Low-temperature double-roller mirror image spiral extraction equipment and method

An extraction device and spiral technology, which is applied in the field of low-temperature double-rod mirror-image spiral extraction device, can solve the problems of high one-time investment and operation cost, large occupied space, and low extraction efficiency, so as to reduce equipment cost investment and occupation The effect of small space and improved extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

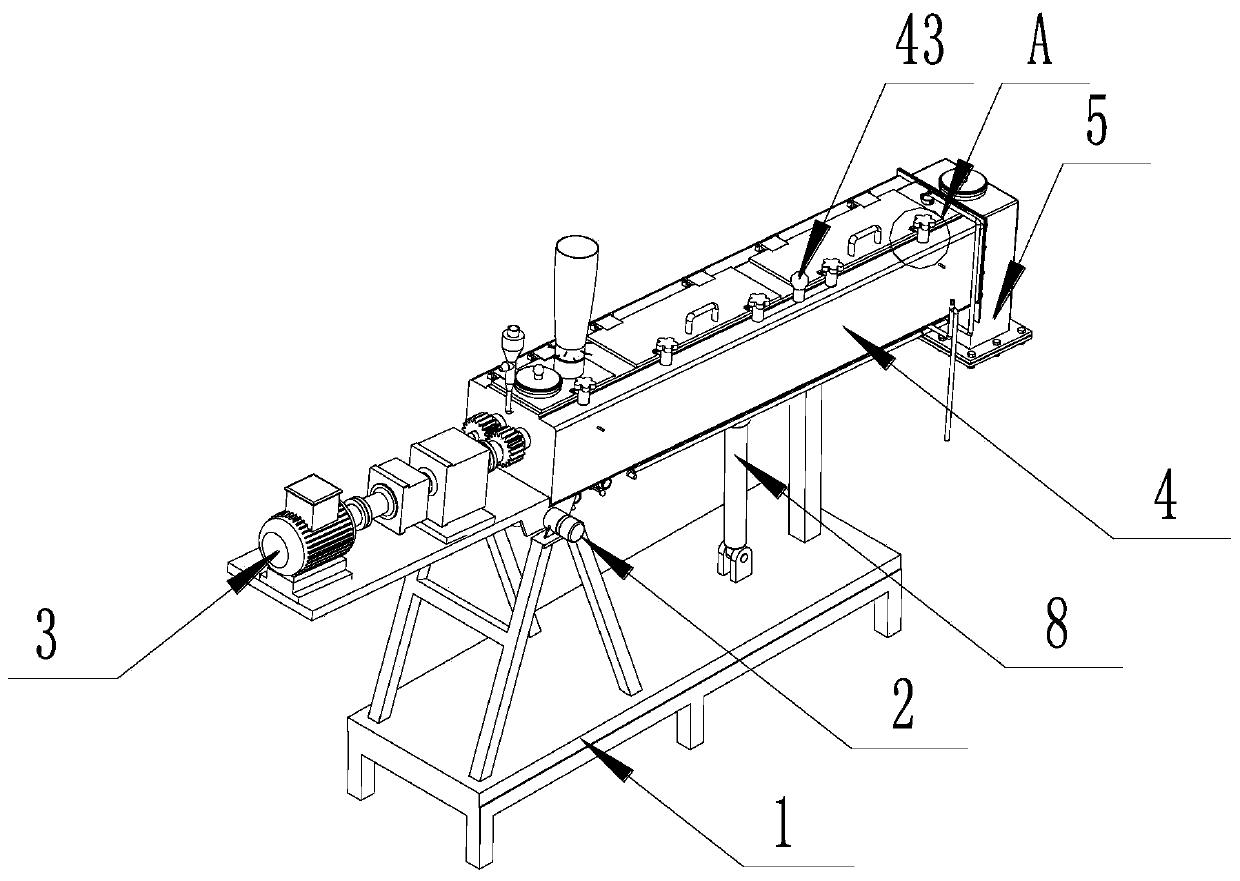

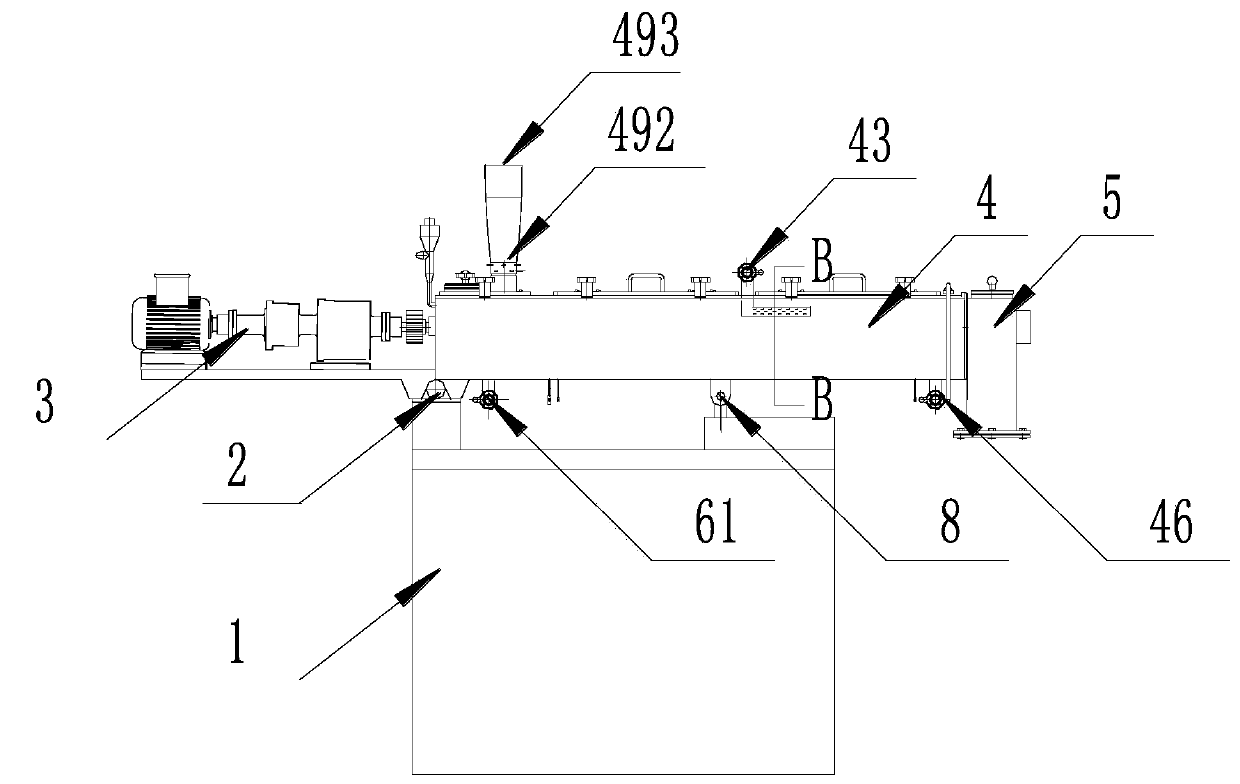

[0036] Example 1: See attached Figure 1-8 , A low-temperature double-stick mirror image spiral extraction device, including a support base 1, a hinge base 2, a transmission device 3, a main box body 4, a slag tapping box 5, a liquid tapping box 6, a spiral extraction device 7 and a lifting device 8.

[0037] Such as Figure 1-2 As shown, one end of the support base 1 is provided with a hinge base 2 and the other end is provided with a lifting device 7. The top of the hinge base 2 connects the transmission device 3 and the main box body 4; one end of the main box body 4 is provided with an outlet The other end of the liquid tank 6 is provided with a slag outlet box 5; the liquid outlet box 6 is located above the hinge seat 2.

[0038] The lifting device 8 is a hydraulic push rod. A feeder 492 is installed at the top of the main tank 4 near the outlet tank 6, and the top of the feeder 492 is a feed inlet 493.

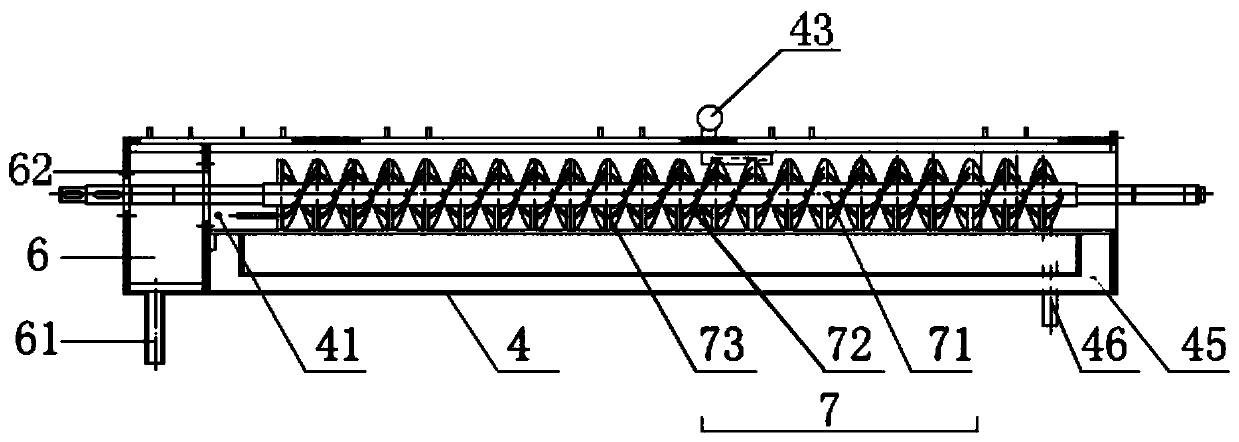

[0039] Such as Figure 3-4 As shown, the screw extraction device 7 inclu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap