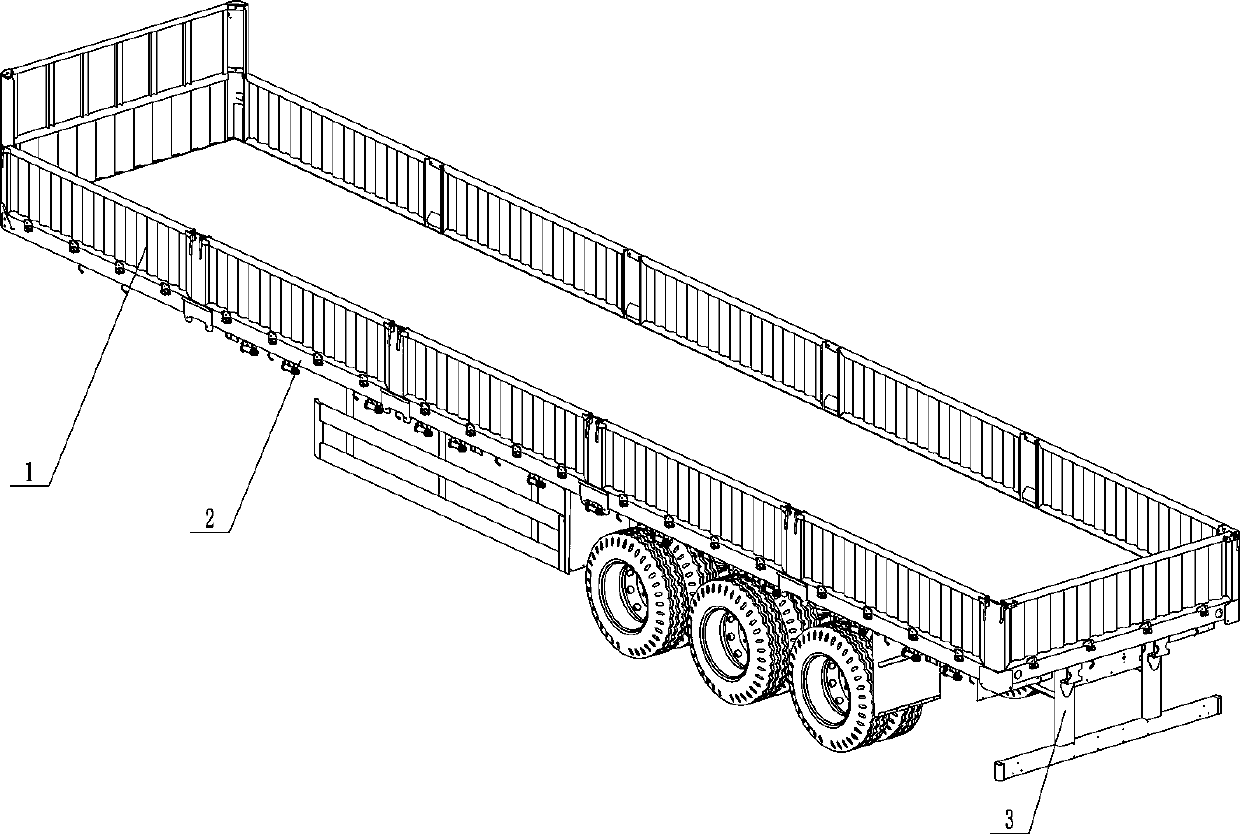

Assembled semi-trailer rear protection net structure and assembling method

A rear protection and semi-trailer technology, which is applied to vehicle components, transportation and packaging, vehicle safety arrangements, etc., can solve problems such as damage, low efficiency, and rear protection falling off, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

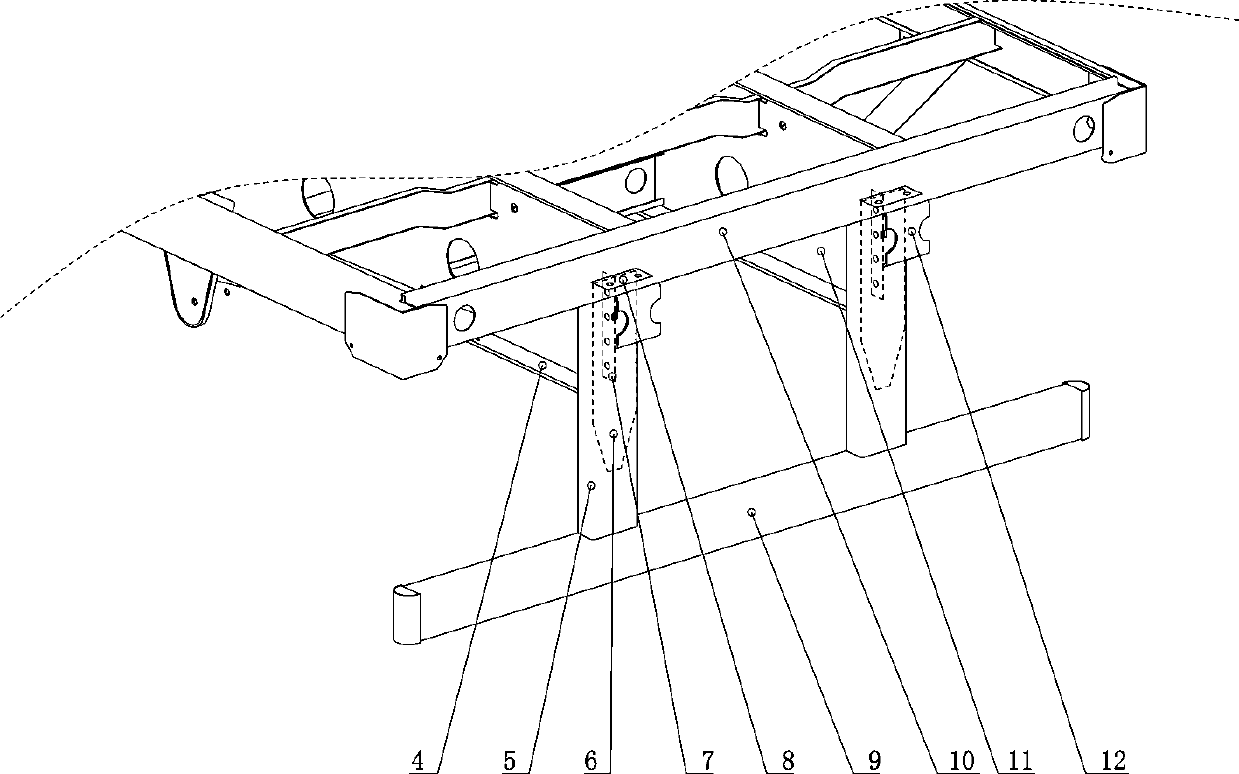

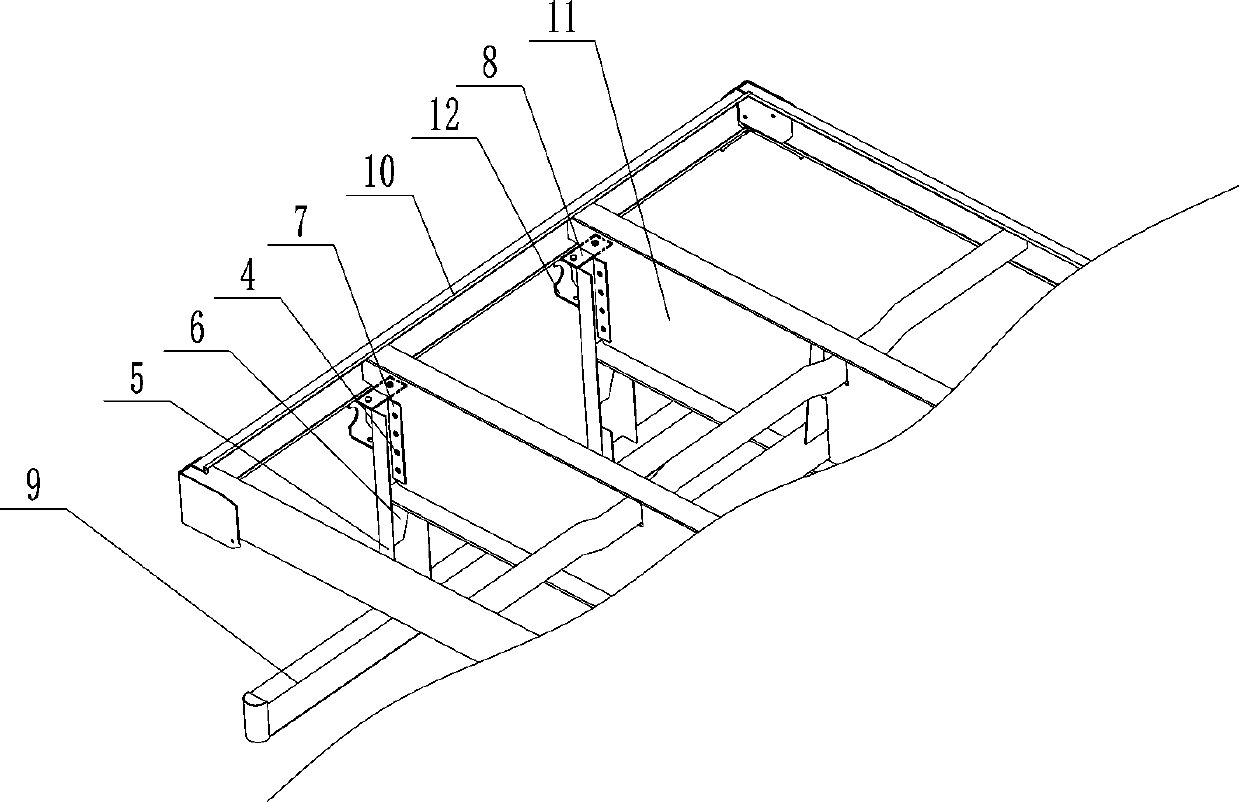

[0036] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

[0037] Such as Figure 1-Figure 9 As shown, an assembled semi-trailer rear protective net structure includes a rear protective cross brace 9, two rear protective vertical braces 5, a vertical brace reinforcement plate 6 and a web connecting plate 7, and the bottom ends of each rear protective vertical brace 5 Welded on the upper surface of the rear protective cross brace 9, the rear protective vertical brace 5 is a U-shaped groove structure, one side of the web connecting plate 7 is provided with a positioning protrusion 13, and the U of the rear protective vertical brace The groove bottom of shaped groove is provided with the positioning hole 14 that cooperates positioning projection 13, and positioning projection 13 inserts in positioning hole 14 and realizes positioning, and vertical support reinforcement plate 6 is welded on the groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com