Interconnecting strip positioning device for series welding of photovoltaic cells

A positioning device and photovoltaic cell technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as poor welding quality, inability to adapt to automatic positioning, leveling and deviation correction of interconnection strips, and lack of self-inspection functions for core components. Achieve the effect of improving quality, solving the self-inspection function of core components, and realizing automatic and accurate feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

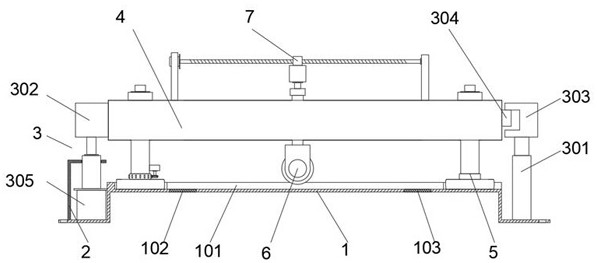

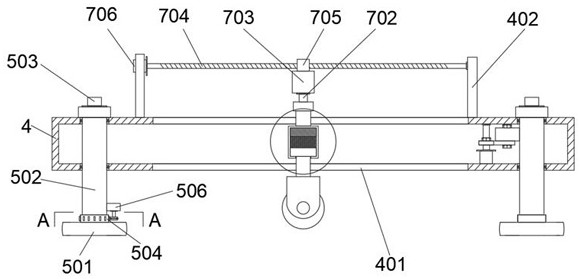

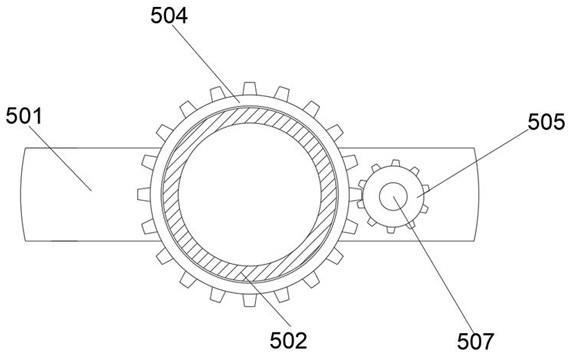

[0043] like figure 1 - Image 6 As shown, an interconnecting strip positioning device for photovoltaic cell string welding, including positioning convex plate 1, reclaiming drive assembly 3, positioning box 4, negative pressure correction assembly 5, tiling induction assembly 6 and tiling drive assembly 7. The positioning convex plate 1 is provided with a positioning groove 101. The bottom end of the positioning groove 101 is symmetrically provided with a first sensing area 102 and a second sensing area 103. The first sensing area 102 and the second sensing area 103 The principle of determining a straight line according to two points is used for induction imaging. The reclaiming drive assembly 3 is set on both sides of the positioning convex plate 1 and is used to drive the positioning box 4 to lift and rotate, so as to facilitate the suction of the negative pressure deviation correction assembly 5. For solid and reclaiming, the negative pressure rectifying component 5 and th...

Embodiment 2

[0057] like Figure 7 As shown, based on Embodiment 1, an interconnection bar positioning device for photovoltaic cell string welding, which is connected to a central control panel based on a network signal, and the central control panel includes a data acquisition module, a deviation correction module, a data processing module, and a processing module. device and component execution module;

[0058] The data acquisition module is used to collect the positioning state information of the interconnecting strip and the operating condition state information of the tile structure and send them to the deviation correction module and the data processing module respectively; the positioning state information of the interconnecting strip is the first sensing area 102 and the second sensing area 102. Area 103 collects the synthesized grayscale picture of the offset state of the interconnected bars; and the operating condition state information of the tiled structure is obtained by the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com