Epoxy resin curing furnace

A technology of epoxy resin curing and curing table, which is applied in the field of curing furnace, can solve the problems of increased machine operation noise, unstable force, resonance and noise, etc., and achieve the goals of reducing fan shaking, stable output air volume and improving stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described below in conjunction with accompanying drawing.

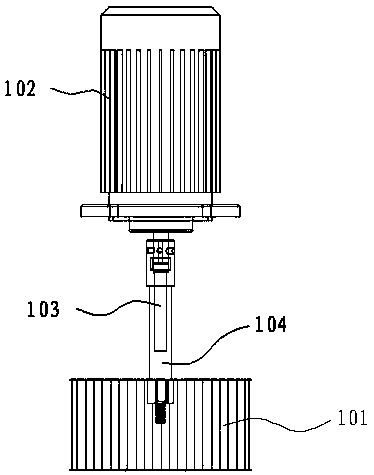

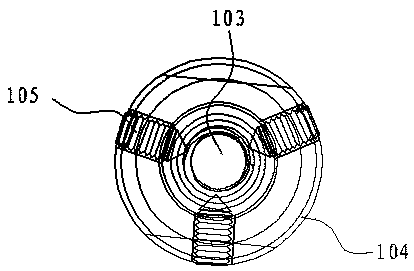

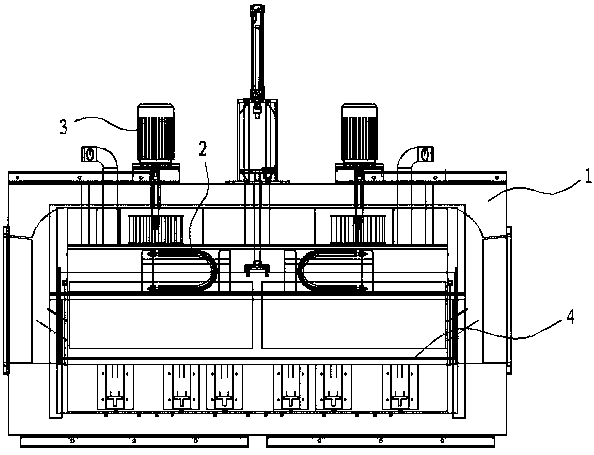

[0017] As shown in Figures 3 to 5, an epoxy resin curing furnace according to the present invention includes a box body 1, a heating pipe 2, a centrifugal fan 3 and a curing table 4 for carrying workpieces. The heating pipe 2 is located on the curing table 4 Above, the centrifugal fan 3 is located above the heating pipe 2, the impeller shaft 5 of the centrifugal fan 3 is connected to the motor output shaft 6, and two keyways 8 are symmetrically arranged near the end of the motor output shaft 6, so that The impeller shaft 5 is correspondingly provided with two symmetrically distributed protruding keys 7 , and the impeller shaft 5 and the motor output shaft 6 are plug-fitted and connected with corresponding key grooves 8 through the protruding keys 7 .

[0018] As shown in Figures 4 and 5, the convex key 7 and the keyway 8 are arranged in equal parts of 180° in the radial direction, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com