Bent insensitive single-mode fiber with air cladding layer

A bend-insensitive, single-mode fiber technology, used in clad fibers, multi-layer core/clad fibers, etc., to solve problems such as incompatibility, high finished product, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

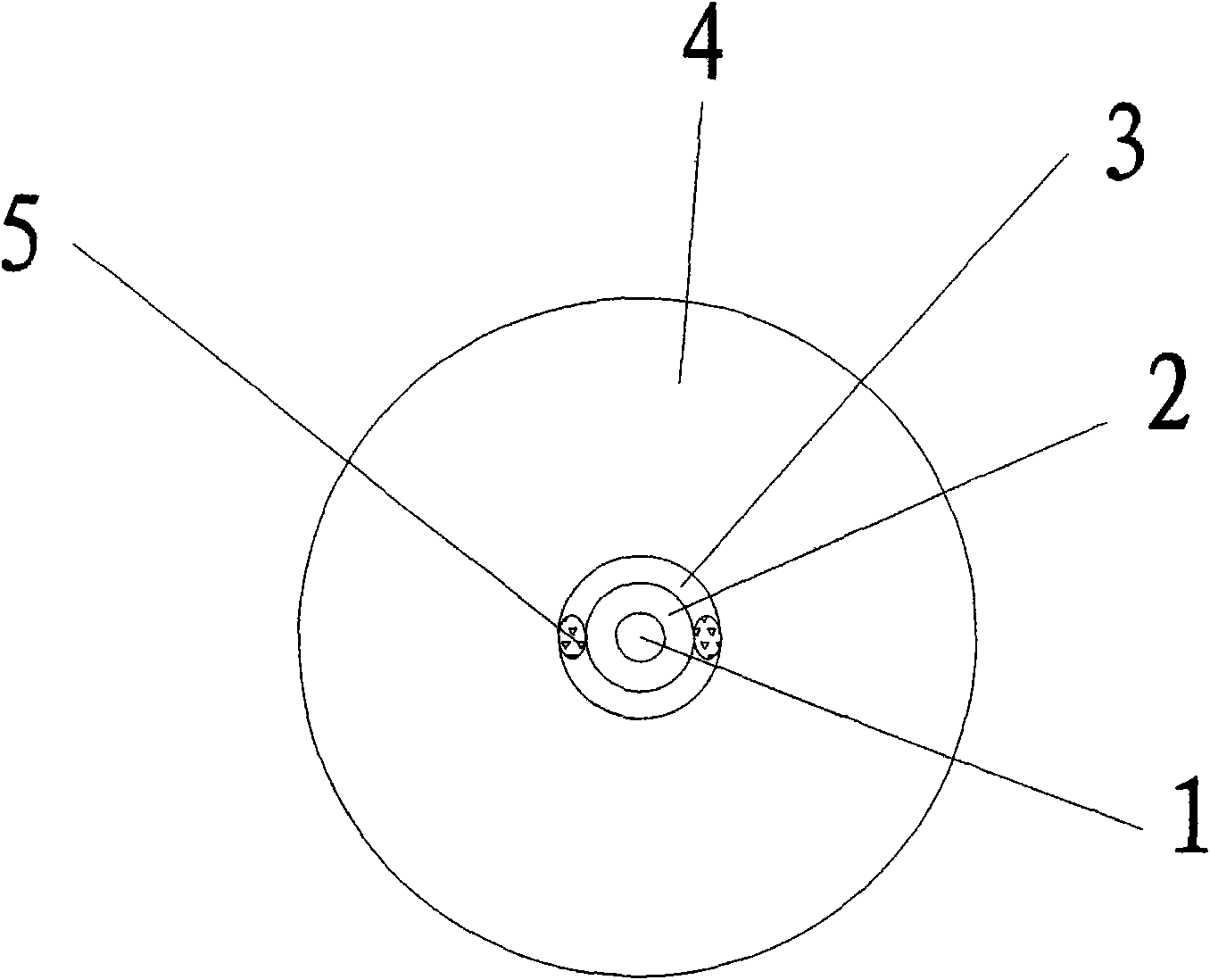

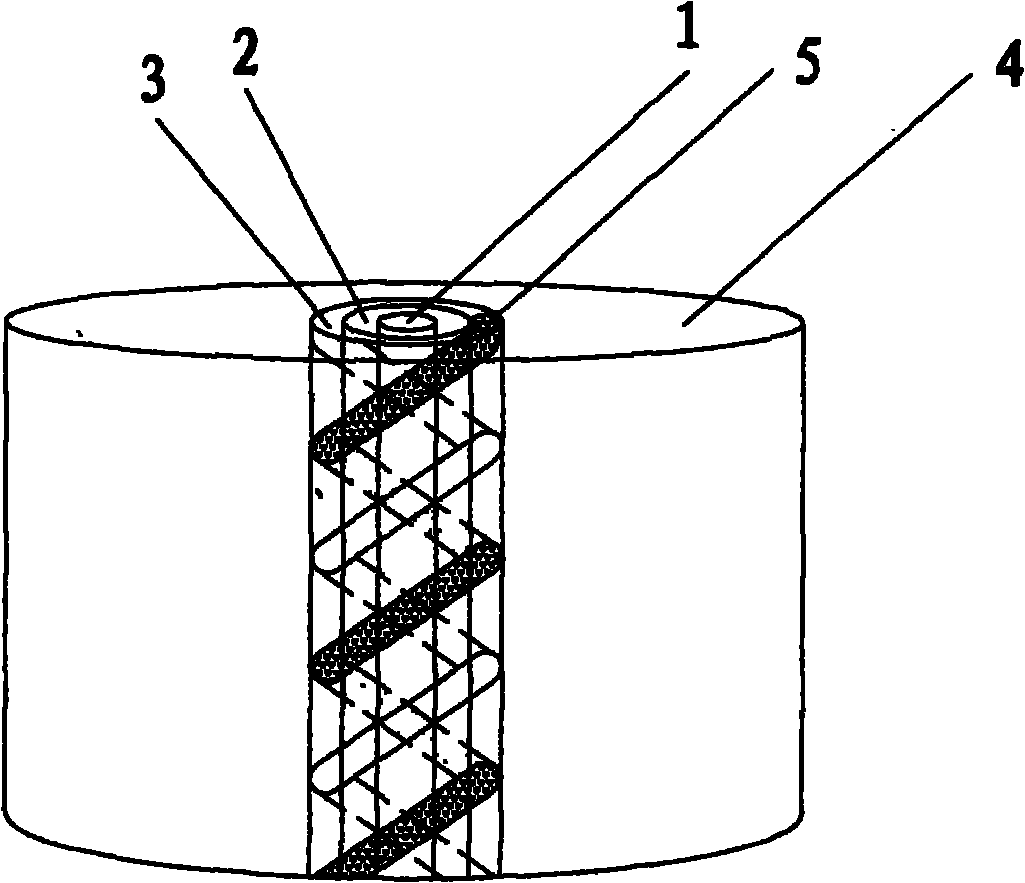

[0034] exist figure 1 , figure 2 In , it is assumed that the following waveguide structure parameters including the core layer 1 and three cladding layers are relative to the cladding layer 3 and 4:

[0035] The relative refractive index difference of the core layer 1 is about 0.60%, and the radius of the core layer is about 4 microns;

[0036] The relative refractive index difference of cladding 2 3 is about -50.00%, and the radius of cladding 2 3 is about 12 microns;

[0037] Cladding layer one 2 and cladding layer three 4 are pure silica glass layers, and their refractive index is pure silica glass refractive index nc. The radius of cladding one 2 is about 10 microns, and the radius of cladding three 4 is 62.5 microns.

[0038] The properties of the resulting fiber are as follows:

[0039] The cut-off wavelength of the fiber is ≤1310nm, the mode field diameter of the fiber at 1310nm wavelength is 7.8-10.2 microns, and the typical bending additional loss is less than 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Additional bending loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com