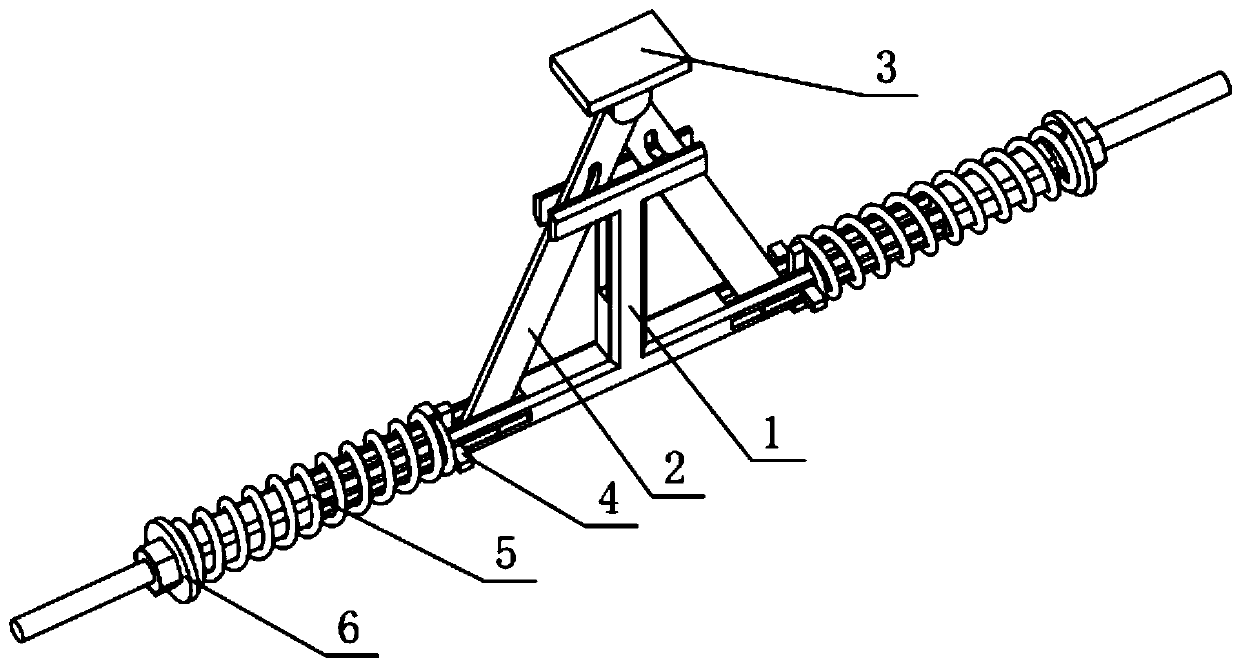

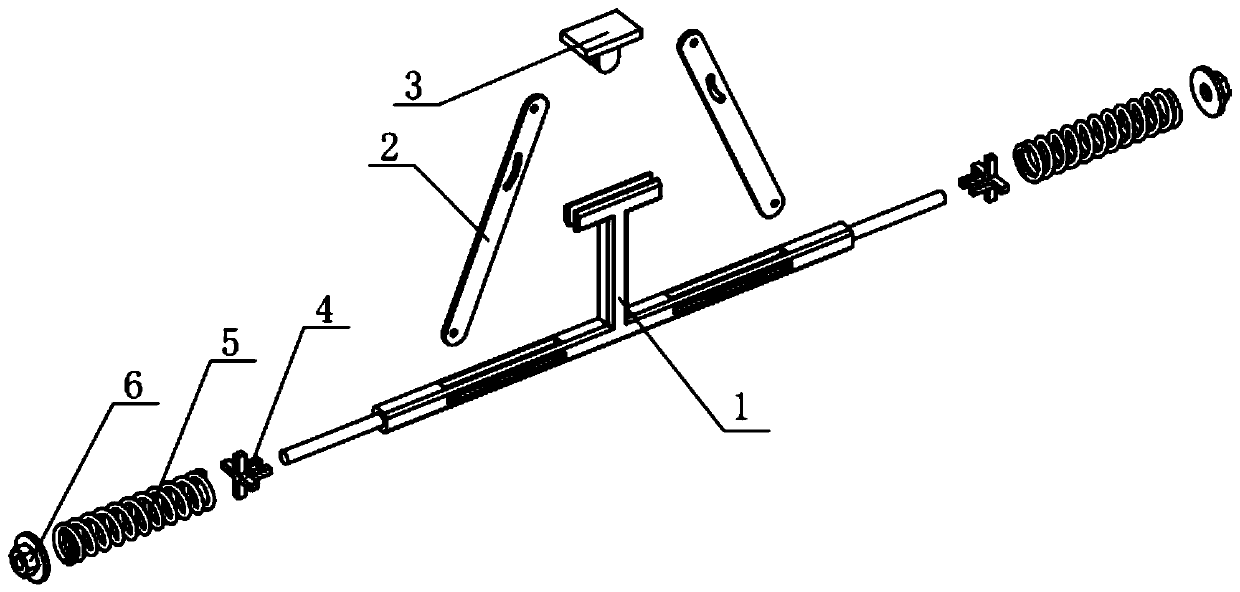

Underwater pressure-resistant structure self-adaptive constant-force fastening device and fastening method

A pressure-resistant structure and fastening device technology, applied in transportation and packaging, ship parts, ships, etc., can solve the problems of non-constant fastening force of elastic elements, difficult implementation, low installation efficiency, etc., to achieve convenient operation and structural Compact, efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

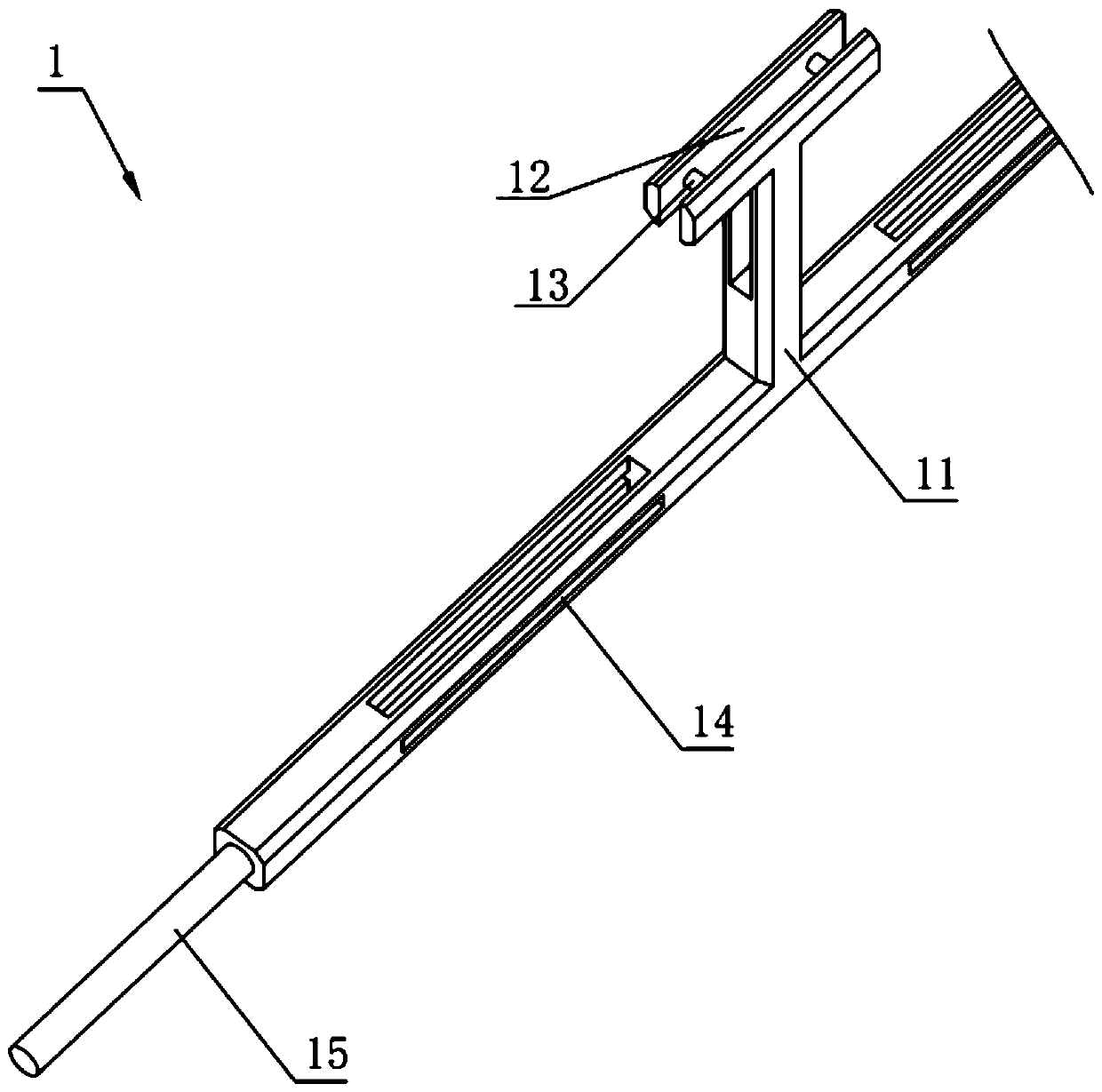

Examples

Embodiment

[0086] Example: Verification of Constant Fastening Force of Fastening Devices

[0087] In this embodiment, the fastening force of the pressure-resistant structural member 7 is designed at 1t, and the remaining dimensions are designed as shown in Table 1 below:

[0088]

[0089] Table 1 Size Design Parameters

[0090] According to formula (1), get the numerical solution of the center line function and the first order derivative of strip hole 21 on the lever 2, as shown in table 2 below:

[0091]

[0092] The center line function of table 2 strip hole 21 and the numerical solution of first order derivative

[0093] According to formulas (2) and (3), the numerical solutions of the forces F1, F2, F3, and F4 on the lever 2 are obtained, as shown in Table 3 below:

[0094]

[0095]

[0096] Table 3 Numerical solutions of the forces F1, F2, F3, and F4 on lever 2

[0097] According to formula (4), the numerical solution of the pretightening force F4 of the spring 5 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com