System and adjustment method for flue gas flow balance adjustment of dust collector in thermal power plant

A technology of balance adjustment and flow adjustment, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., can solve problems such as uneven distribution of flue gas flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

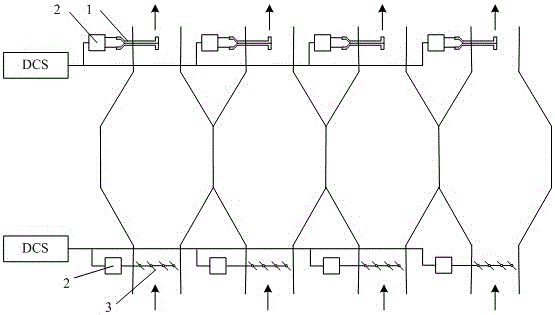

[0030] Such as figure 1 As shown, the flue gas flow balance adjustment system of the thermal power plant dust collector according to the present invention includes a control system, an air volume detection device 1 and a flow regulating device 3 . The control system is used to receive the flue gas volume information collected by multiple air volume detection devices 1 at the outlets of each chamber of the dust collector, analyze the collected flue gas volume information, and then output control signals to control the entrances of each chamber of the dust collector The flow regulating device 3 at the dust collector adjusts the air intake volume of each chamber of the dust collector; the air volume detection device 1 is used to collect the flue gas volume information at the outlet of each chamber of the dust collector, and the outlet of each chamber of the dust collector is equipped with an air volume detection device 1 The flow regulating device 3 is used to adjust the air inta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com