Ground solar photovoltaic support

A solar photovoltaic and ground technology, applied in the direction of photovoltaic power generation, etc., can solve the problems of restricting the promotion and application of solar photovoltaic technology, the overall size and weight, etc., to avoid the possibility of welding, save welding costs, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

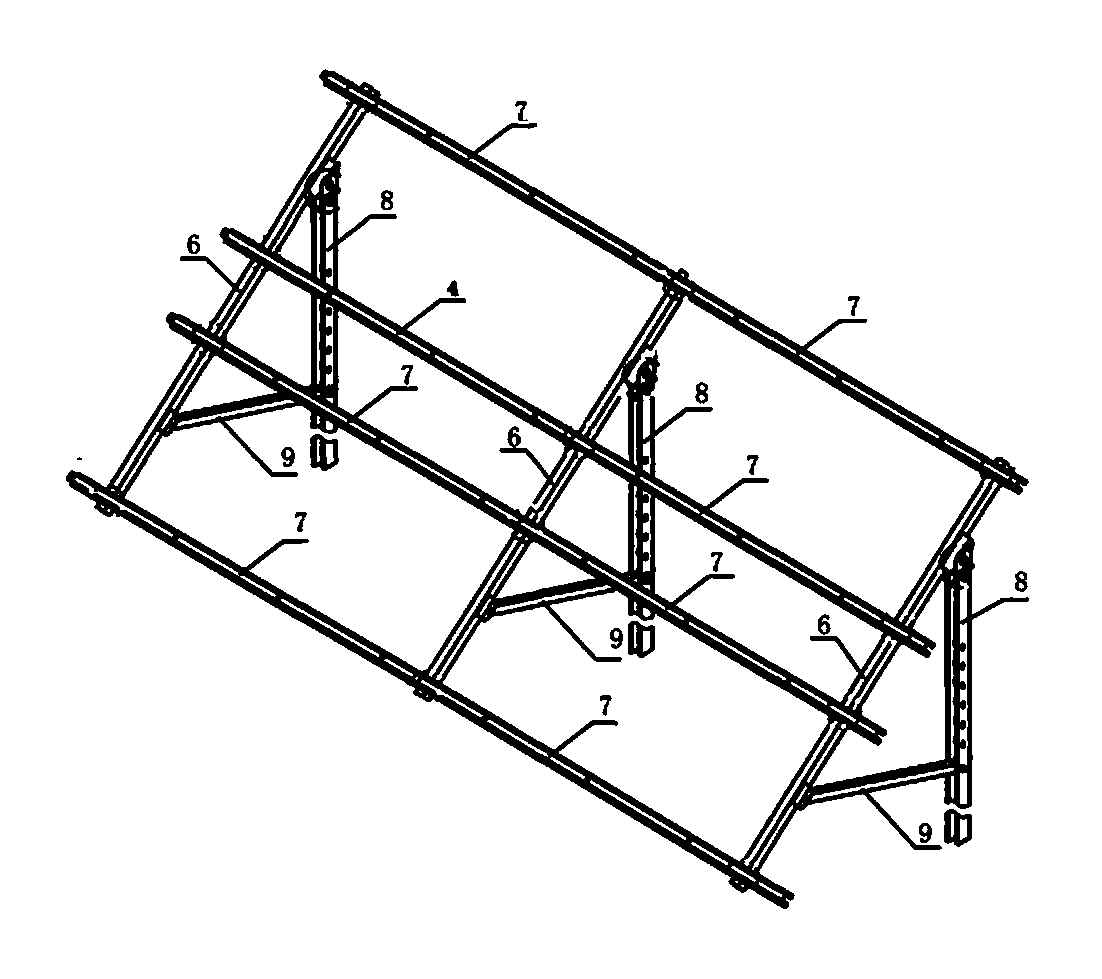

[0015] Embodiment: a ground solar photovoltaic support, including a beam 6, a track 7, a column 8, a connecting rod 9 and a triangular connection assembly, the column 8 is vertically inserted on the ground, and the at least two beams 6 are arranged in parallel at intervals, The crossbeam 6 is provided with several guide rail adjustment holes at intervals along its length direction, and the at least two guide rails are fixedly installed at the guide rail adjustment holes of the crossbeam 6 perpendicular to the direction of the crossbeam 6. The wall is fixedly connected, one end of the connecting rod 9 is fixedly connected with the side wall of the column 8, and the other end is fixedly connected with the beam 6 through a triangular connection assembly, and the beam 6, the column 8 and the connecting rod 9 form a triangular frame structure.

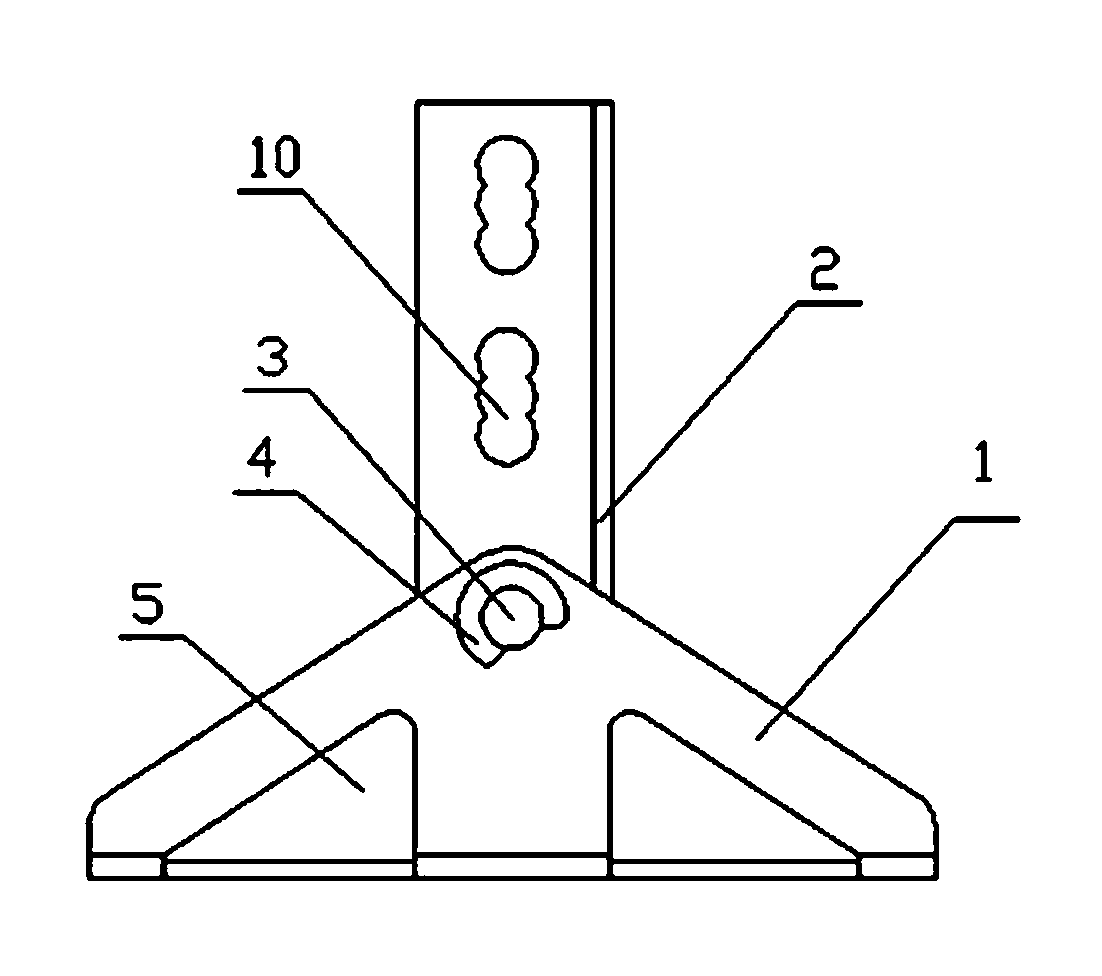

[0016] The triangular connection assembly includes a support 1, a connecting plate 2 and a connector, the U-shaped connecting plate 2 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com