Connecting pipe automatic placement control system and method

A control system and control method technology, applied in loading/unloading, conveyors, conveyor objects, etc., can solve the problem of low efficiency of joint pipe placement, and achieve the effect of improving placement efficiency and accurate feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

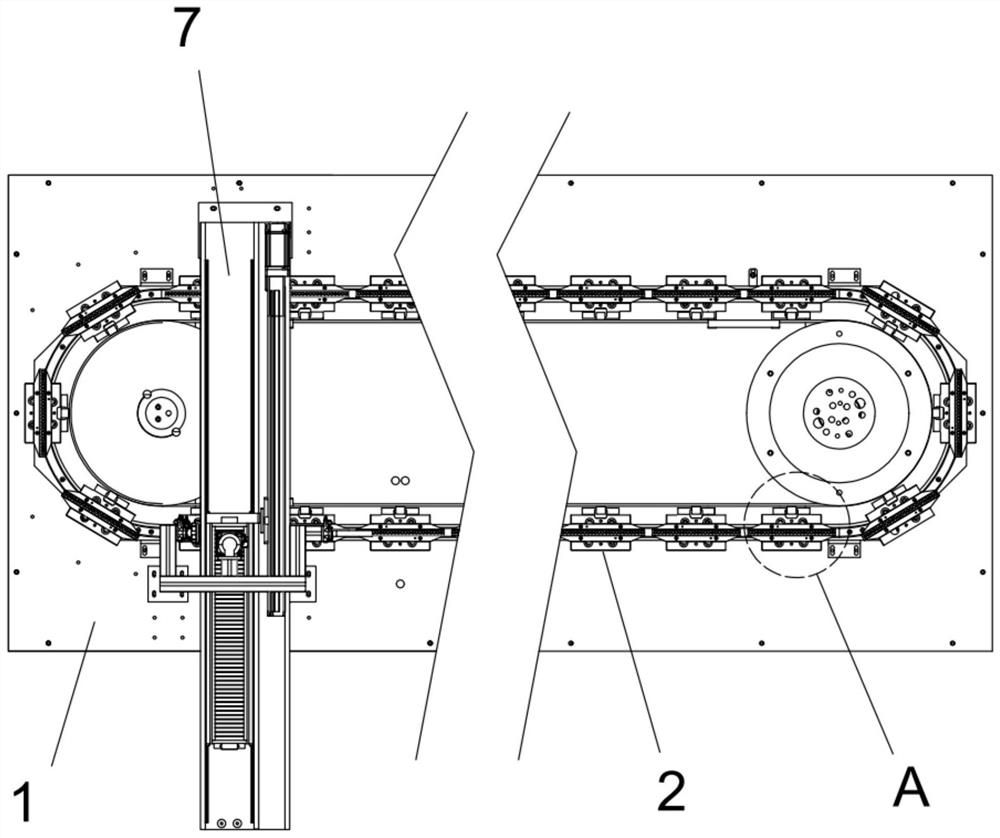

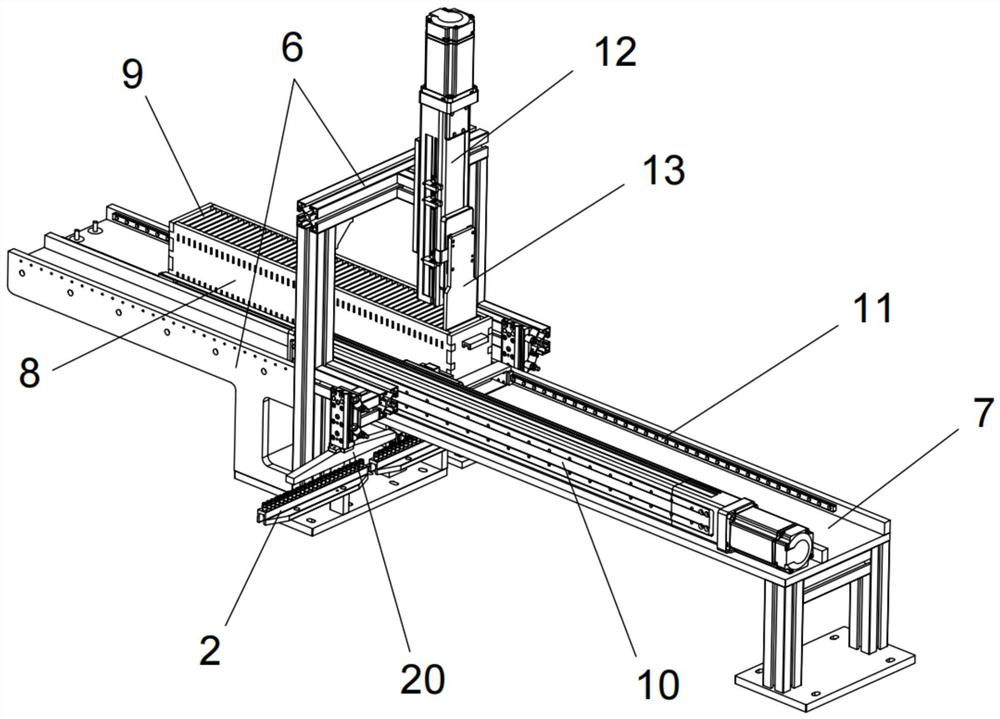

[0042]The tube strip automatic placement control system includes a transmission base 1, a tube strip transmission device, a feeding base 6, a feeding device and a flattening device.

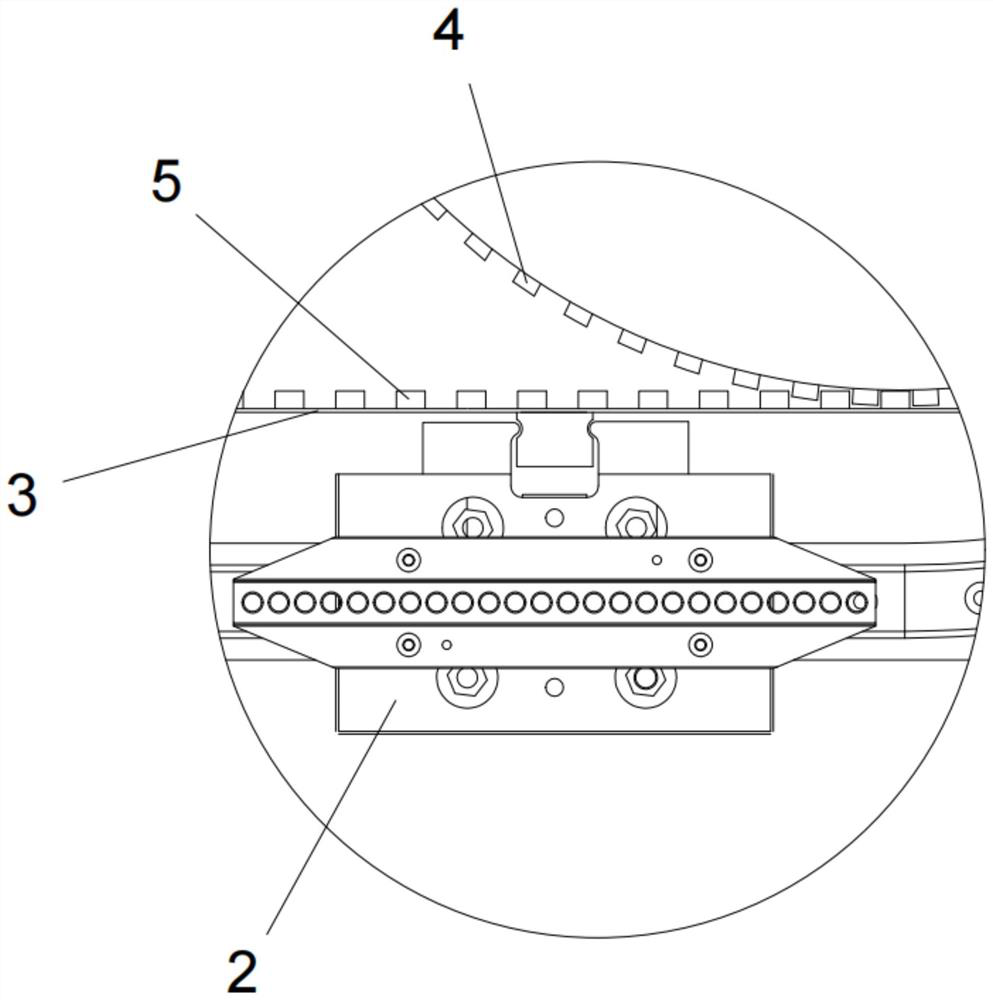

[0043] as attached figure 1 As shown, the tube strip transport device is arranged on the transmission base 1, and the tube strip transport device is used for transporting the tube tube placement tray 2. The tube strip placement tray 2 includes a slider and a fixing plate. The placement slot of the tube, the placement slot matches the shape of the joint tube, and the joint tube refers to the consumables connected in sequence by multiple reaction tubes, that is, the number of placement slots is multiple and distributed sequentially. The fixing plate is detachably connected to the sliding block, specifically, the fixing plate and the sliding block are detachably connected through fixing screws.

[0044] The joint transmission device includes a driving wheel, a driven wheel, and a conveyor belt 3 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com