Pressure cooking appliance and control method of pressure cooking appliance

A technology of cooking utensils and pressure, applied in the direction of pressure cookers, cooking utensils, household appliances, etc., can solve the problems of spraying, unable to open immediately, and long natural cooling time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

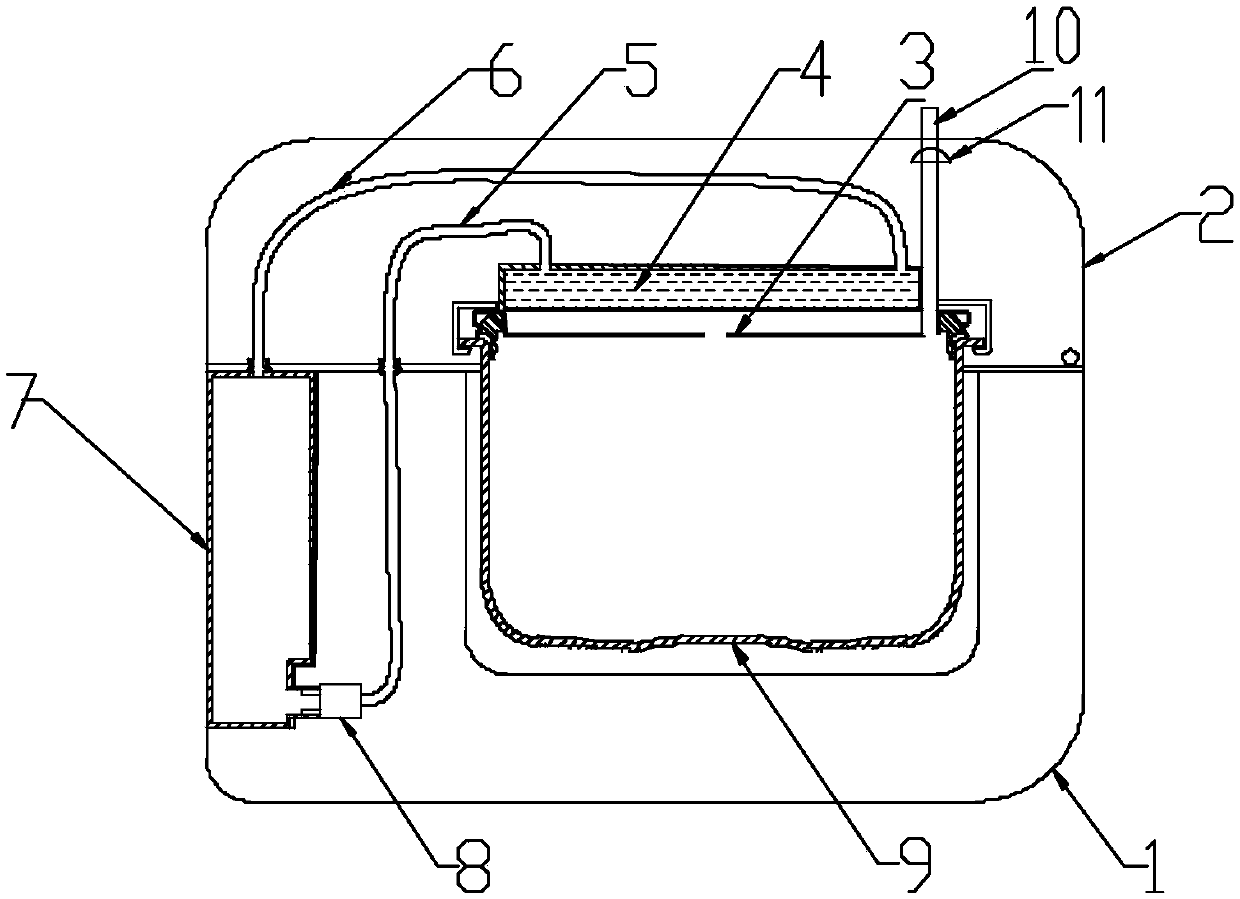

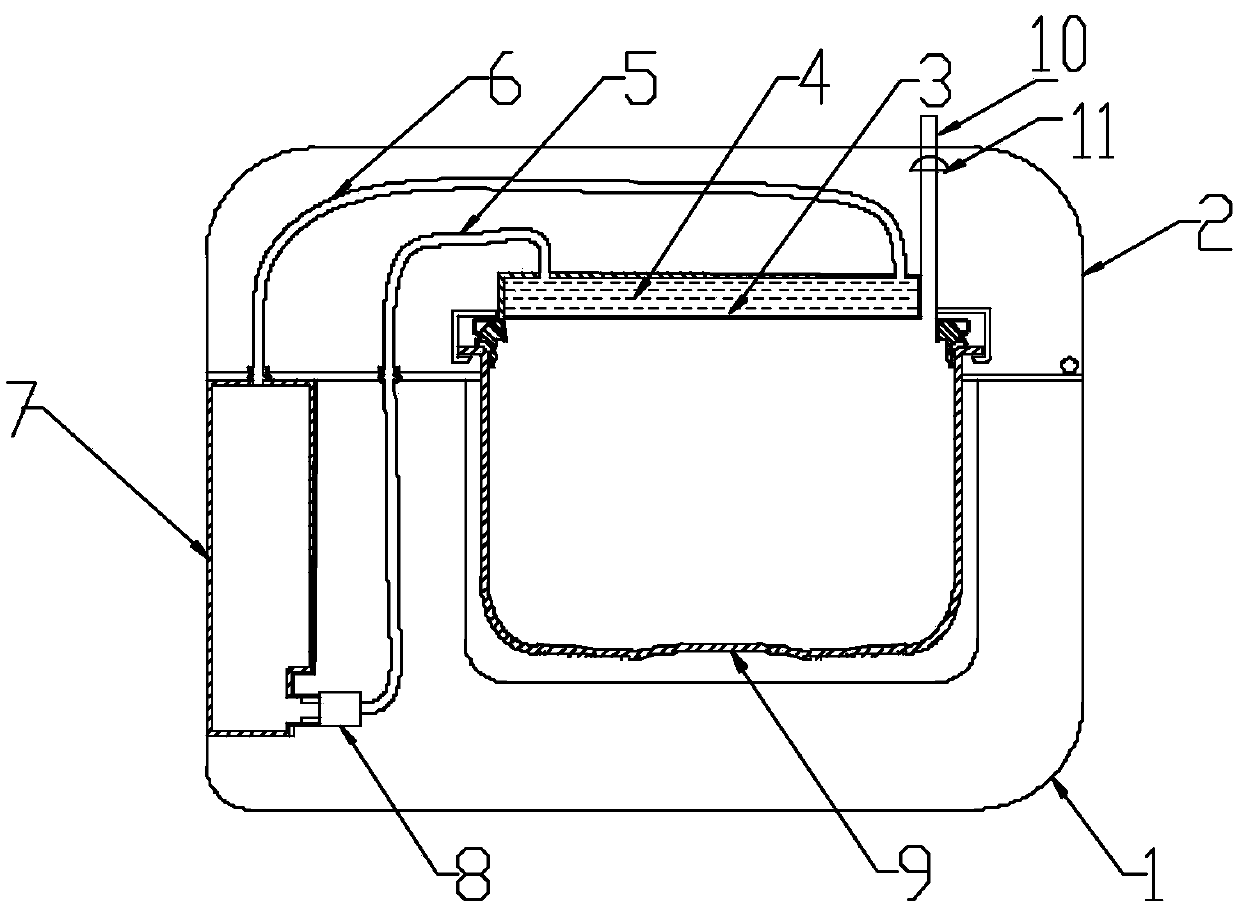

[0017] see figure 1 , which shows the structure of a pressure cooking appliance provided by an embodiment of the present invention, the pressure cooking appliance may include a pot body 1, an upper cover 2 and a cover plate 3; the upper cover and the cover plate form a pot cover; the The pot body 1 is provided with an inner container 9, which forms a cooking cavity with the upper cover 2; wherein, the cover plate 3 is provided with a cooling device 4, and the cooling device 4 is directly in contact with the cooking cavity, so The cooling device 4 is filled with liquid for heat exchange with the cooking cavity;

[0018] The pressure cooking appliance also includes an exhaust device, including: an exhaust passage 10 provided on the pot cover and communicating with the interior of the inner pot, and a pressure limiting valve 11 for controlling the opening and closing of the exhaust passage;

[0019] The pressure cooking appliance further includes a control part configured to use...

Embodiment 2

[0047] Based on the same technical concept as the foregoing embodiments, the embodiments of the present invention provide a control method flow based on the pressure cooking appliance involved in the foregoing embodiments, see image 3 , which can include:

[0048] S301: Use the cooling device and the exhaust device to reduce the pressure in the cooking cavity based on a set pressure reduction strategy.

[0049] For pressure cookers such as figure 1 or figure 2 As shown, the cooling device also includes a water inlet and a water outlet, and the pot body is also provided with a driving water pump and a water tank containing the liquid; the water inlet is connected with the water outlet of the water tank through a water supply pipe, so The water outlet is connected to the water return port of the water tank through the water return pipe to form a circulation loop; the driving water pump is used to drive the liquid in the water tank to circulate in the circulation loop;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com