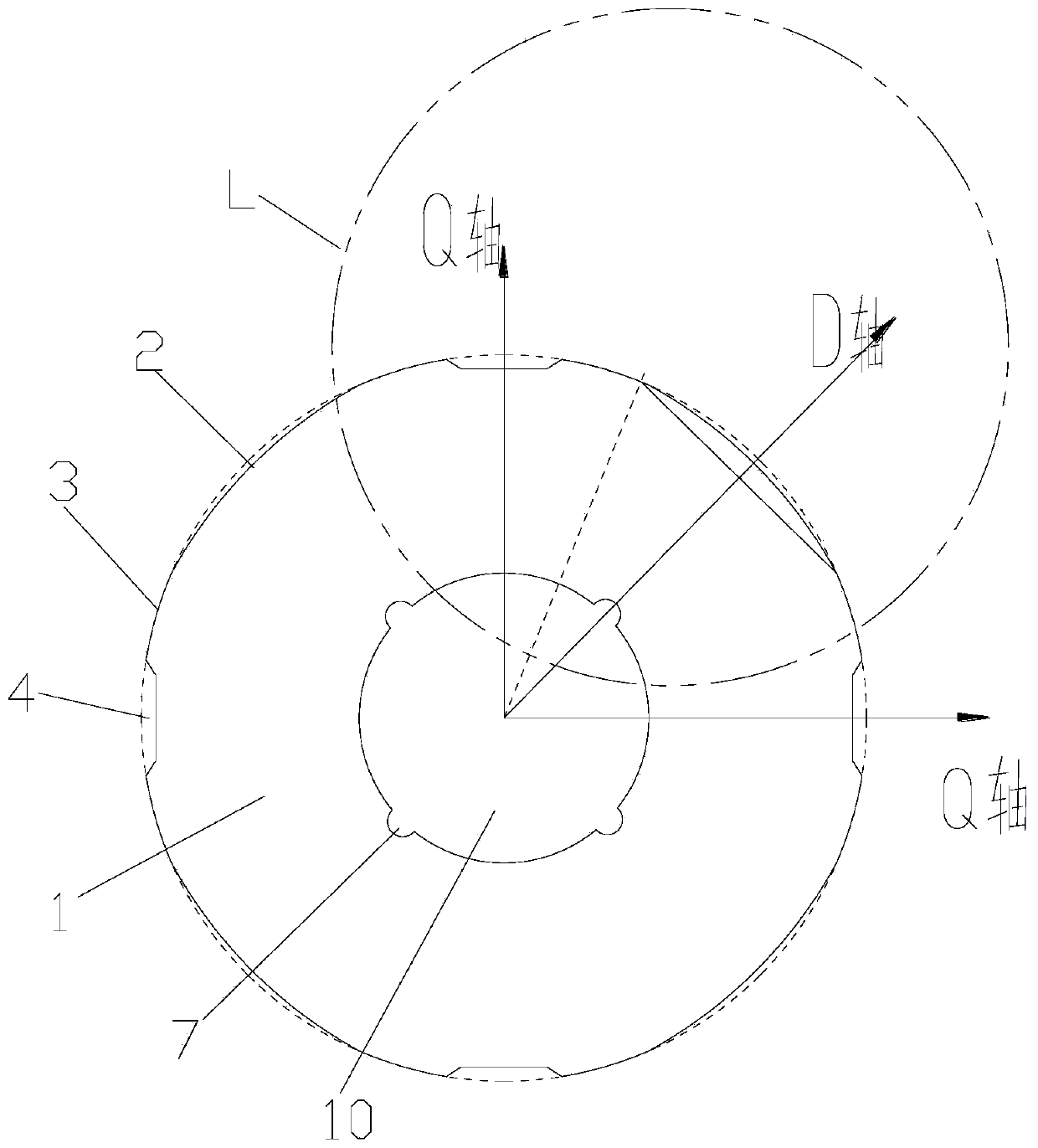

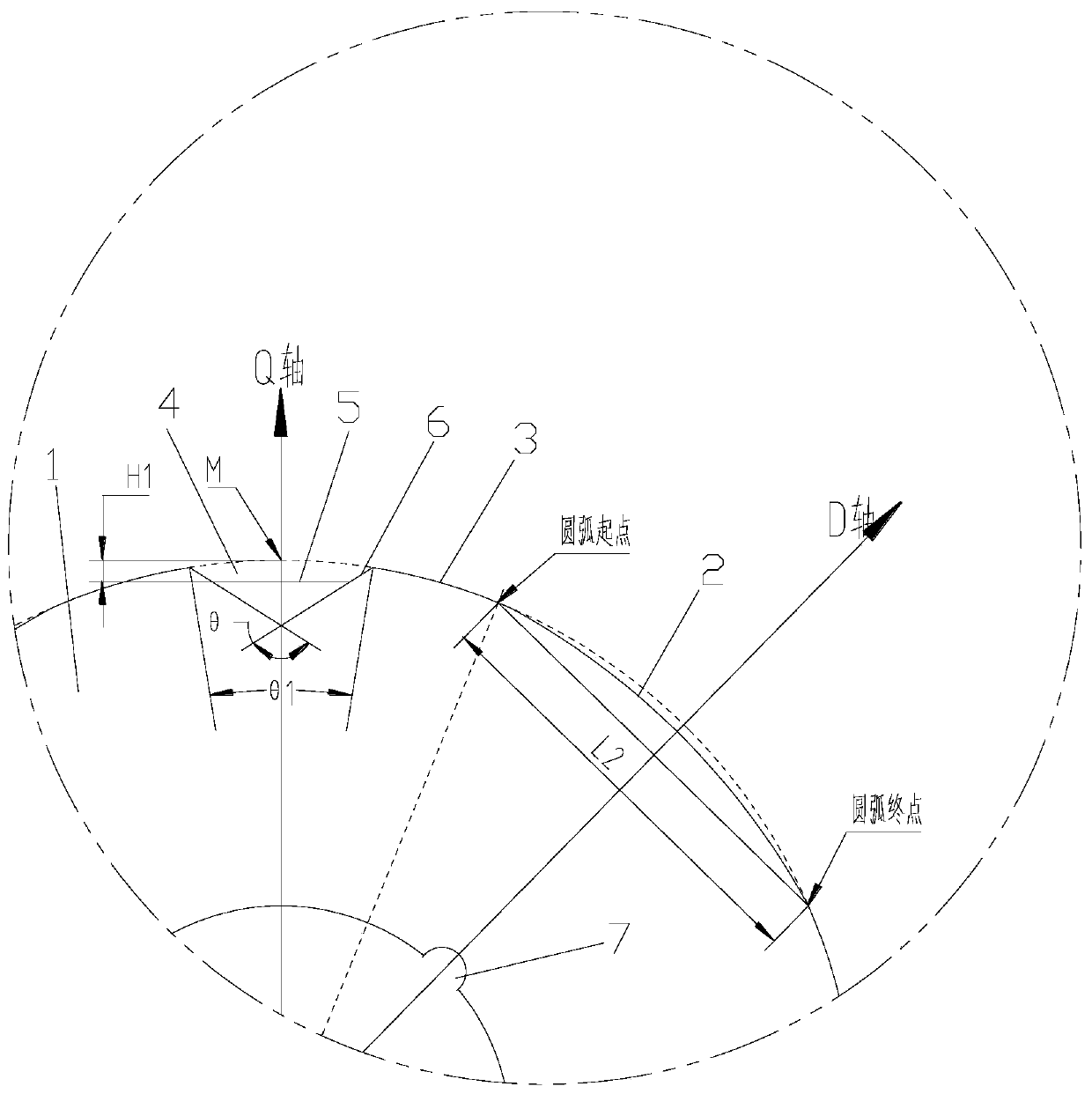

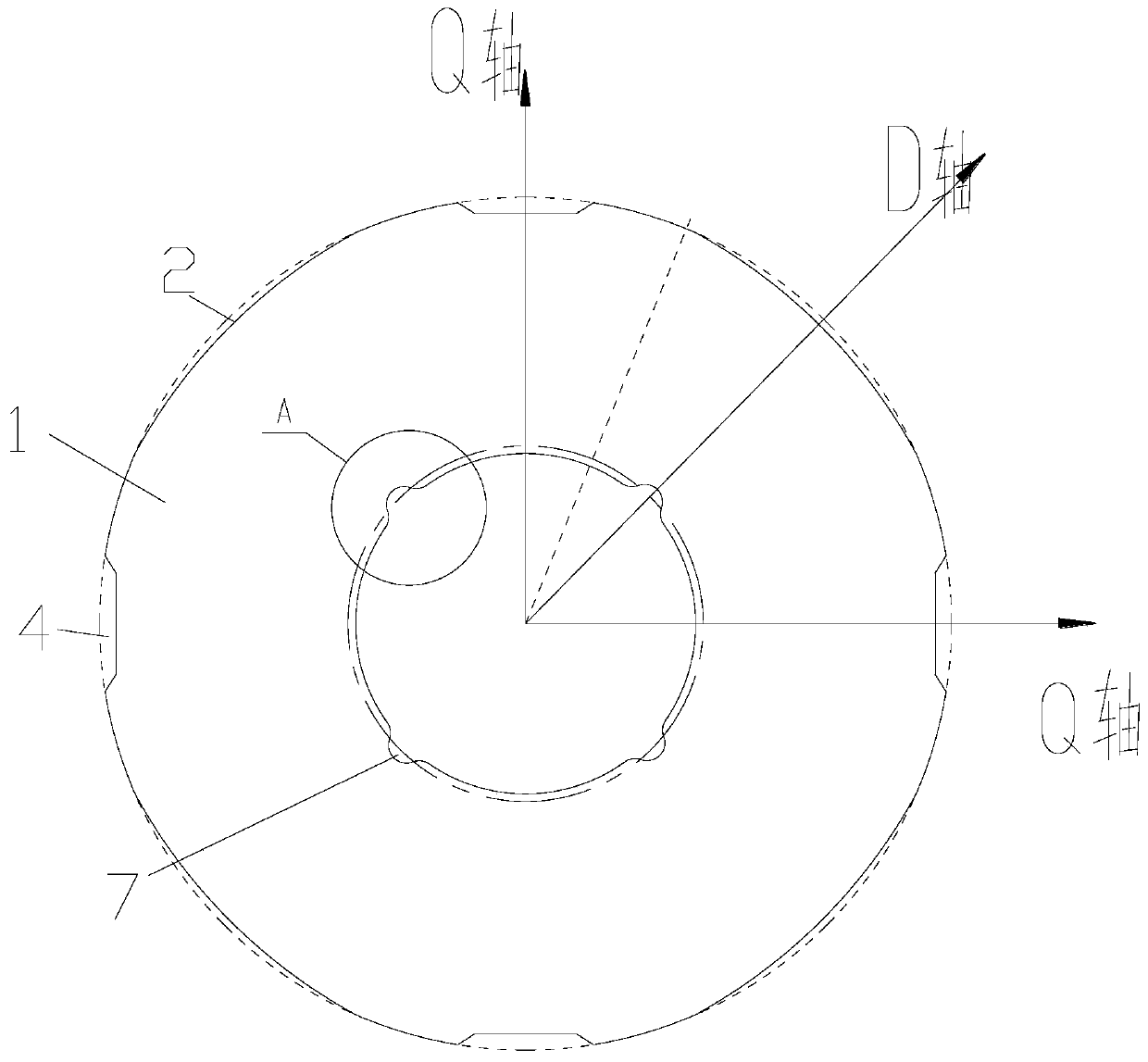

[0029] see in conjunction Figure 1 to Figure 8 As shown, according to the embodiment of the present application, the motor rotor includes a rotor core 1. On a section perpendicular to the central axis of the rotor core 1, the outer peripheral side of the rotor core 1 has an inwardly deflected arc 2, and the inwardly deflected arc 2 is located on the D axis, and the inward arc 2 is located between the largest outer circle 3 of the rotor core 1 and the chord of the inward arc 2 .

[0030] The motor rotor of the present application adopts an inwardly deflected circular arc structure on the outer circumference of the rotor core 1 located on the D axis, which can increase the stator-rotor air gap, optimize the air gap flux density in the D-axis direction, and effectively improve the synchronous reluctance motor in operation. The saliency ratio in the process increases the electromagnetic torque, and at the same time, it can avoid the air gap being too large and weaken the amplitud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com