Dryness regulated integrated heat exchanger test system

A comprehensive testing and heat exchanger technology, applied in the testing of machines/structural components, instruments, measuring devices, etc., can solve the problem of the narrow test flow adjustment range of the test system, and achieve the expansion of the test condition range, low energy consumption, Overcome the effect of single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

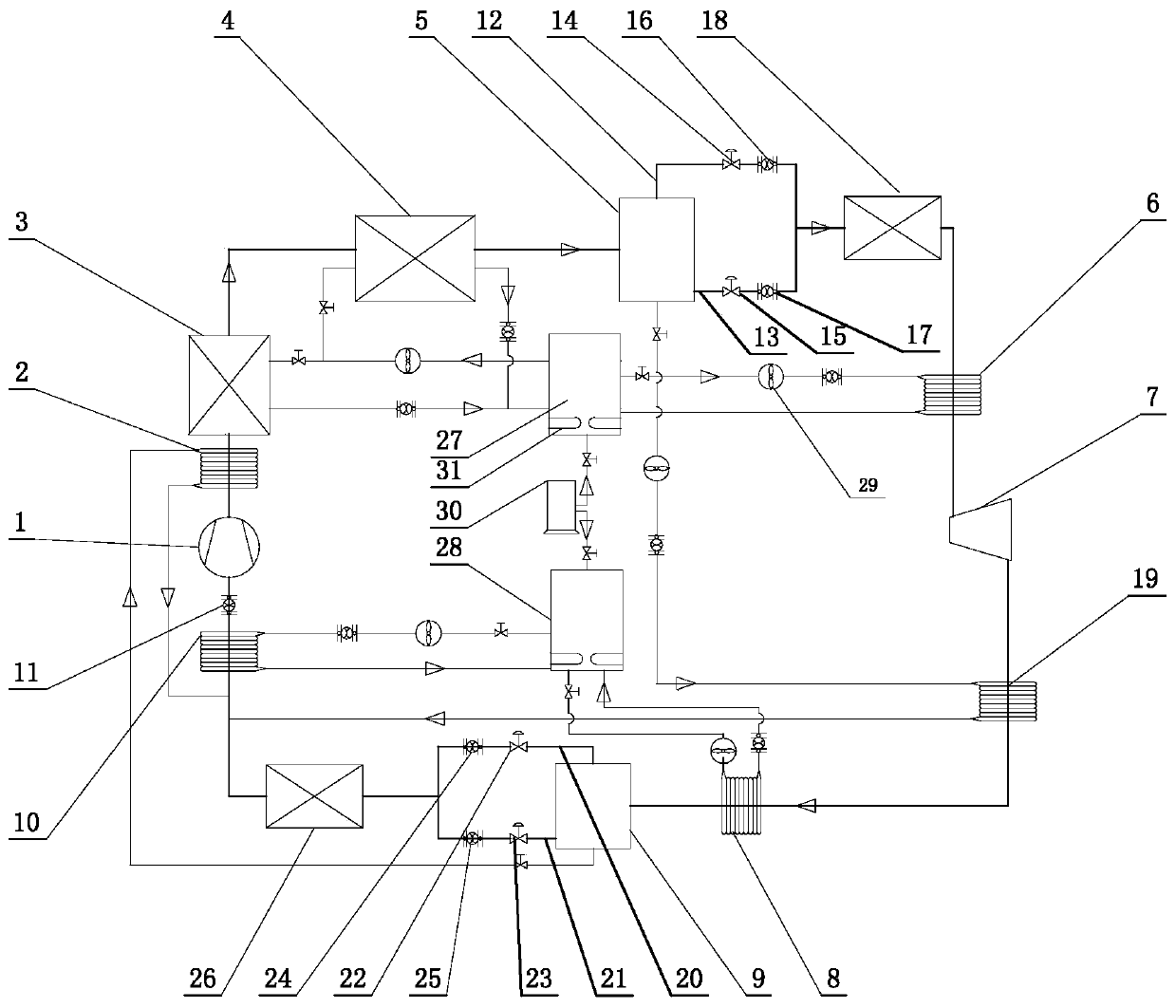

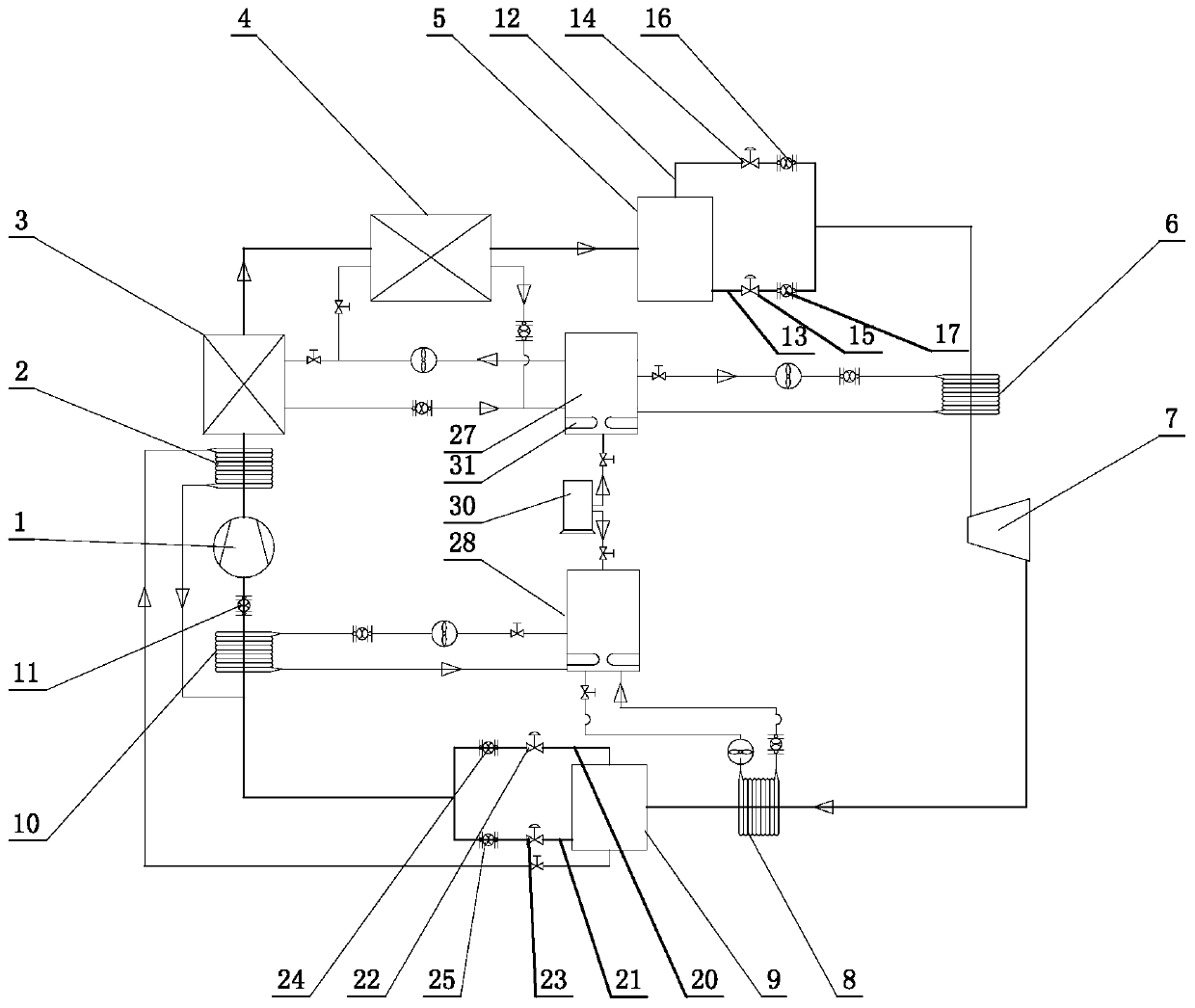

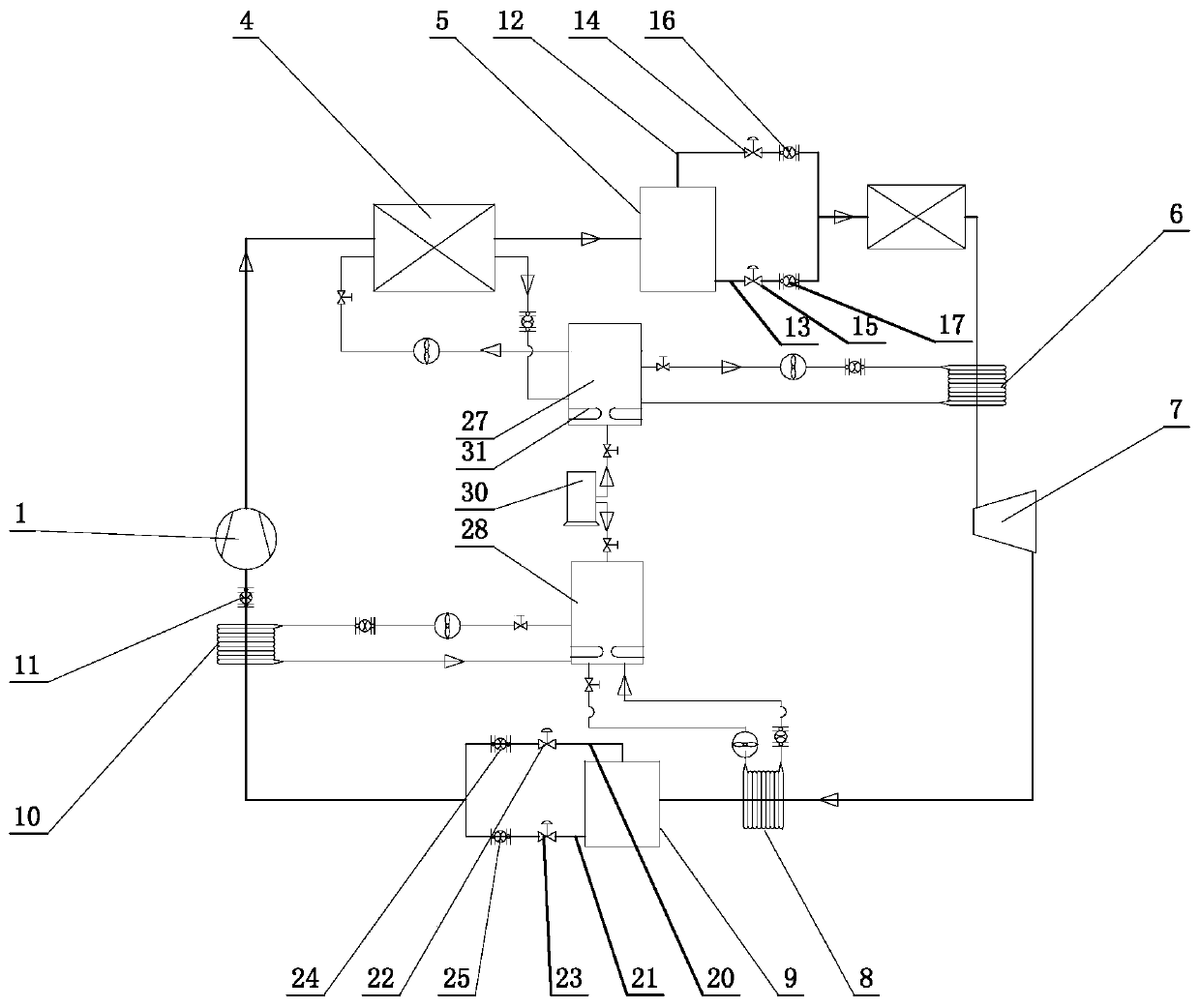

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0030] see figure 1 , a dryness deployment type heat exchanger comprehensive testing system, including an organic Rankine cycle device and a water cycle device, the water cycle device includes a water pump 29 and a water tank, and is characterized in that the organic Rankine cycle device includes a heat exchanger test cycle assembly, an evaporator The test cycle assembly and the condenser test cycle assembly; wherein, the heat exchanger test cycle assembly, the evaporator test cycle assembly and the condenser test cycle assembly are provided with regulating valves, by controlling the opening or closing of the regulating valve valve, and controlling Operation of heat exchanger test cycle components, evaporator test cycle components and condenser test cycle components so that any one of the test cycle components can be operated alone, or any two test cycl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com