Automatic feeding device

A technology of feeding device and movable installation, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of high manufacturing cost, complex structure, and inability to adapt to automatic transmission of parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

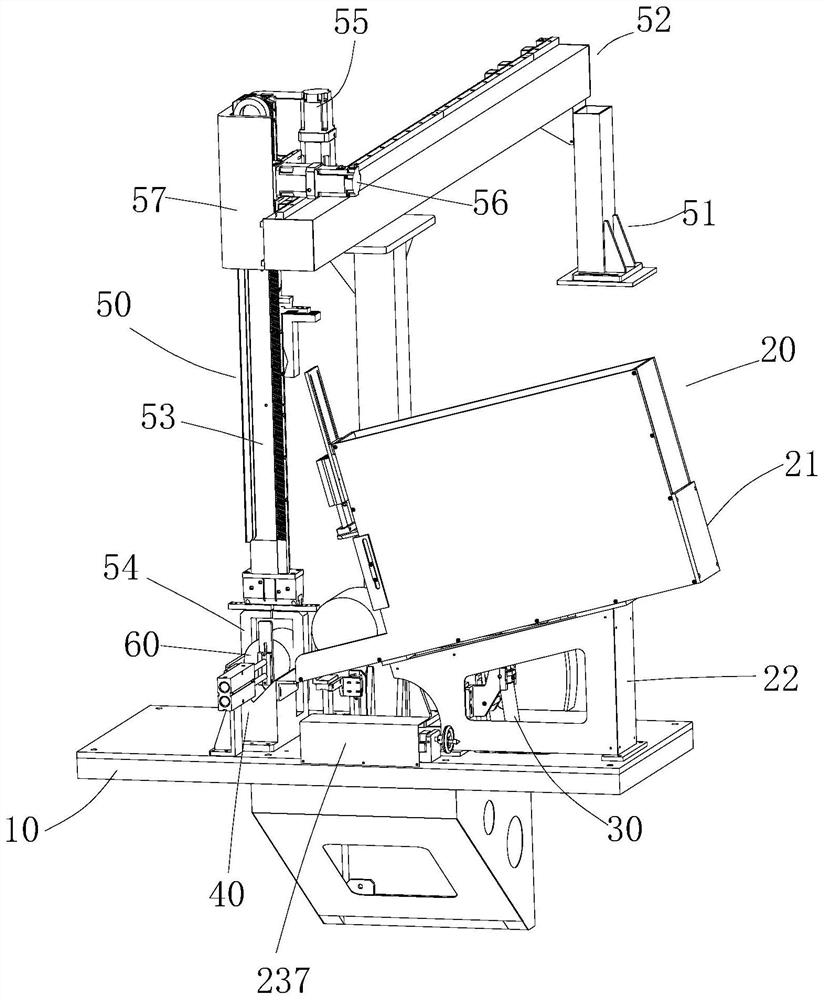

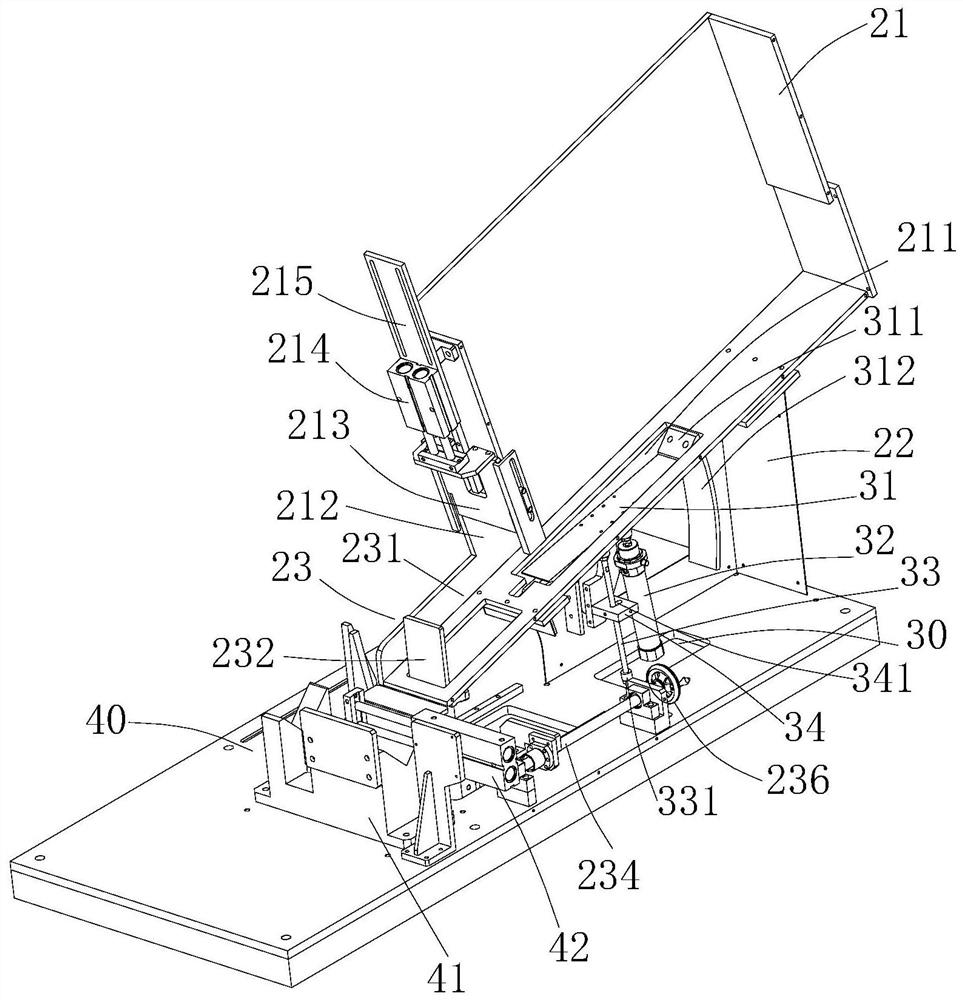

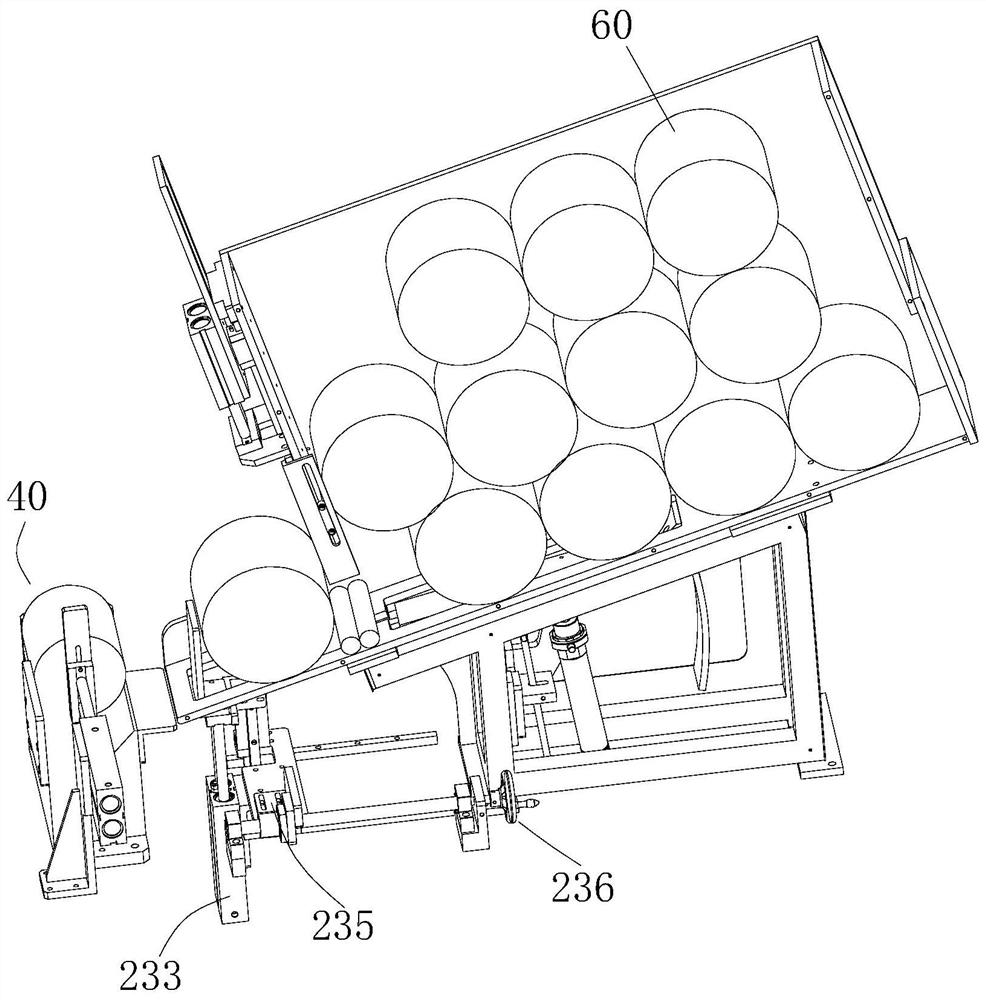

[0050] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0051] The automatic feeding machine is a device that automatically adds materials to the processing unit. Compared with the traditional manual feeding, it has a higher degree of automation, and the feeding efficiency and delivery position accuracy are also higher. Most of the feeders on the market can only realize the feeding process of parts of a single size. With the continuous updating of personalized products, the structure of the existing feeder cannot adapt to the automatic transmission of parts of various varieties and sizes, and its structure is relatively complicated. Manufacturing costs are higher. The present invention mainly provides an automatic feeding device for the above two problems, which can effectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com