Feeding mounting device of releaser

An installation device and releaser technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of poor operation convenience, low detection efficiency, inconvenient assembly, etc., and achieve high accuracy, reasonable structure, and reasonable detection process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

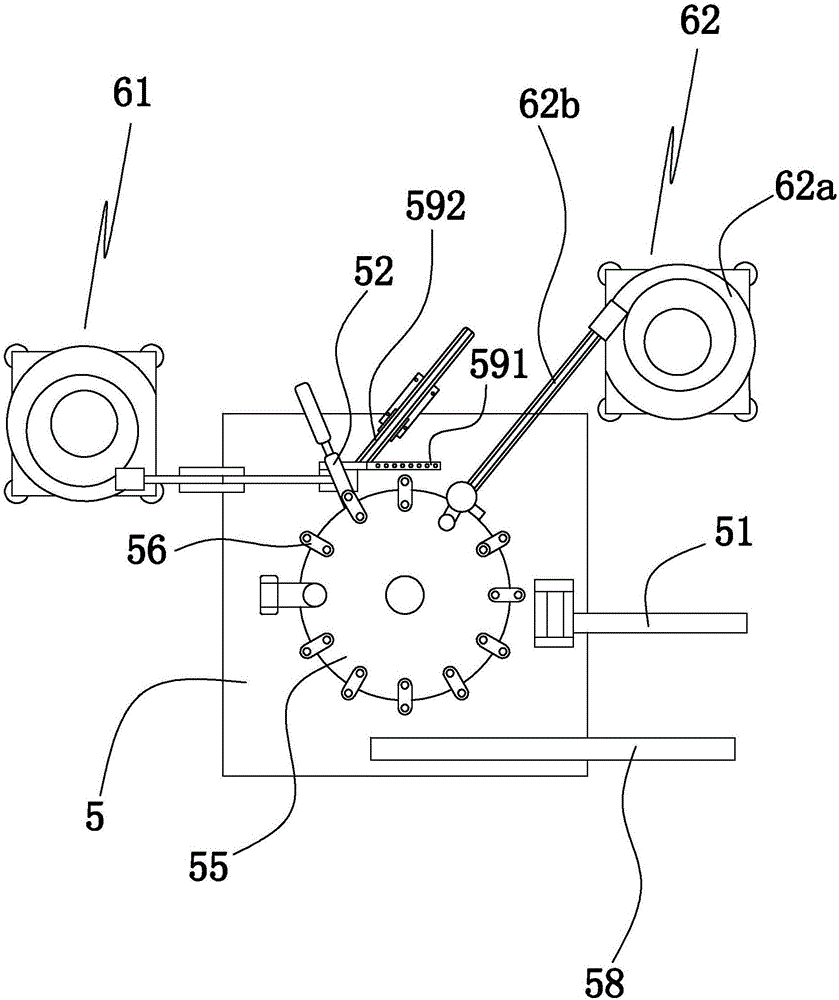

[0033] Embodiment 1: as Figure 1 to Figure 5In the shown embodiment, a feed installation device for a releaser is suitable for the assembly of a fire extinguisher valve (also called a releaser). The releaser 1 includes an upper valve seat 11, a push rod 12, a spring 13 and a stand Pipe seat 14, the upper valve seat is provided with valve inner passage 11a, and the upper sealing ring and the spool 12b for blocking the valve inner passage are arranged on the push rod, the upper sealing ring is at the top of the valve core, and the upper end of the upper valve seat is provided with There is an upper through hole connected with the passage in the valve, the upper sealing ring can slide and seal with the upper through hole, the upper sealing ring can be squeezed with the upper through hole, and the side wall of the upper valve seat is provided with an outlet connected with the passage in the valve Road 11b, the lower end of the upper valve seat is provided with an inlet passage co...

Embodiment 2

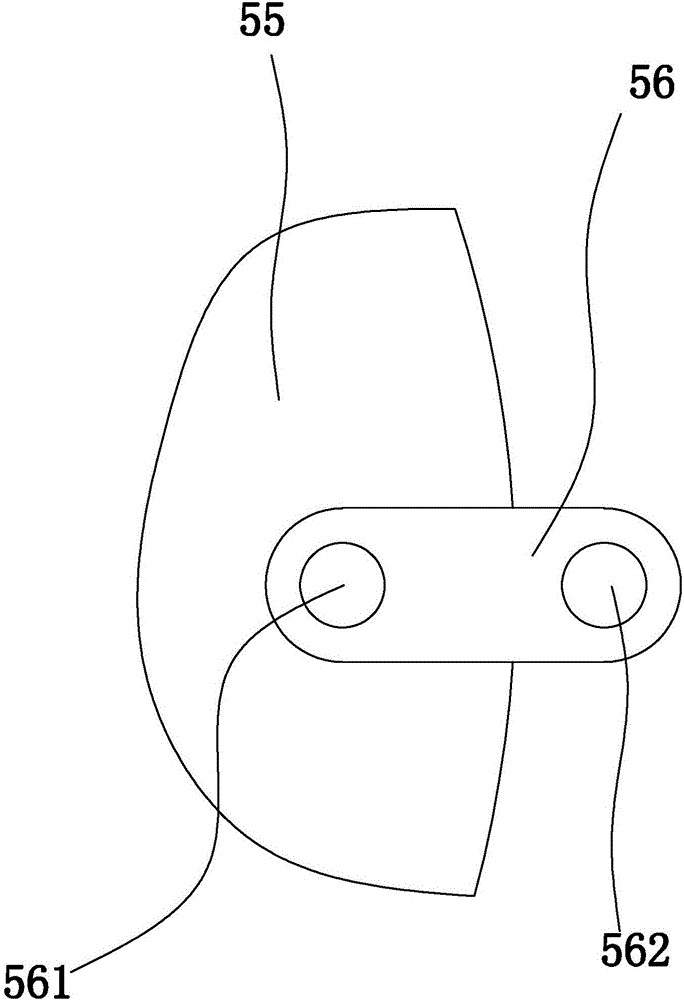

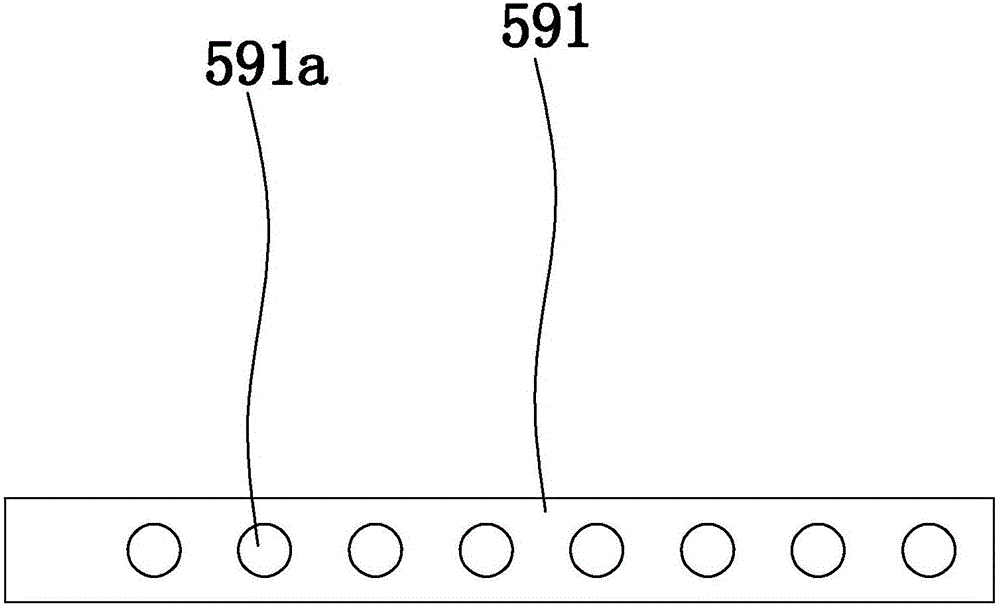

[0053] Embodiment 2: the basic structure and implementation mode of this embodiment are the same as embodiment 1, and its difference is, as Figure 6 to Figure 8 As shown in , the main workbench is equipped with a medium circulation detection device, which includes a first valve seat clamping manipulator for fixing the upper valve seat, a valve seat below the first valve seat clamping manipulator The first sealing inflatable seat 21, the blown structure 22 for being blown by the outlet jet airflow, and the valve opening structure 23 for pressing down the ejector rod, the valve opening structure includes a pressing plate 23a for pressing down the ejector rod and for driving The valve-opening electric cylinder 23b that the pressure plate moves up and down, the blown structure includes the blown seat 22a, the spring seat 22b arranged on the blown seat, the marking groove arranged on the blown seat, the blown spring 22c connected with the spring seat and The blown block 22d connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com