Online real-time combustion optimization technology method for coal-fired power plant boiler

A combustion optimization, coal-fired power plant technology, applied in the control of combustion, lighting and heating equipment, etc., can solve problems such as incomplete coverage, and achieve the effects of optimization of combustion organization, economic improvement, and optimization of boiler combustion organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. In addition, it should be understood that after reading the teachings of the present invention, those skilled in the art can make various changes or modifications to the present invention, and these equivalent forms also fall within the scope defined by the appended claims of the present application.

[0042] The invention provides a coal-fired power plant boiler online real-time combustion optimization technology method, comprising the following steps:

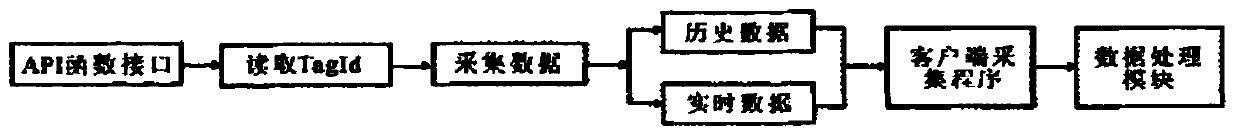

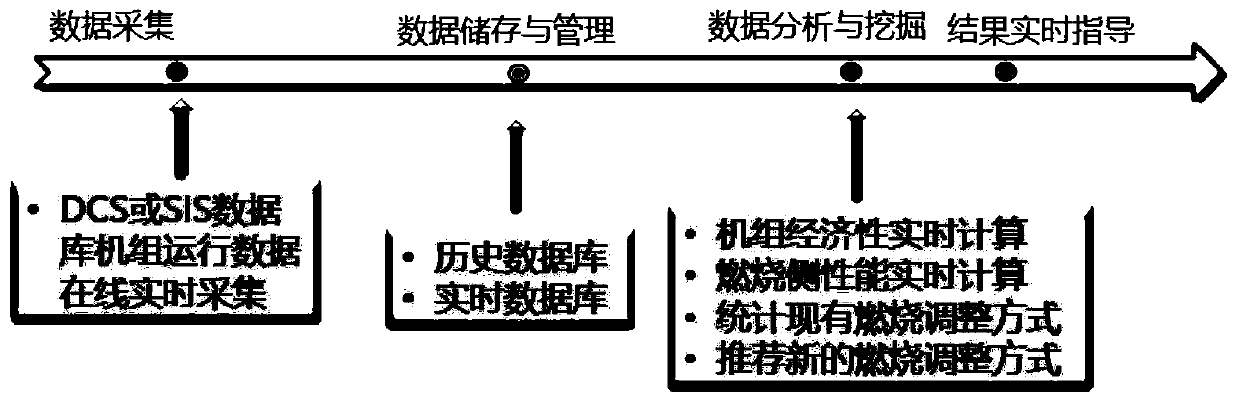

[0043] Step 1. Collect the operating DCS data or SIS data of boilers and steam turbines, sort out and sort out the DCS data or SIS data, form a historical database and an online real-time database, and store them on the set on-site server. On this basis, based on the data o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com