Automatic shirt lighting detection equipment

A testing equipment and a technology for illuminating shirts, which are used in measuring devices, optical testing of flaws/defects, material analysis by optical means, etc., can solve the problems of inability to fully open, easy to work fatigue, etc., and achieve the effect of convenient detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

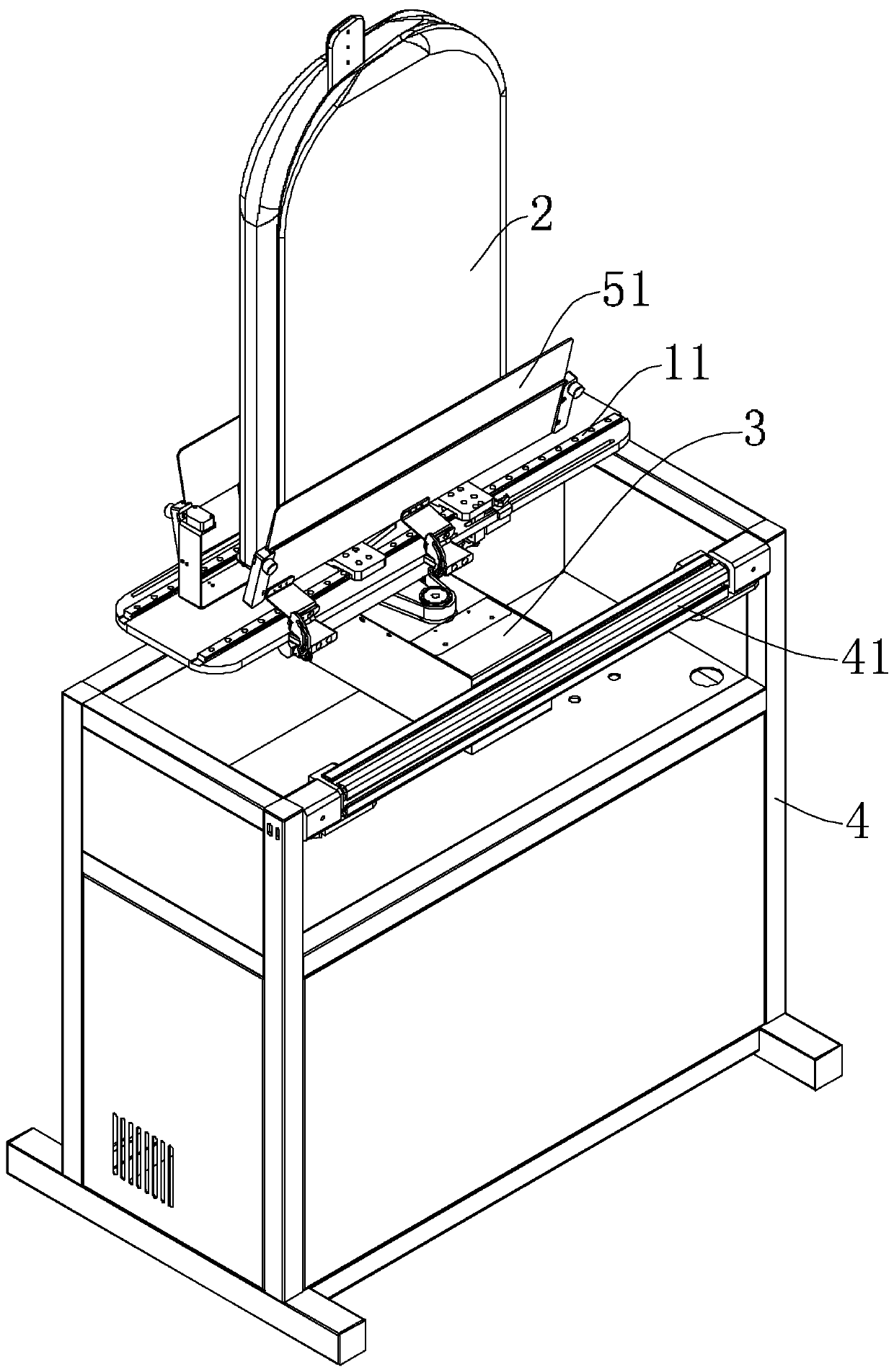

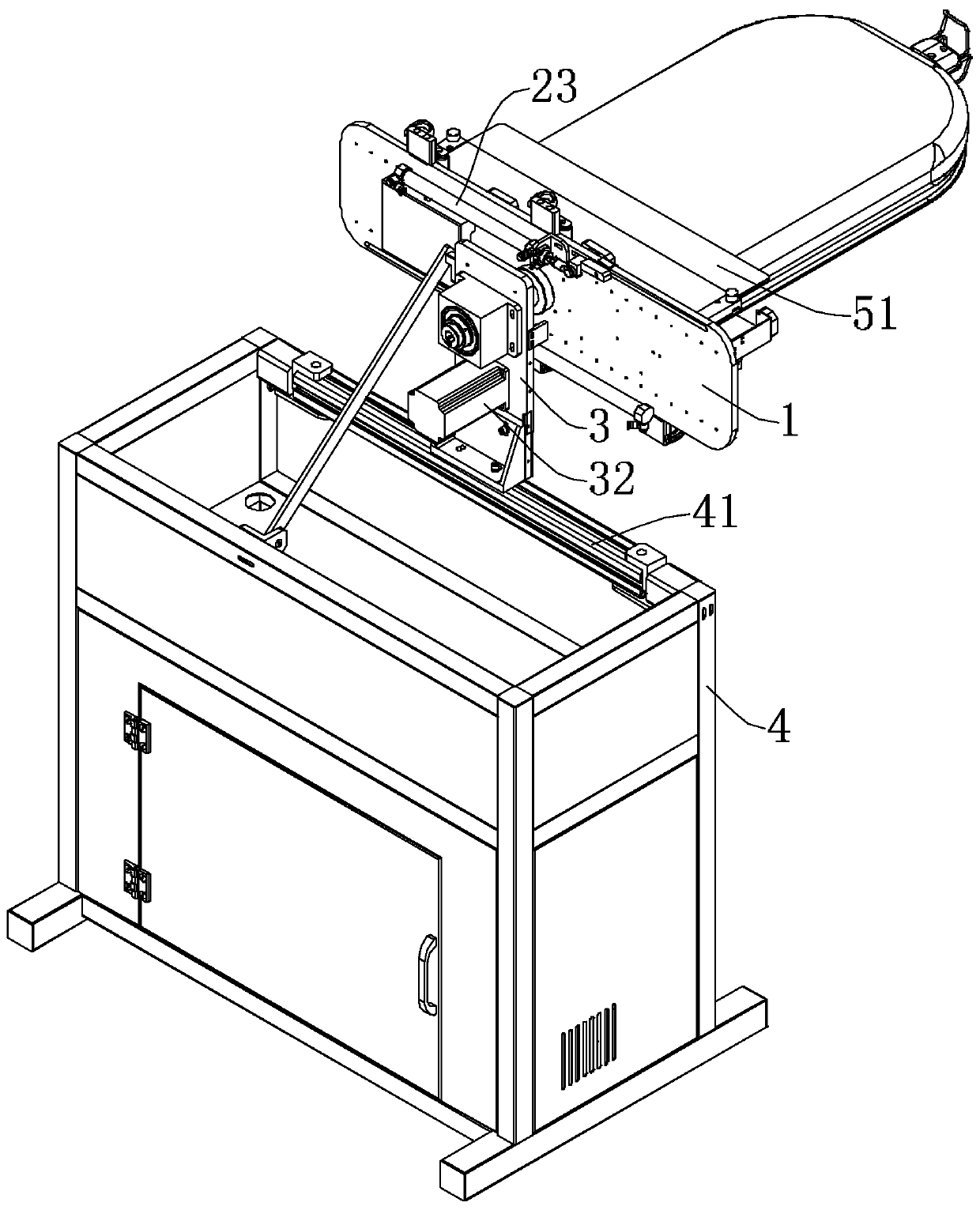

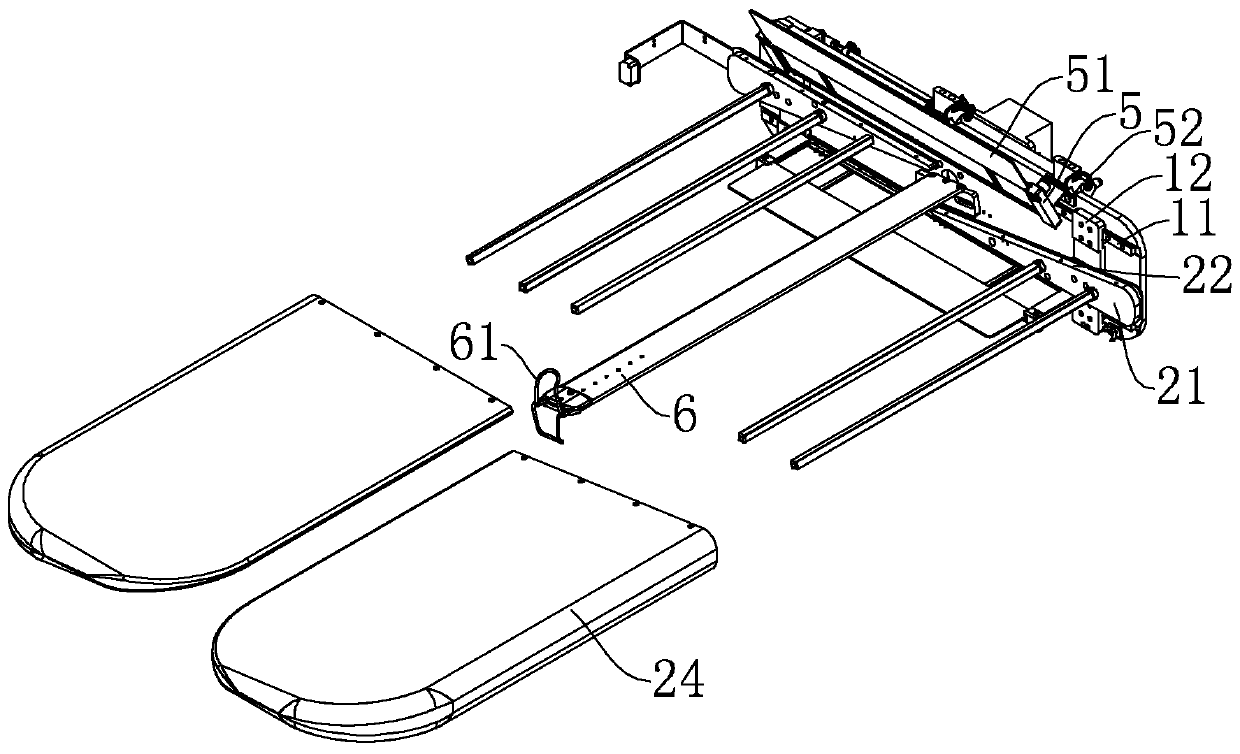

[0022] Figure 1 to Figure 5 Shown is the structural representation of the present invention.

[0023] Wherein the reference numerals are: mounting plate 1, guide rail 11, slider 12, flat type shirt lamp 2, three-sided rounded lamp holder 21, hypotenuse 22, first driver 23, flat type shirt lampshade 24, base Seat 3, first rotating shaft 31, second driver 32, mounting bracket 4, second rotating shaft 41, shading mounting bracket 5, shading plate 51, arc groove 52, support arm 6, collar hook 61.

[0024] The automatic shirt inspection equipment of the present invention comprises a mounting plate 1, which is arranged vertically. The side of the mounting plate 1 is provided with a guide rail 11. The guide rail 11 is provided with two horizontally arranged and movable along the guide rail 11. Shirt lamp 2. The back of the mounting plate 1 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com