Semi-solid die-casting forming die

A die-casting, semi-solid technology, applied in the field of molds, can solve the problems of inconvenient operation, low output efficiency, large space occupation, etc., and achieve the effect of convenient assembly, high processing efficiency, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

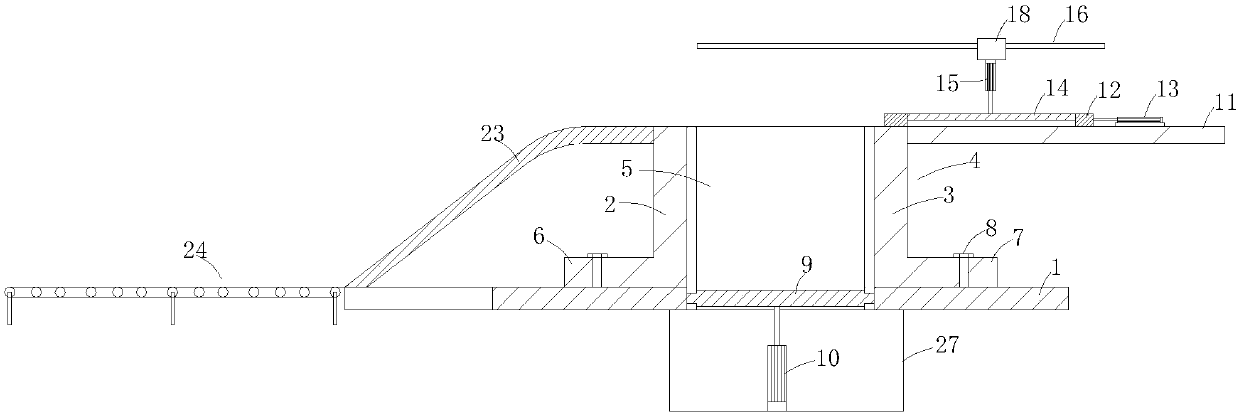

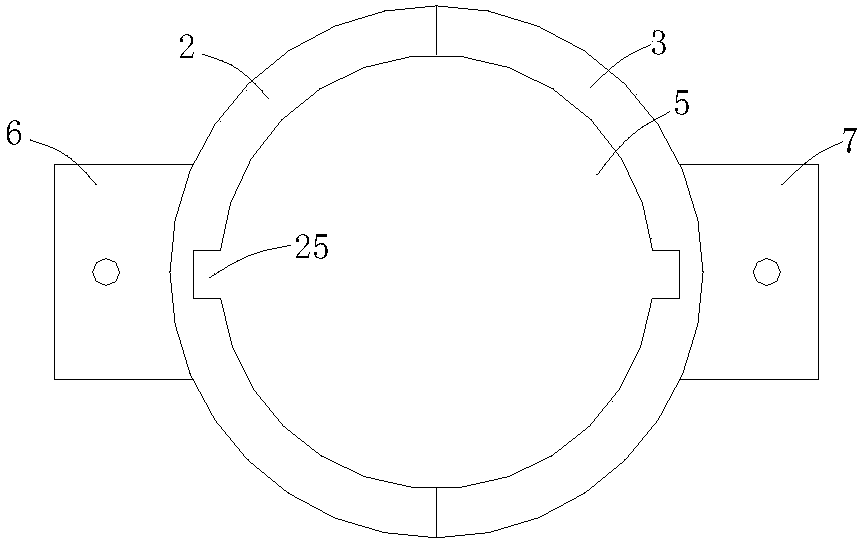

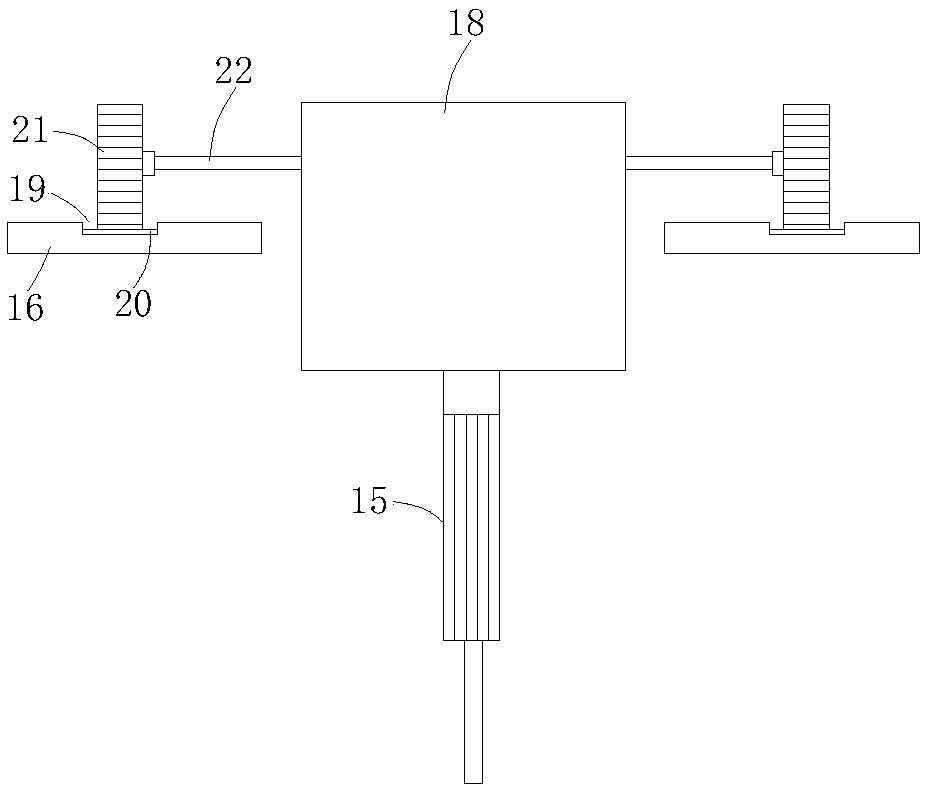

[0017] Such as Figure 1 to Figure 5 As shown, a semi-solid die-casting mold includes a base 1, a left mold cover 2 and a right mold cover 3 are arranged on the base 1, the cross sections of the left mold cover 2 and the right mold cover 3 are semicircular, and the left mold cover 2 Spliced with the right mold cover 3 to form a cylindrical mold cover 4, the inside of the mold cover 4 is a mold cavity 5, the bottom of the left mold cover 2 is connected to the left fixed plate 6, the bottom of the right mold cover 3 is connected to the right fixed plate 7, and the left fixed plate The plate 6 and the right fixing plate 7 are fixed on the base 1 by bolts 8, the two ends of the cavity 5 are open, the base 1 is provided with an opening connected to the port of the cavity 5, and the opening is provided with a hole extending into the cavity 5. The lower die-casting plate 9 is provided with a first cylinder 10 connected to the lower die-casting plate 9 under the base 1;

[0018] Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap