Puncture exfoliation test puncture outfit, device and method

A test device and puncture technology, which is applied in the testing of measuring devices, instruments, and mechanical parts, etc., can solve the problems of loss, the insertion depth of the puncture device cannot be kept consistent, and the test accuracy is affected, so as to achieve a constant water injection volume and prevent test failure. , the effect of improving the test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

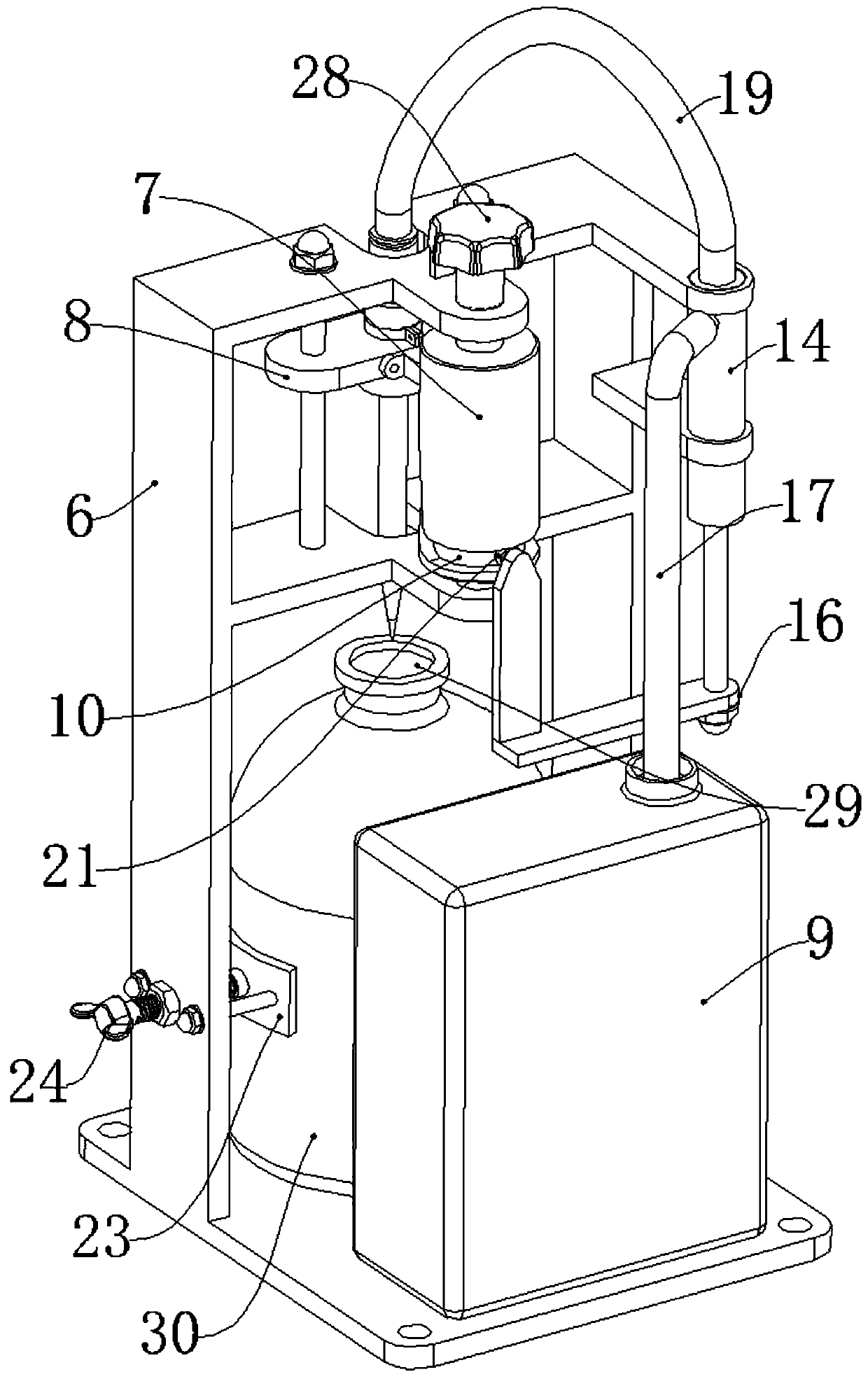

[0051] Such as Figure 1-Figure 15 As shown, a puncture falling chip test device includes a main bracket 6, a cylindrical cam 7, a puncture device, a puncture device support 8, a syringe, a water tank 9, a clamp and a damping mechanism.

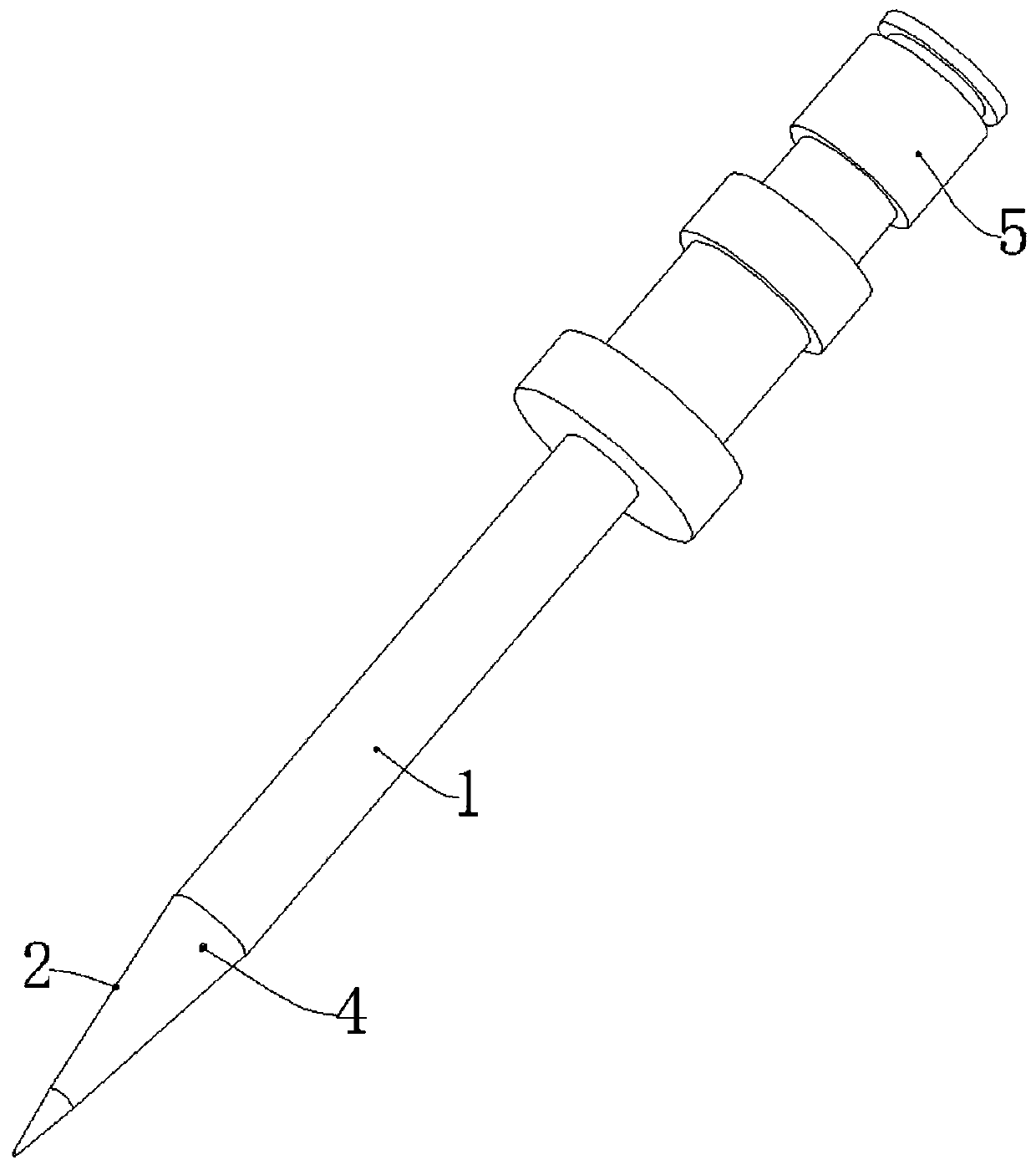

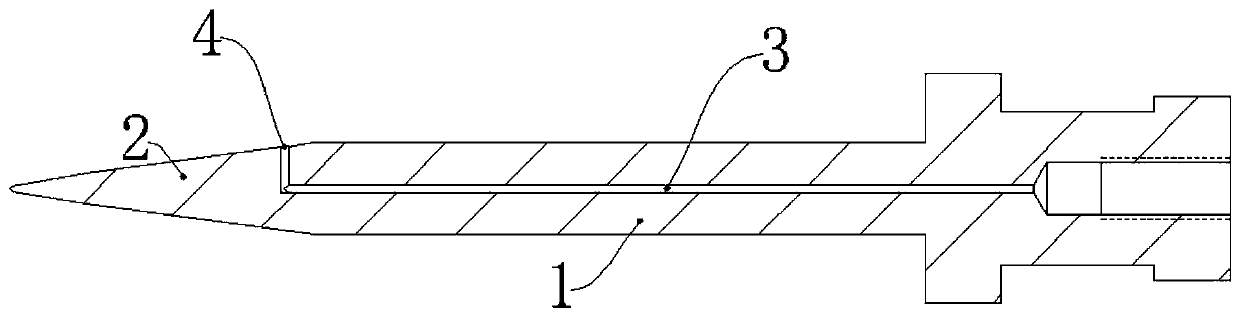

[0052] Such as figure 1 and figure 2 As shown, the puncture device includes a needle body 1 and a quick intubation connector 5. One end of the needle body 1 is provided with a conical needle 2, and the needle body 1 is provided with a water injection channel 3. The water injection channel 3 is machined by electric discharge. A water outlet 4 is provided on the conical surface, and the water outlet 4 communicates with the water injection channel 3 . The quick intubation connector 5 is threadedly connected with the needle body 1 and is communicated with the water injection channel 3, and is used for quick connection with the pipeline.

[0053] If the diameter of the water outlet 4 is too large, the circumference of the incision formed on th...

Embodiment 2

[0070] Such as Figure 16 and 17 As shown, the trocar in this embodiment includes a needle body 1 and a quick intubation connector 5. One end of the needle body 1 is provided with a conical needle 2, and a water injection channel 3 is provided inside the needle body 1, which is different from the first embodiment. Four water outlets 4 are provided on the conical surface of the needle 2 and are evenly spaced along the circumference of the needle 2 . The water outlets 4 communicate with the water injection channel 3 . The water injected into the water injection channel 3 flows out along a plurality of evenly distributed water outlets 4, the coverage area of the water flow is relatively large, and the flushing effect on the falling debris is good.

Embodiment 3

[0072] Such as Figure 18 As shown, the trocar in this embodiment includes a needle body 1 and a quick intubation connector 5. One end of the needle body 1 is provided with a conical needle 2, and a water injection channel 3 is provided inside the needle body 1, which is different from the first embodiment. The water outlet 4 is arranged on the outer circular surface of the needle body 1 , and the water outlet 4 communicates with the water injection channel 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com