3D printing equipment with printing head convenient to replace

A 3D printing and printing head technology, which is applied in processing drive devices, additive processing, etc., can solve the problem that the printer cannot replace the printing head, and achieve the effect of reducing shaking and improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

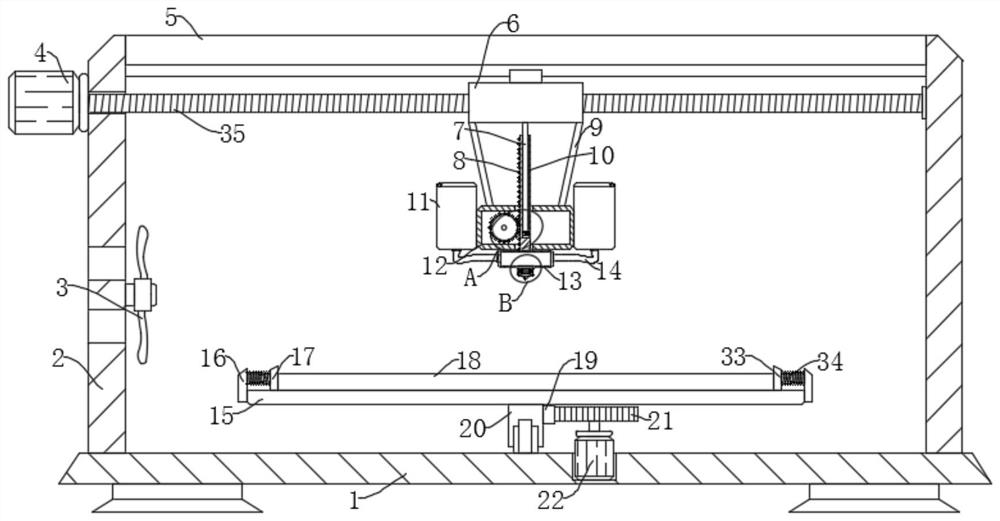

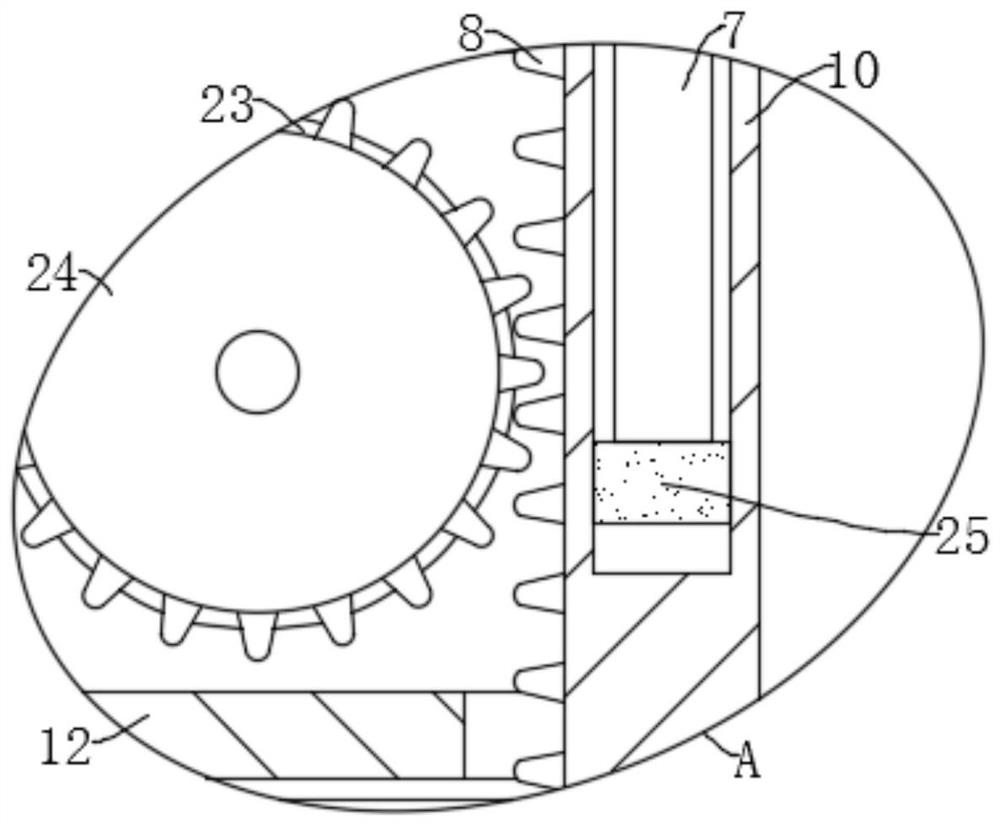

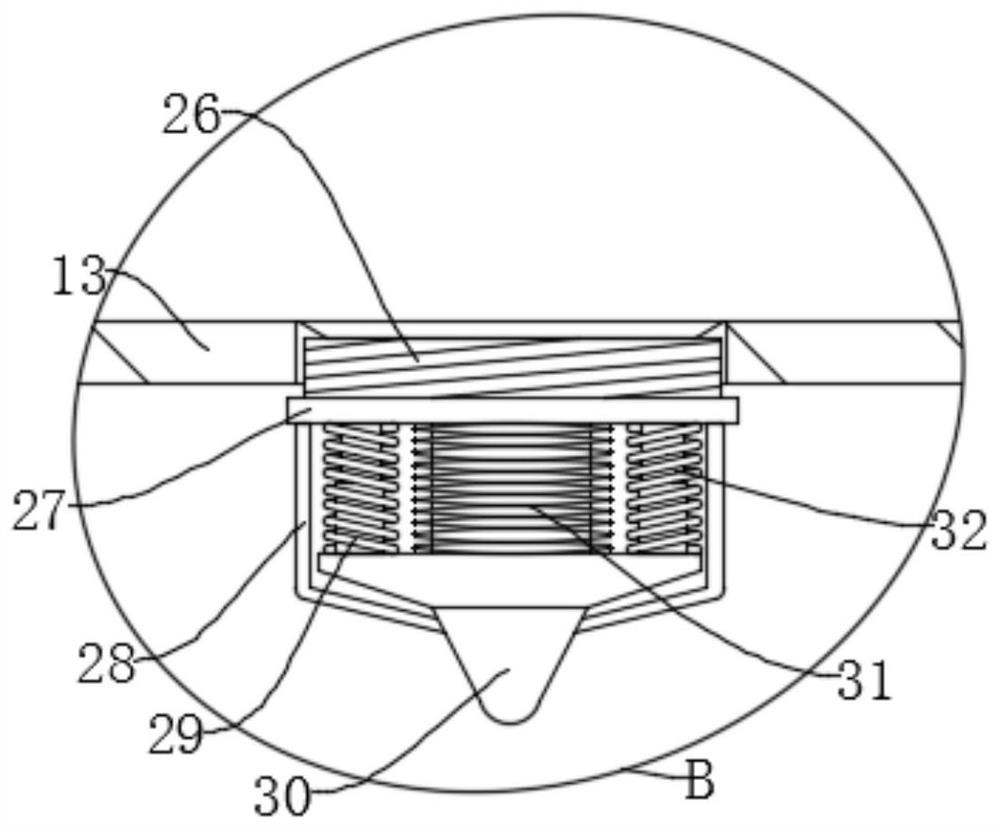

[0027] refer to Figure 1-5 , a 3D printing device for easy replacement of print heads, comprising a base 1, two connecting plates 2 are symmetrically arranged on the top of the base 1, the same top plate 5 is fixedly connected between the two connecting plates 2, and the bottom of the top plate 5 is slidingly connected There are connecting pipes 6, one side of one of the connecting plates 2 is provided with a drive assembly for driving the connecting pipe 6 to move, the bottom of the connecting pipe 6 is provided with a plurality of connecting frames 9, and the bottom ends of the multiple connecting frames 9 are fixedly connected with The same installation box 12, the installation box 12 runs through and is slidably connected with a casing 10, and the bottom end of the casing 10 is fixedly connected with a feed tank 13, and two feed boxes 11 are arranged symmetrically on both sides of the feed tank 13, and the feed tank The bottom of 13 is threadedly connected with a threaded...

Embodiment 2

[0029] Further improved on the basis of embodiment one: with reference to Figure 1-5, a 3D printing device for easy replacement of print heads, including a base 1, two connecting plates 2 are symmetrically arranged on the top of the base 1, a cooling fan 3 is arranged on the inner side of one of the connecting plates 2, and the two connecting plates 2 are fixed Connected with the same top plate 5, the bottom of the top plate 5 is slidingly connected with a connecting pipe 6, one side of one of the connecting plates 2 is provided with a drive assembly for driving the connecting pipe 6 to move, and the drive assembly includes one of the connecting plates 2 away from The first motor 4 on one side of the connecting pipe 6, the output shaft of the first motor 4 extends to the inner side of the corresponding connecting plate 2 and is fixedly sleeved with a reciprocating screw rod 35 that is rotationally connected to the inner side of the other connecting plate 2, and the reciprocati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com