Negative dielectric anisotropic liquid crystal composition, liquid crystal display element and liquid crystal display

一种液晶组合物、各向异性的技术,应用在液晶材料、仪器、非线性光学等方向,能够解决降低旋转粘度、响应时间慢等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0084] The preparation method of liquid crystal medium comprises the following steps:

[0085] (1) Arrange the monomers used in order;

[0086](2) Place the stainless steel beaker on the balance, and put the monomer into the stainless steel beaker with a spoon;

[0087] (3) Add monomer liquid crystals by required weight in turn;

[0088] (4) Place the stainless steel beaker with the added material on the magnetic stirring apparatus to heat and melt;

[0089] (5) After most of the mixture in the stainless steel beaker is melted, add a magnetic rotor into the stainless steel beaker, stir the liquid crystal mixture evenly, and obtain the liquid crystal medium after cooling to room temperature.

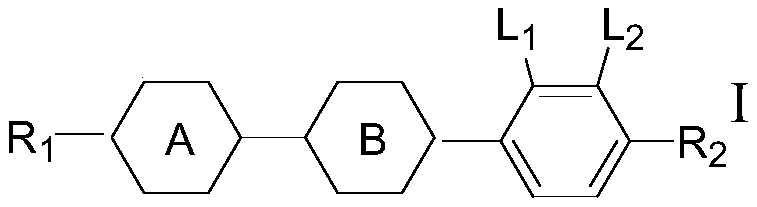

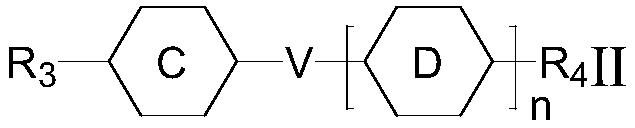

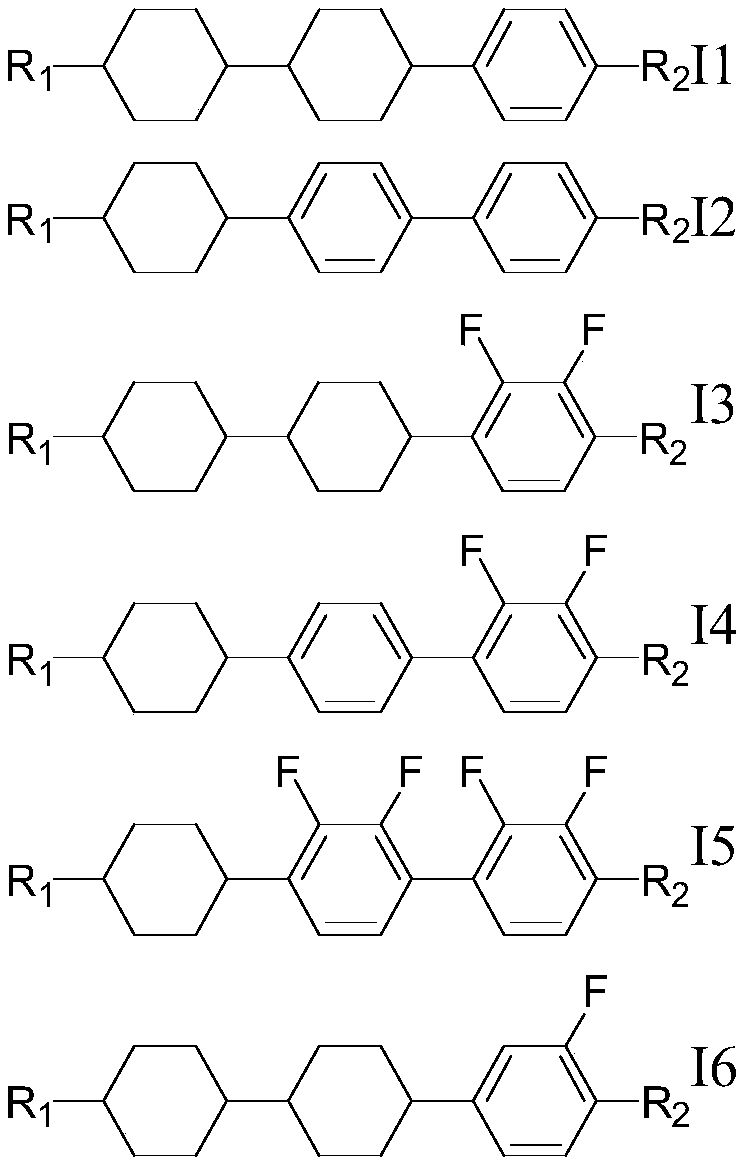

[0090] The structure of the liquid crystal monomer in the embodiment of the present invention is represented by a code, and the code representation methods of the liquid crystal ring structure, terminal group, and linking group are shown in Table 1 and Table 2 below.

[0091] Table 1 C...

Embodiment 1

[0100] The formula and corresponding properties of the liquid crystal composition are shown in Table 3 below.

[0101] Table 3 The formula and corresponding performance of the liquid crystal composition of embodiment 1

[0102]

[0103] The content of each liquid crystal compound in Example 1 is calculated based on the total content of the compounds represented by Formula I, Formula III, Formula IV, and Formula V in the liquid crystal composition of Example 1 as 100%.

Embodiment 2

[0105] The formula and corresponding properties of the liquid crystal composition are shown in Table 4 below.

[0106] Formulation and corresponding performance of the liquid crystal composition of table 4 embodiment 2

[0107]

[0108] The content of each liquid crystal compound in Example 2 is calculated based on the total content of the compounds represented by Formula I and Formula III in the liquid crystal composition of Example 2 as 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com