Embedded starting and rotating device of small turbine engine and aircraft with embedded starting and rotating device

A turbine engine and embedded technology, which is applied in the direction of gas turbine devices, gas turbine power devices, engine components, etc., can solve the problems of reducing the number of starts, difficulty in parts replacement and maintenance, and increasing the load of the main shaft, so as to improve efficiency and improve Ease of maintenance and reduction of power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

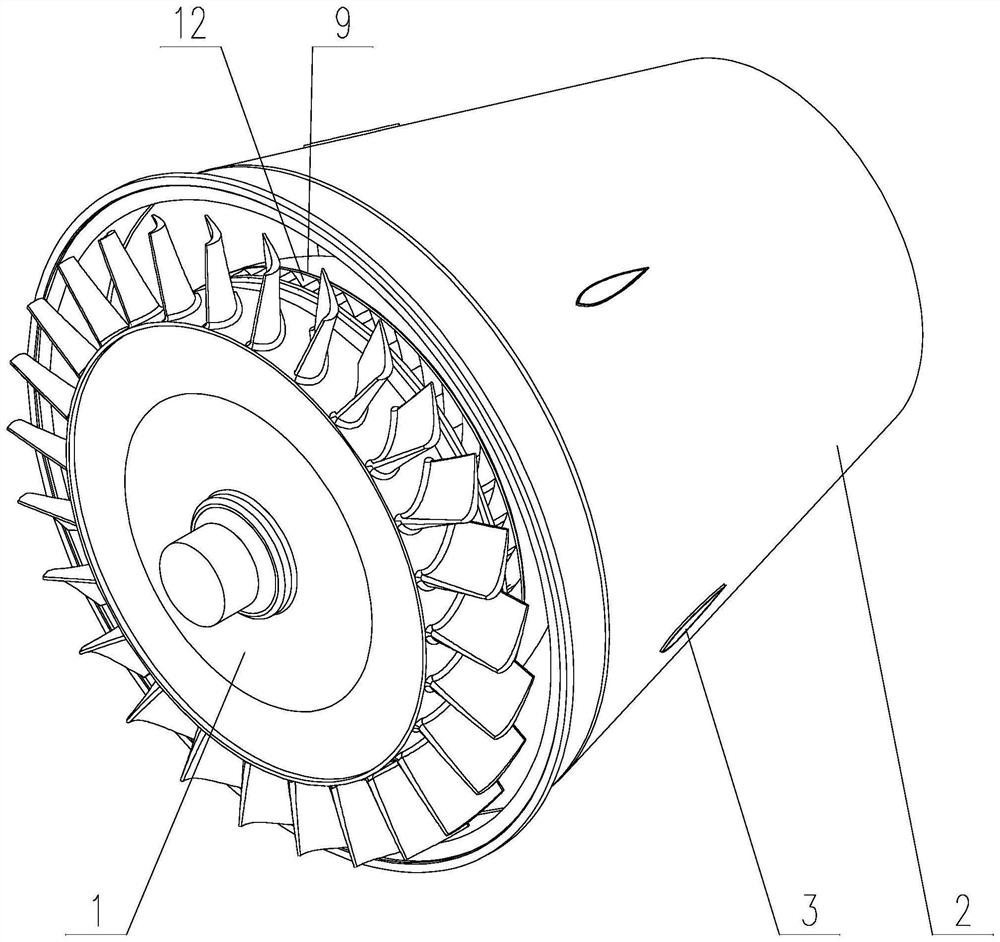

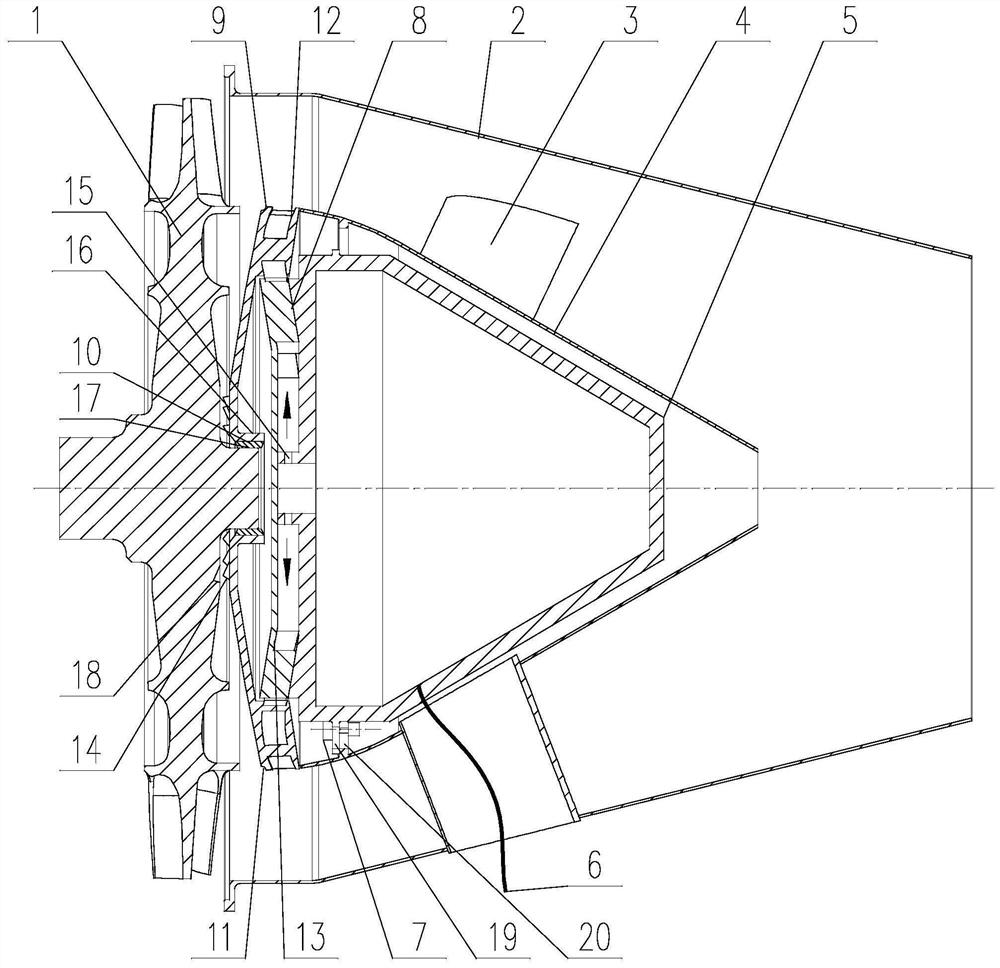

[0052] Such as Figures 1 to 17 As shown, the embedded starting and rotating device of the small turbine engine of the present invention includes a gas blowing turbine assembly fixed on the tail nozzle assembly for starting the engine turbine 1 to rotate, and the gas blowing turbine assembly includes a gas blowing turbine assembly fixed on The gas generator 5 on the tail nozzle assembly and the guider 8 and the blowing turbine 9 that are all located between the gas generator 5 and the engine turbine 1, the guider 8 is provided with the inner side and the gas outlet of the gas generator 5 15 communicated with the inner gas channel 13, the edge of the blowing turbine 9 is provided with an outer gas channel 12 whose inner side communicates with the outer side of the inner gas channel 13;

[0053] After the high-temperature gas generated by the gas generator 5 passes through the deflection of the inner gas passage 13 and the outer gas passage 12, it pushes the blowing turbine 9 to...

Embodiment 2

[0062] About the matching position between the blowing turbine 9 and the engine turbine 1 in embodiment 1, the specific implementation is as follows:

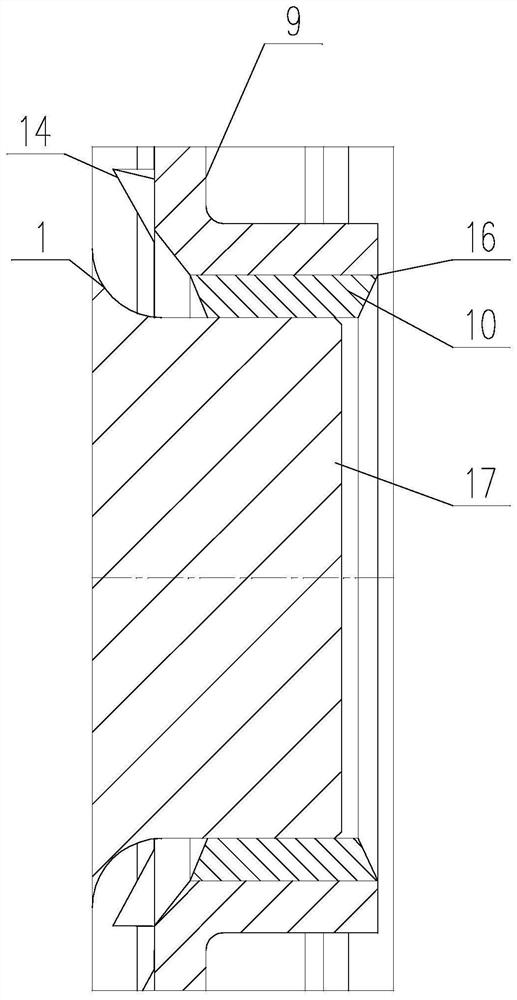

[0063] Such as figure 2 with image 3 As shown, the wear coating 10 is coated on the inner ring 16 of the blowing turbine 9 , and the thickness of the wearing coating 10 is greater than the radial gap between the blowing turbine 9 and the guide 8 .

[0064] The inner ring 16 of the blowing turbine 9 is coated with an abrasive coating 10, which forms a clearance fit with the shaft end cylinder 17 of the engine turbine 1, and can translate the blowing turbine 9 axially on the shaft end cylinder 17 of the engine turbine 1, Ensure that the meshing and disengaging axial movement of the toothed discs is not stuck.

[0065] The thickness of the wear coating 10 is greater than the radial gap between the blowing turbine 9 and the guide 8, so as to ensure that after the engine is started successfully, when the wear coating is consumed...

Embodiment 3

[0080] The implementation of the exhaust nozzle assembly is as follows:

[0081] Such as figure 2 As shown, the tail nozzle assembly includes the tail nozzle inner ring 4 sleeved on the gas generator 5, the tail nozzle outer ring 2 sleeved on the tail nozzle inner ring 4, and the tail nozzle inner ring 4 and the tail nozzle The nozzle outer ring 2 is fixedly connected to the tail nozzle support plate 3, and the gas generator 5 is connected to the tail nozzle inner ring 4 through a flange assembly, and the flange assembly is provided with a port for air flow. The guide 8 is installed on the large-diameter end of the gas generator 5 to jointly form a gas guide channel. Specifically, one channel wall of the inner gas channel 13 is formed by the end face of the gas generator 5, and the remaining channel walls are formed by the guide 8, thereby reducing Axial dimensions and weight of the small device.

[0082] Preferably, the tail nozzle support plate 3 is hollow, and the ignition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com