Temporary road rapid threading pipeline and threading method

A technology for temporary roads and threading pipes, applied in the directions of roads, roads, pavement details, etc., can solve problems such as line confusion, limiting the number of threading, and affecting the construction progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

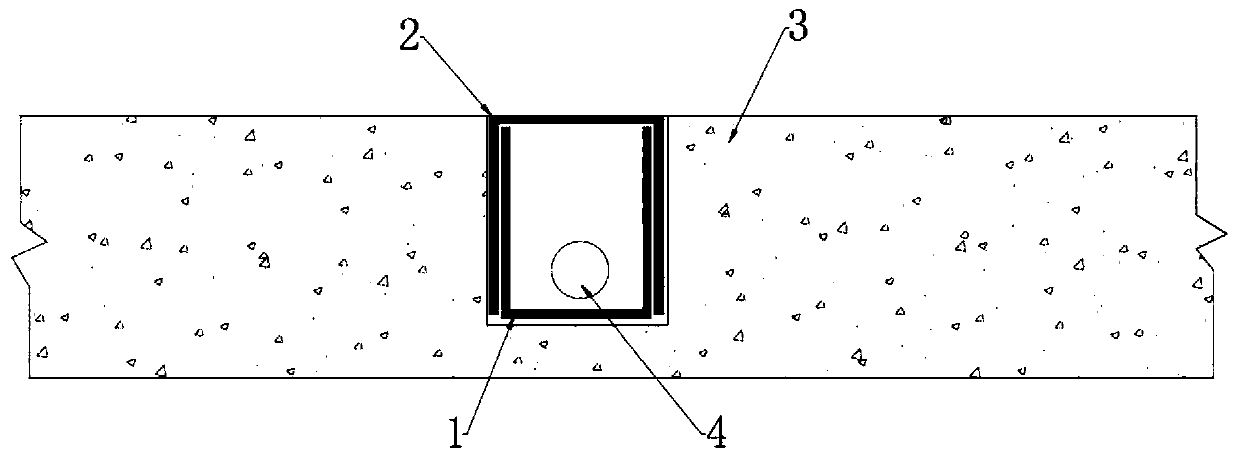

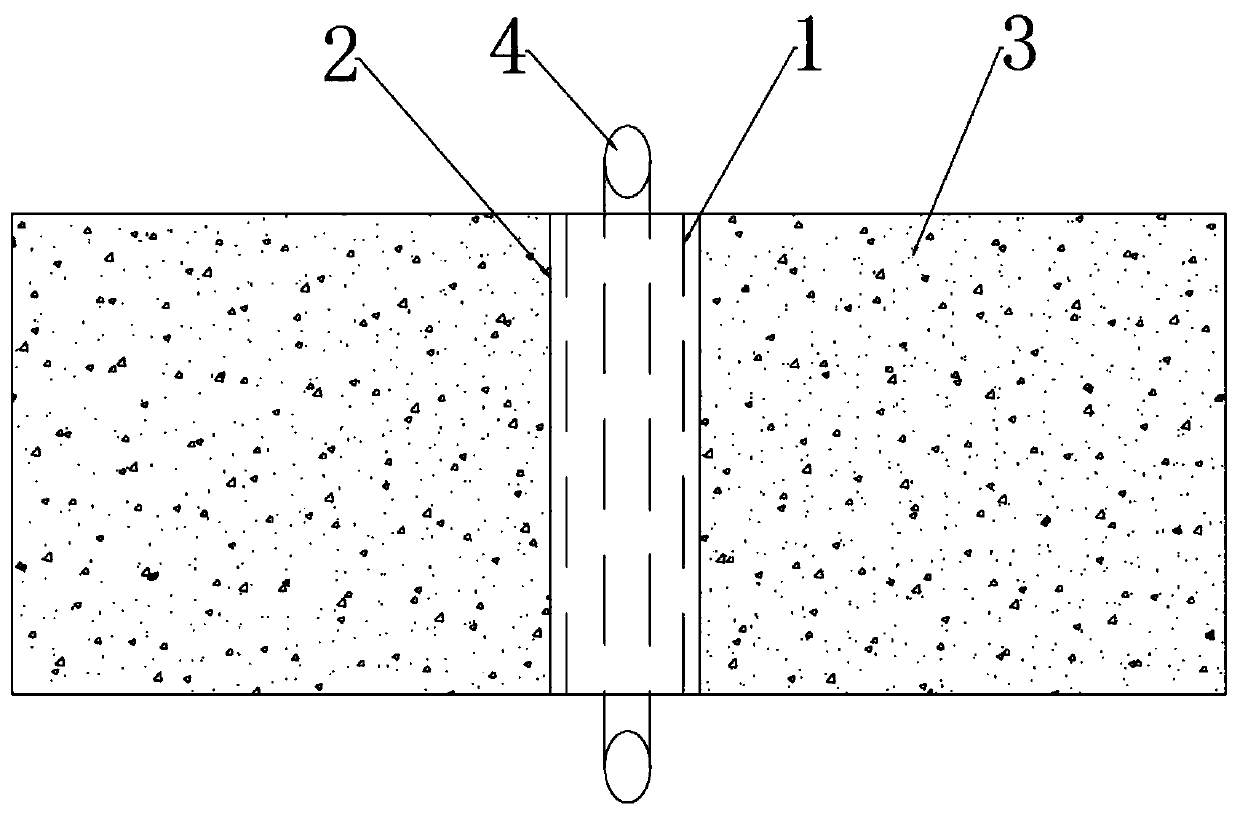

[0027] In one embodiment of the present invention, as figure 1 and figure 2 As shown, the temporary road rapid threading pipeline includes: first channel steel 1, second channel steel 2, concrete pavement 3, and line 4. The closed end of the first channel steel 1 is embedded in the concrete pavement 3, the open end of the first channel steel 1 is arranged inside the open end of the second channel steel 2, and the closed end of the second channel steel 2 is flush with the surface of the concrete pavement 3 Flat, the line 4 is set in the cavity surrounded by the first channel steel 1 and the second channel steel 2 .

[0028] Preferably,

[0029] The second channel steel 2 is provided with a mechanism for making the second channel steel 2 move up and down relative to the first channel steel 1 .

[0030] More preferably, the inner bottoms of the first chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com