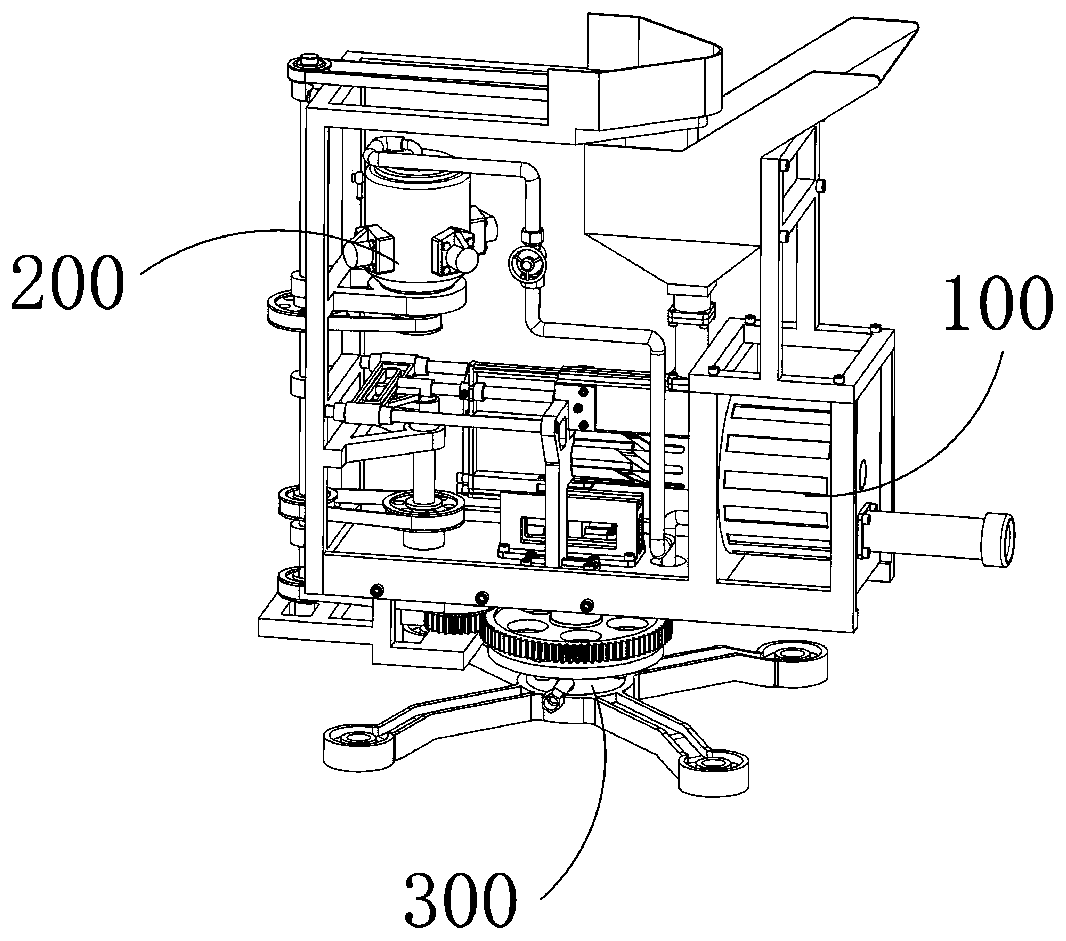

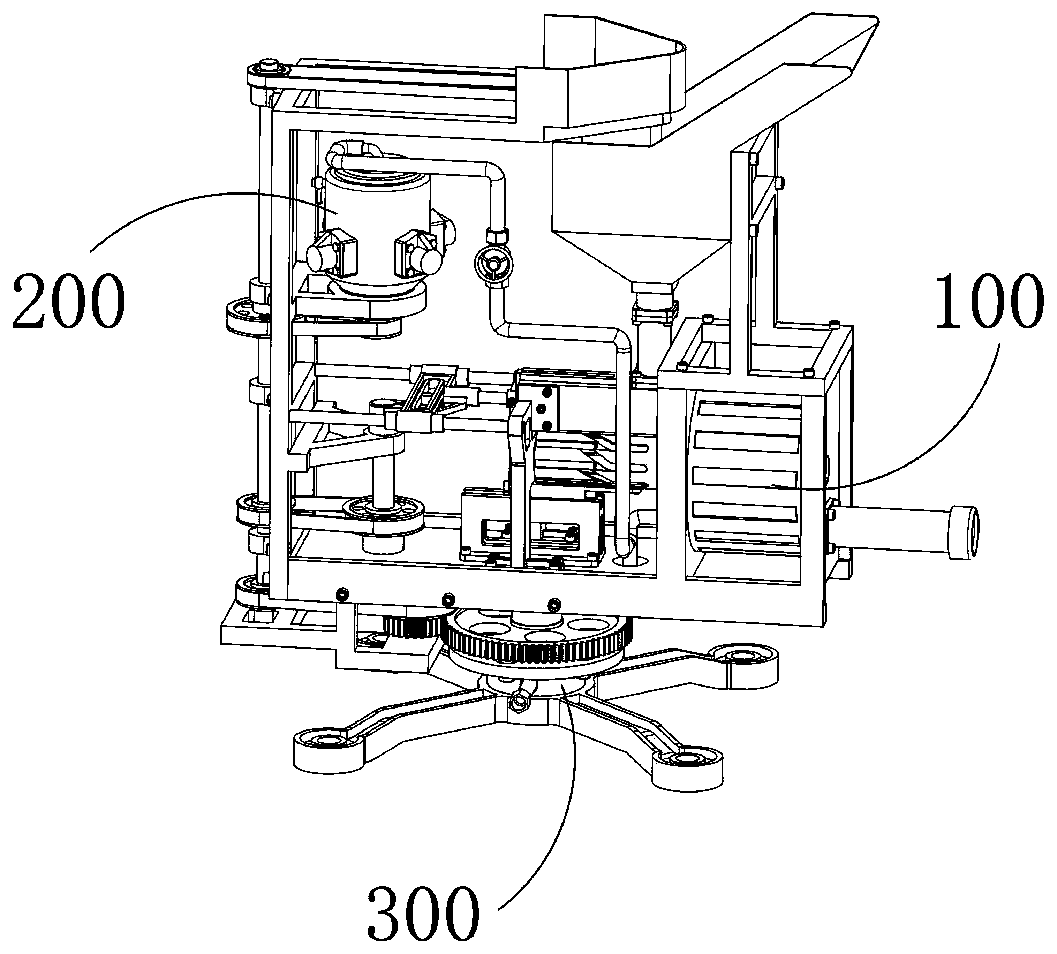

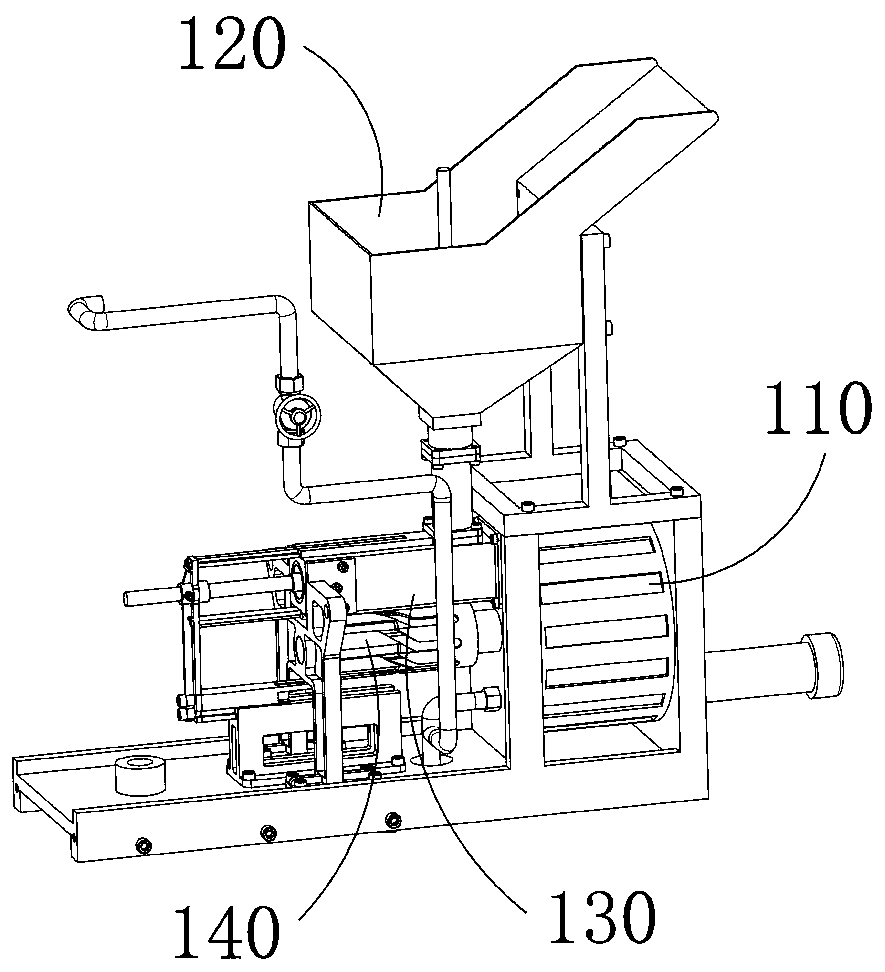

Rotary pneumatic-spraying type feedstuff feeding equipment

A feed and equipment technology, applied in the field of livestock breeding, can solve the problems of inhomogeneous distribution of feed, reduce labor intensity, large labor volume, etc., achieve better conveying effect, reduce labor intensity, and avoid damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention has the advantage of throwing and feeding the feed to the livestock breeding grounds in that the spray feeding device adopts the rotary pneumatic spraying method and throws and feeds the feed at a constant rate, so that the feed can be evenly spread around the feeding equipment from far to near. The distribution of feed increases the range of feeding and feeds evenly, which can effectively avoid unnecessary damage to livestock caused by looting feed. The entire throwing and feeding process is driven by equipment that can provide compressed gas such as a gas compressor. Just pour the feed into the feeding hopper, and the rest of the feeding process does not require manual operation, which greatly reduces the labor intensity. At the same time, the feed is conveyed through the auger in the feeding hopper, and the auger conveying effect is better and is not affected. Caking feed effects.

[0063] Feed feeding equipment that adopts the rotary pneumatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com