Roadway support system anti-impact character testing device and method under rockburst simulating condition

A roadway support and characteristic testing technology, which is applied to mining equipment, tunnels, tunnel linings, etc., can solve the problems of safety and hidden dangers in the support system, and achieve the effects of good failure characteristics, good pertinence and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

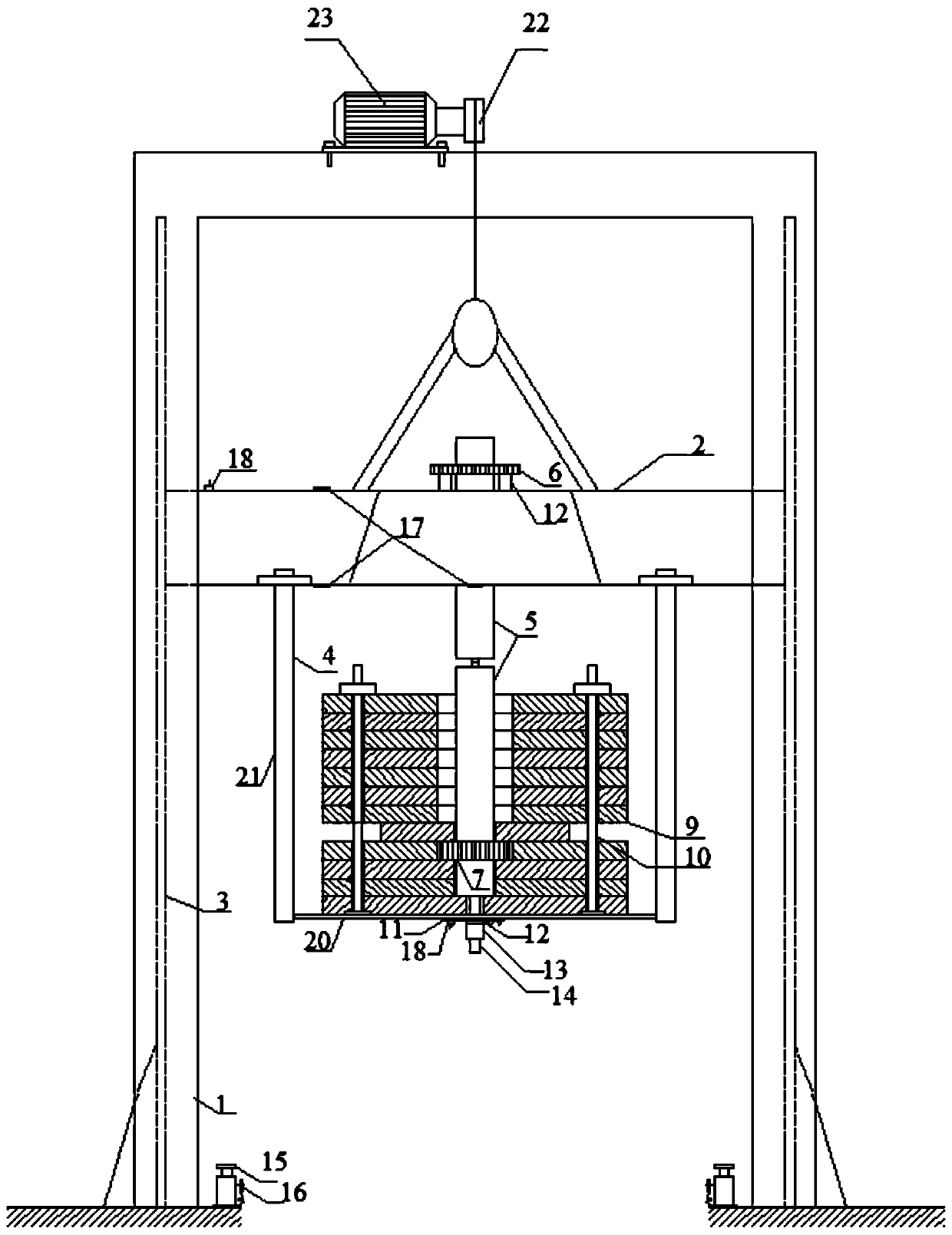

[0025] refer to Figure 1 to Figure 2 The embodiment of the device and method for testing the anti-shock characteristics of the roadway support system under the simulated rockburst condition of the present invention will be further described.

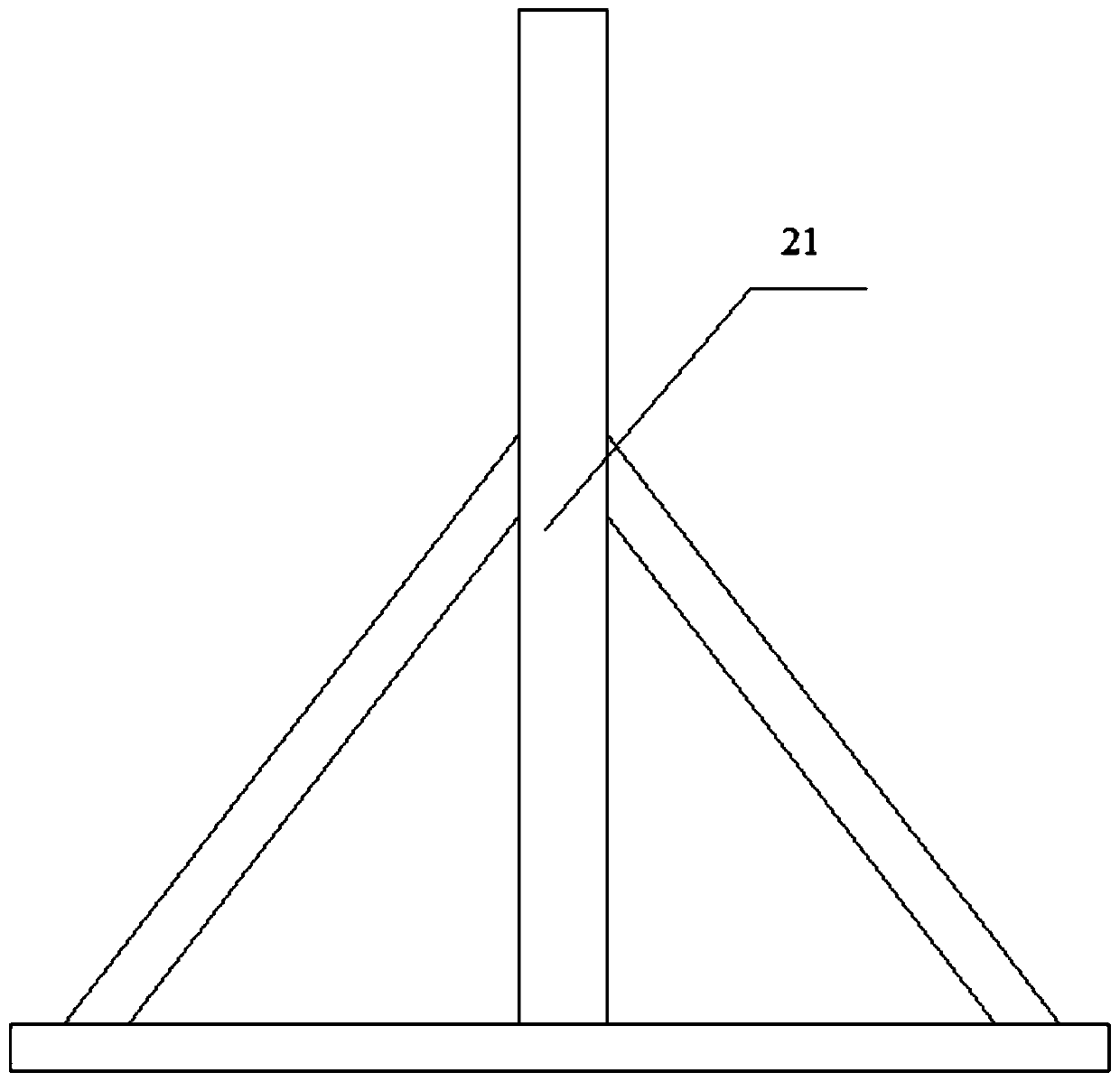

[0026] The device for testing the impact resistance of the roadway support system under simulated rockburst conditions includes a main frame 1 and an anchor rod 14. The top of the main frame 1 is provided with a lifting motor 23, and the lifting motor 23 is connected to an impact through a winding wheel 22. Beam 2, the impact beam 2 is provided with two uprights 21, a surface support installation frame 4 is arranged between the two uprights 21, and a surface support member 20 is arranged inside the surface support installation frame 4, The anchor rod 14 is anchored in the upper and lower sections of the steel pipe 5 through an anchoring agent, and the upper and lower flanges 6 and 7 are provided at the deviated ends of the upper and low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com