Technology for degrading perchlorate in water and used degradable composite material

A technology of composite materials and parameters, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of inability to achieve effective removal, inconsistent removal rate, low removal rate, etc., to achieve The effect of overcoming the decline in the metabolic function of perchlorate-reducing bacteria, easy automatic control, and moderate degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A kind of technology that biodegradable material is used as carbon source to remove perchlorate in water, concrete steps are as follows:

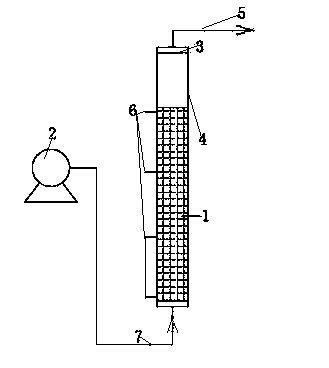

[0058] In this example, the sludge domesticated by perchlorate from Jinan No. An appropriate amount of sodium perchlorate (concentration 2mg / L) was added to the groundwater in the southern mountainous area of the city as influent water, and the influent flow rate was 50mL / h into the column reactor. The column reactor height was 40cm, the particle filling height was 30cm, and the inner diameter was 3cm. When the perchlorate groundwater flows through the reactor, it can fully contact the biofilm on the composite particles, and degrade perchlorate with the small molecule organic matter released by the microbial degradation carrier particles as the carbon source, and collect the treated water after 4 hours.

[0059] The preparation methods of the degradable composite material particles are respectively as follows:

[0060] Weigh 50g o...

Embodiment 2

[0067] A kind of technology that biodegradable material is used as carbon source to remove perchlorate in water, concrete steps are as follows:

[0068] In this example, the sludge domesticated by perchlorate from Jinan No. An appropriate amount of sodium perchlorate (concentration 4mg / L) was added to the groundwater in the southern mountainous area of the city as influent water, and the influent flow rate was 80mL / h into the column reactor. The column reactor height was 60cm, the particle filling height was 40cm, and the inner diameter was 3cm. When the perchlorate groundwater flows through the reactor, it can fully contact the biofilm on the composite particles, and use the small molecular organic matter released by the microbial degradation carrier particles as the carbon source to degrade perchlorate, and collect the treated water after 6 hours.

[0069] The preparation method of the degradable composite material particles is as follows:

[0070] Weigh 30g of PHB and 60...

Embodiment 3

[0073] A kind of technology that biodegradable material is used as carbon source to remove perchlorate in water, concrete steps are as follows:

[0074] In this example, the sludge domesticated by perchlorate from Jinan No. An appropriate amount of sodium perchlorate (concentration 4mg / L) was added to the groundwater in the southern mountainous area of the city as influent water, and the influent flow rate was 80mL / h into the column reactor. The column reactor height was 60cm, the particle filling height was 40cm, and the inner diameter was 3cm. The perchlorate groundwater flows through the reactor, which can fully contact the biofilm on the composite particles, and use the small molecular organic matter released by the microbial degradation carrier particles as the carbon source to degrade perchlorate, and collect the treated water after 4 hours.

[0075] The preparation method of the degradable composite material particles is as follows:

[0076] Weigh 50g of PHB and 30g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com