Coolant heater

A coolant and heater technology, applied in water heaters, fluid heaters, heating/cooling equipment, etc., can solve the problems of incomplete overheating prevention function of heating elements, easily damaged heating elements, fire and other problems, so as to improve overheating Effects of sensing responsiveness, reduction of failure factors, and prevention of overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Hereinafter, the coolant heater according to the present invention having the above configuration will be described in detail with reference to the accompanying drawings.

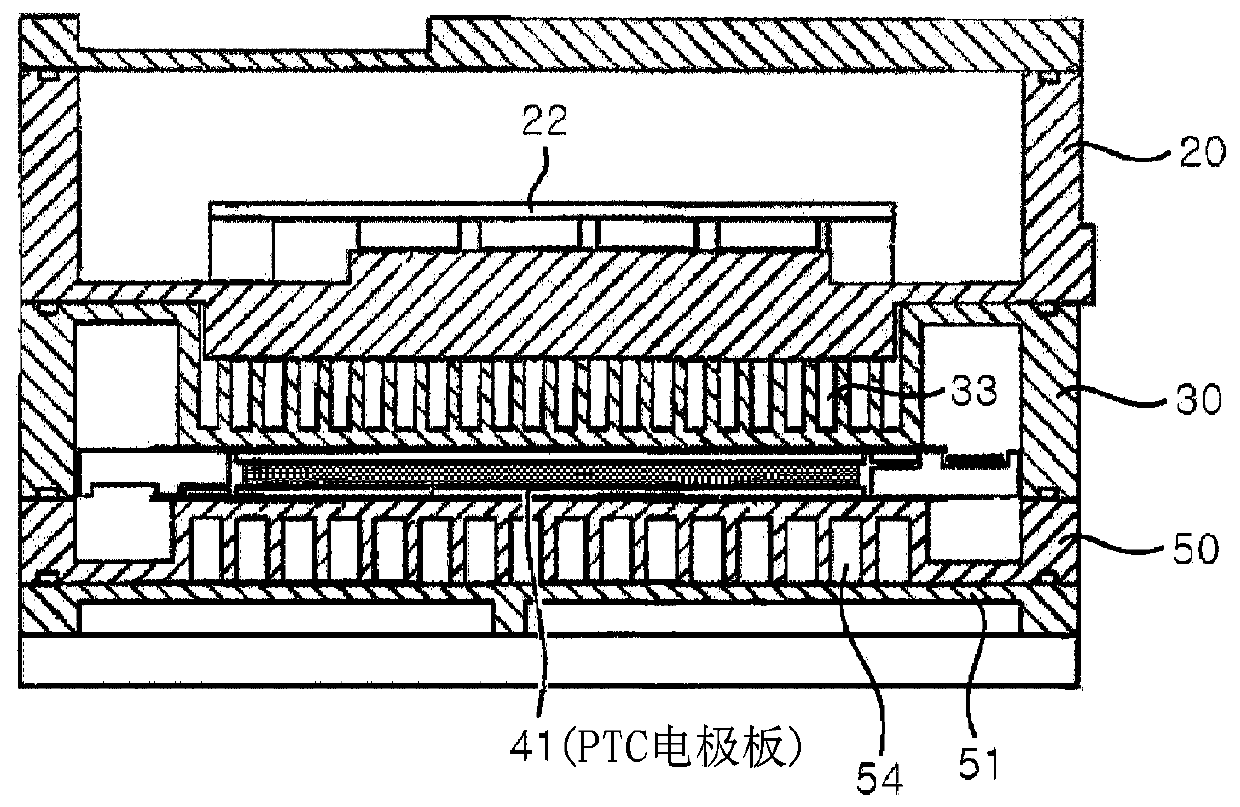

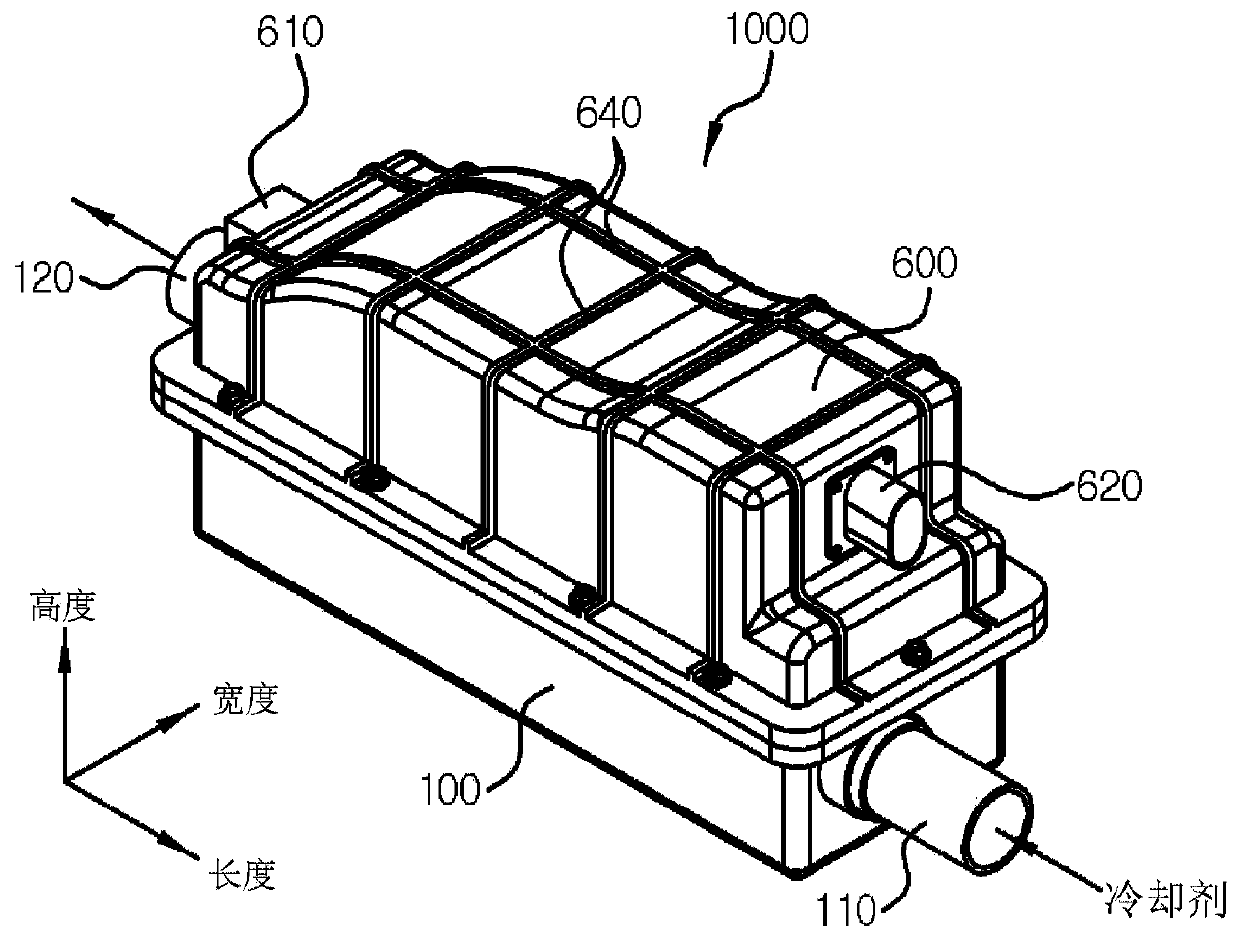

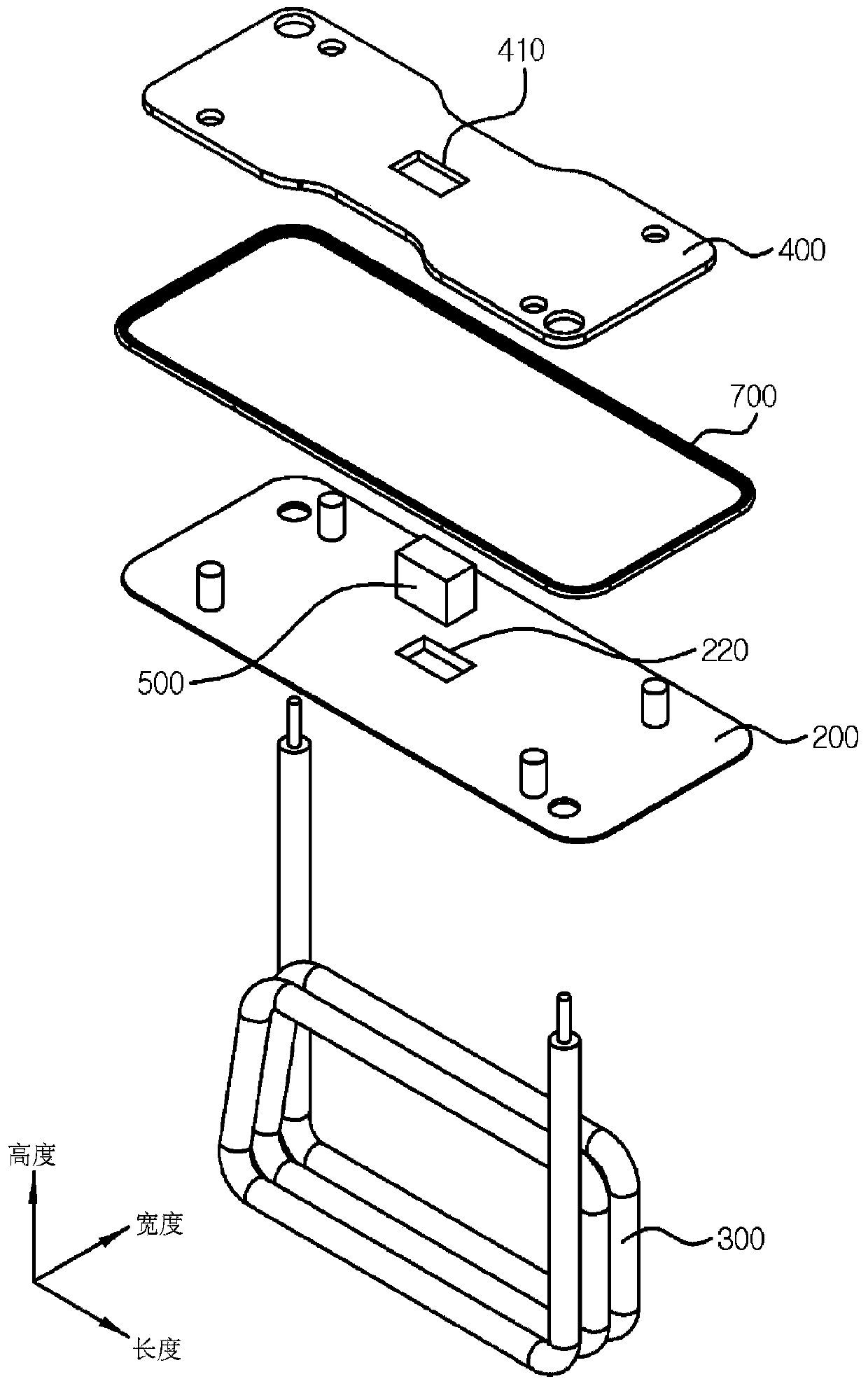

[0051] figure 2 is an assembled perspective view showing the coolant heater according to the first exemplary embodiment of the present invention, image 3 is a partially exploded perspective view showing the coolant heater according to the first exemplary embodiment of the present invention; and Figure 4 and Figure 5 are a side sectional view and a front sectional view showing the coolant heater according to the first exemplary embodiment of the present invention.

[0052] As shown therein, the coolant heater 1000 according to the first exemplary embodiment of the present invention may include: a first housing 100 formed in a concave container shape with an open upper side and including a The inlet 110 of the coolant and the outlet 120 for discharging the coolant; the cover plate 200, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com