Tool and device capable of pre-fixing four-way valve and D joint tube

A four-way valve and pre-fixing technology, which is applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve the problems of D pipe falling off, different insertion depths, and low production efficiency, and achieve stable control of verticality and uniform fit clearance , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be clearly and completely described below. All other implementations obtained below fall within the protection scope of the present invention.

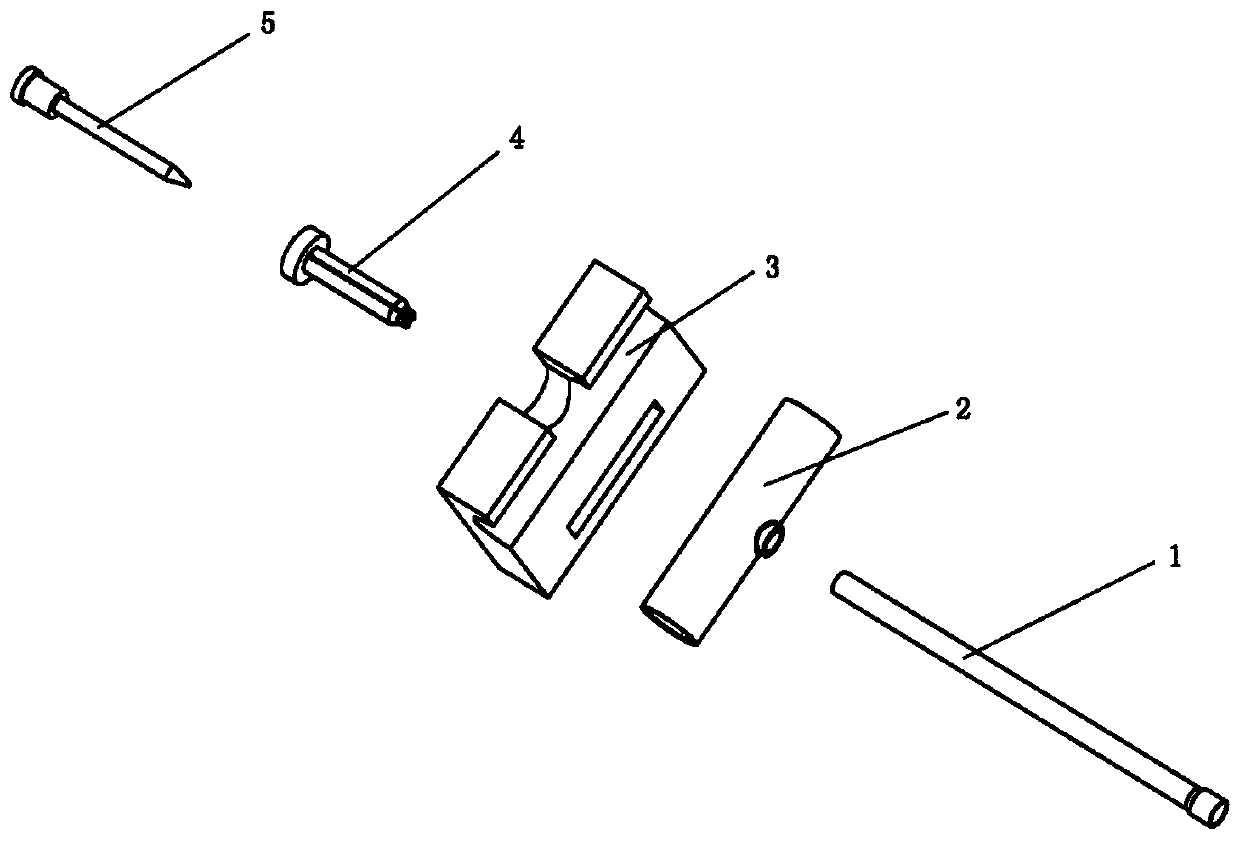

[0037] Such as figure 1 As shown, the tool for pre-fixing the four-way valve and the D-joint provided in this embodiment includes: a tube expansion head 4 , a tube expansion needle 5 and a positioning seat 3 .

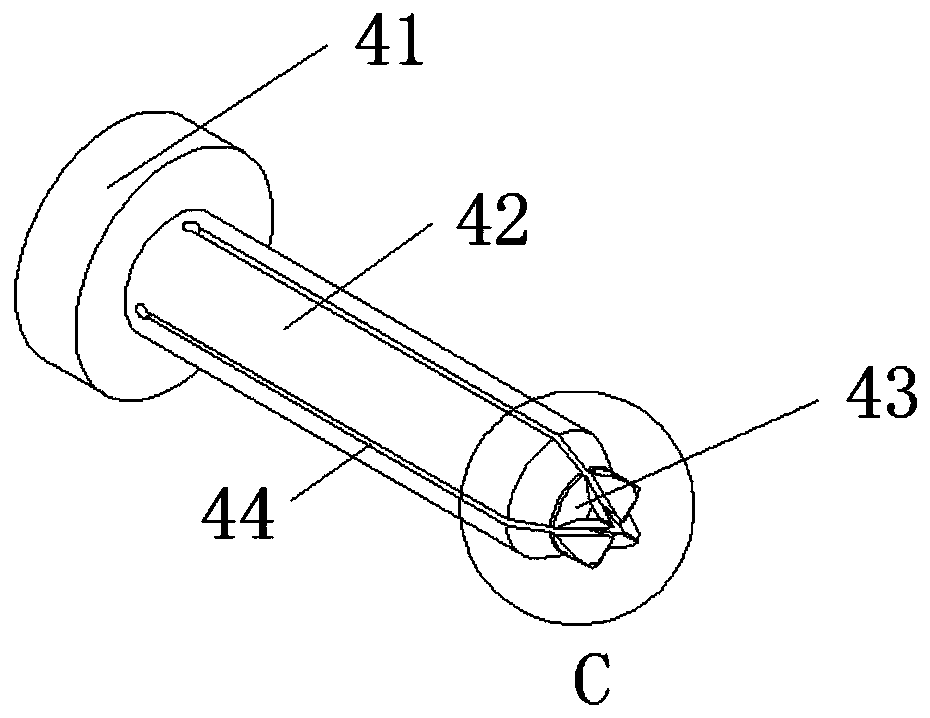

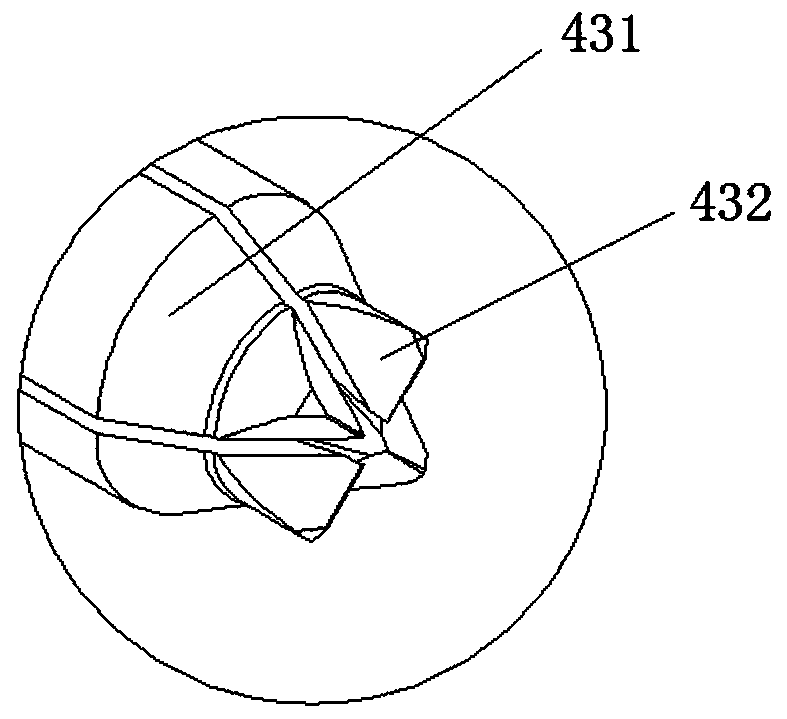

[0038] The expander head 4 is used to expand the inner diameter and outer diameter of the D-connector 1 at the same time. Such as Figure 2-4 As shown, the expander head 4 includes a base part 41 , a main body part 42 and an expander part 43 , the base part 41 , the main body part 42 and the expander part 43 are sequentially connected and processed by an integral molding process to form the expander head 4 . The inside of the expander head 4 is provided with a cavity 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com