Smoke emission load adjusting and control system of thermal power plant

A regulation control, thermal power plant technology, applied in combustion methods, dispersed particle filtration, lighting and heating equipment, etc., can solve problems such as affecting the normal use of equipment, reducing dust removal efficiency, output inconsistent with design, etc., to overcome the distribution of flue gas flow uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

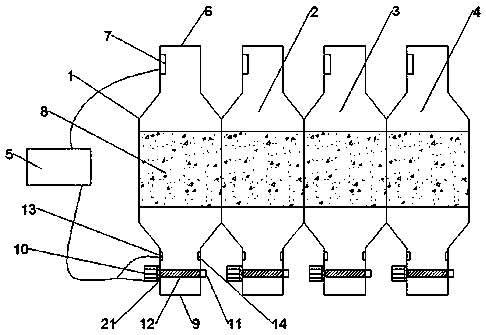

[0021] Such as Figure 1-2 As shown, according to the embodiment of the present invention, the dust collector smoke discharge adjustment control device of a thermal power plant includes a smoke exhaust pipe 1, a smoke exhaust pipe 2, a smoke exhaust pipe 3, a smoke exhaust pipe 4 and a controller 5. The tops of the smoke exhaust pipe one 1, the smoke exhaust pipe two 2, the smoke exhaust pipe three 3 and the smoke exhaust pipe four 4 are respectively provided with a smoke exhaust port 6, and the inner side wall of the smoke exhaust port 6 Smoke sensors 7 are respectively provided, and the middle positions of the smoke exhaust pipe 1, the smoke exhaust pipe 2, the smoke exhaust pipe 3 and the smoke exhaust pipe 4 are respectively provided with smoke purification devices. 8. The bottom ends of the exhaust pipe 1, the exhaust pipe 2, the exhaust pipe 3 and the exhaust pipe 4 are respectively provided with a smoke inlet 9, and the smoke inlet 9 is provided with a motor 10, the ot...

Embodiment 2

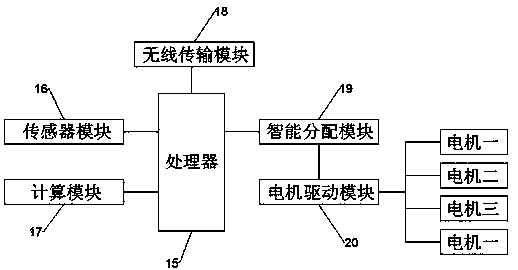

[0026] Such as Figure 1-2 As shown, the inside of the controller 5 is respectively provided with a processor 15, a sensor module 16, a computing module 17, a wireless transmission module 18, an intelligent distribution module 19 and a motor drive module 20, the sensor module 16, the computing module Module 17, the wireless transmission module 18 and the intelligent distribution module 19 are respectively connected to the processor 15, the intelligent distribution module 19 is connected to the motor drive module 20, the motor 10 is connected to the smoke inlet A buffer gasket 21 is arranged between the ports 9, and the buffer gasket 21 is made of heat-insulating and fireproof material, and the smoke sensor 7, the angle sensor 11, the adjusting plate 12, the smoke flow sensor one 13 and the The two smoke flow sensors 14 are heat-resistant and fireproof materials respectively, and the smoke exhaust pipe one 1, the smoke exhaust pipe two 2, the smoke exhaust pipe three 3 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com