Lower vehicle-body structure

A car body and structure technology, which is applied in the direction of superstructure, superstructure sub-assembly, and connection between superstructure sub-assemblies, can solve the problem that the rigidity of the car body is not enough to suppress the decline, and achieve a firm fixed structure, The effect of improving the rigidity of the vehicle body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

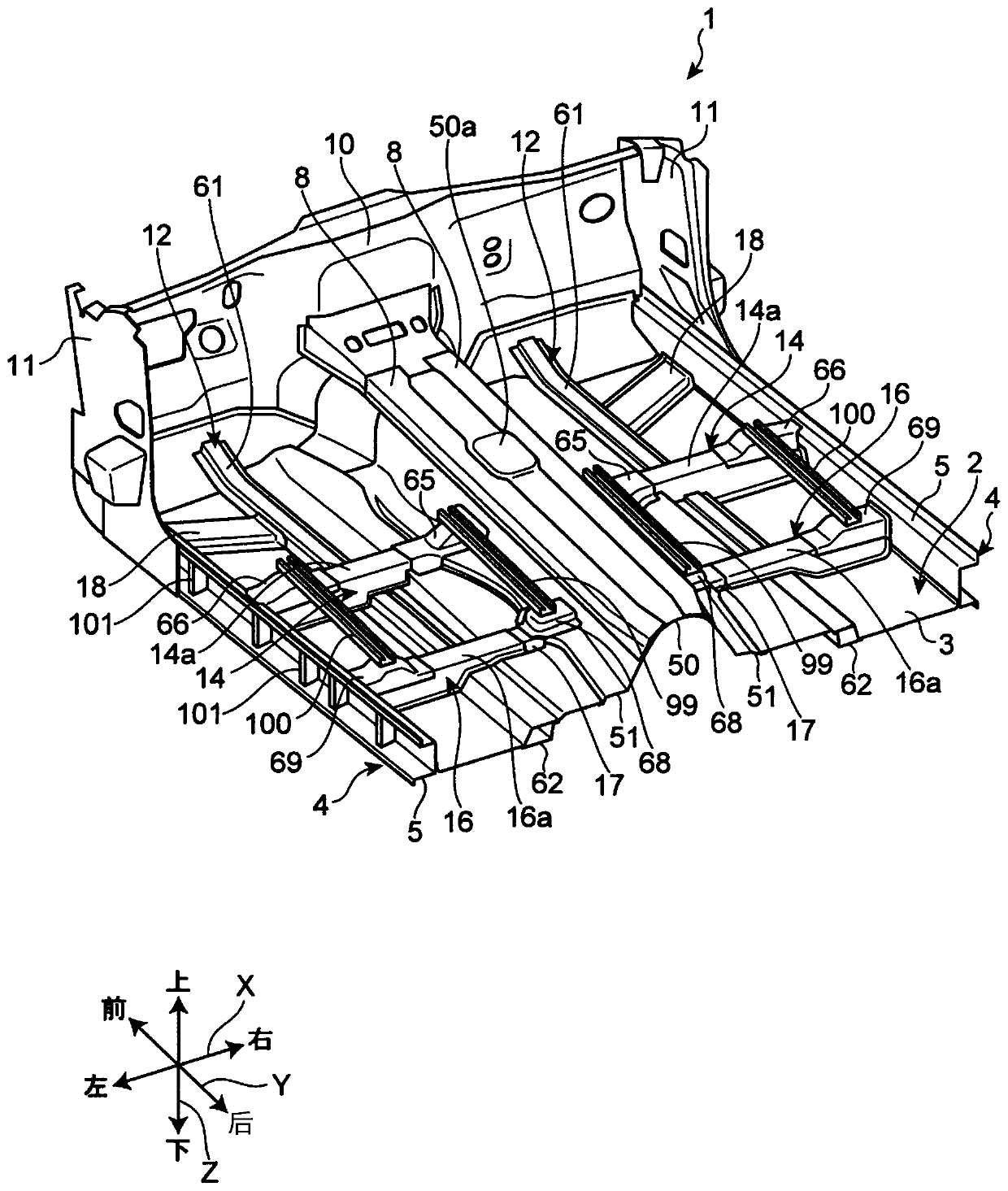

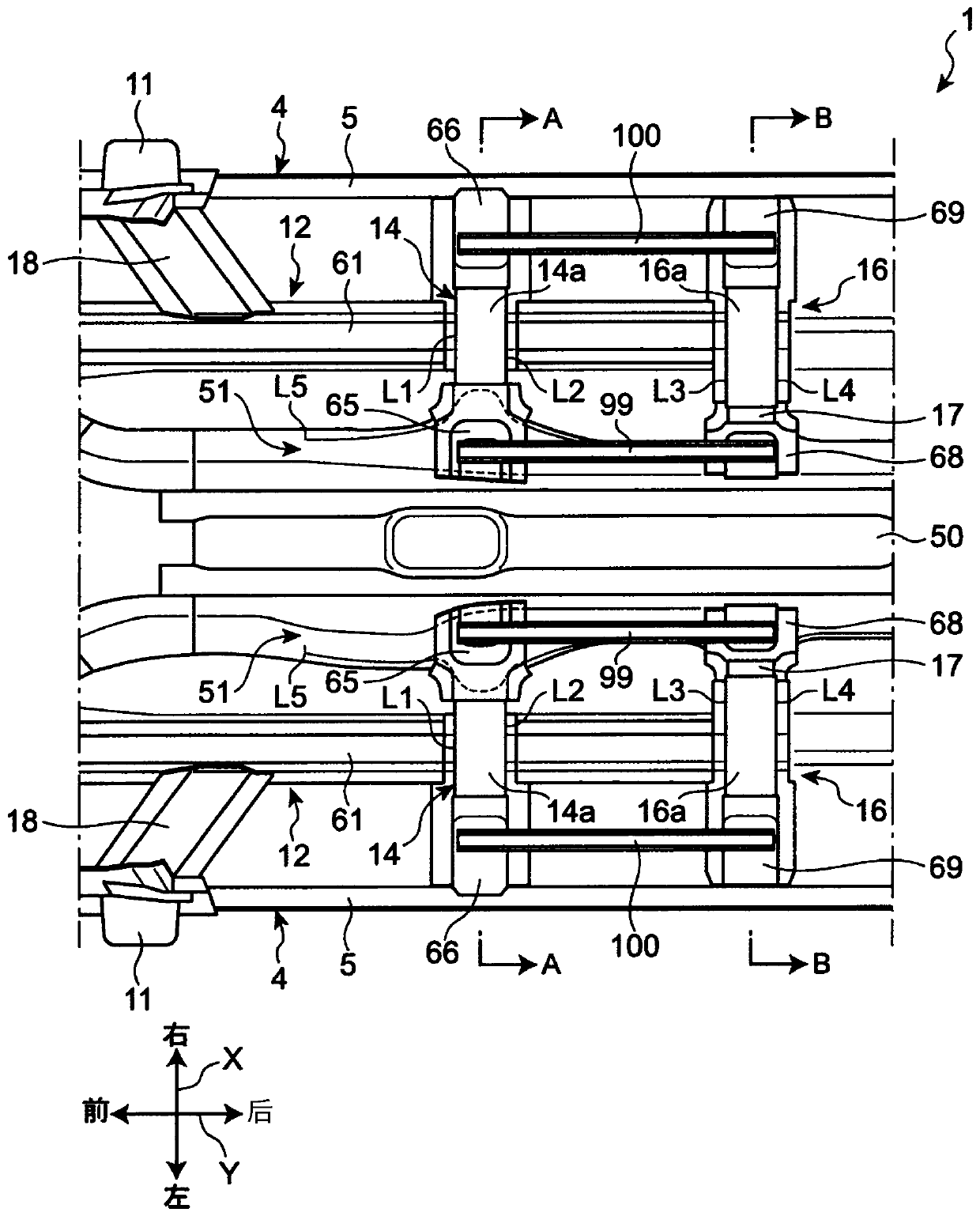

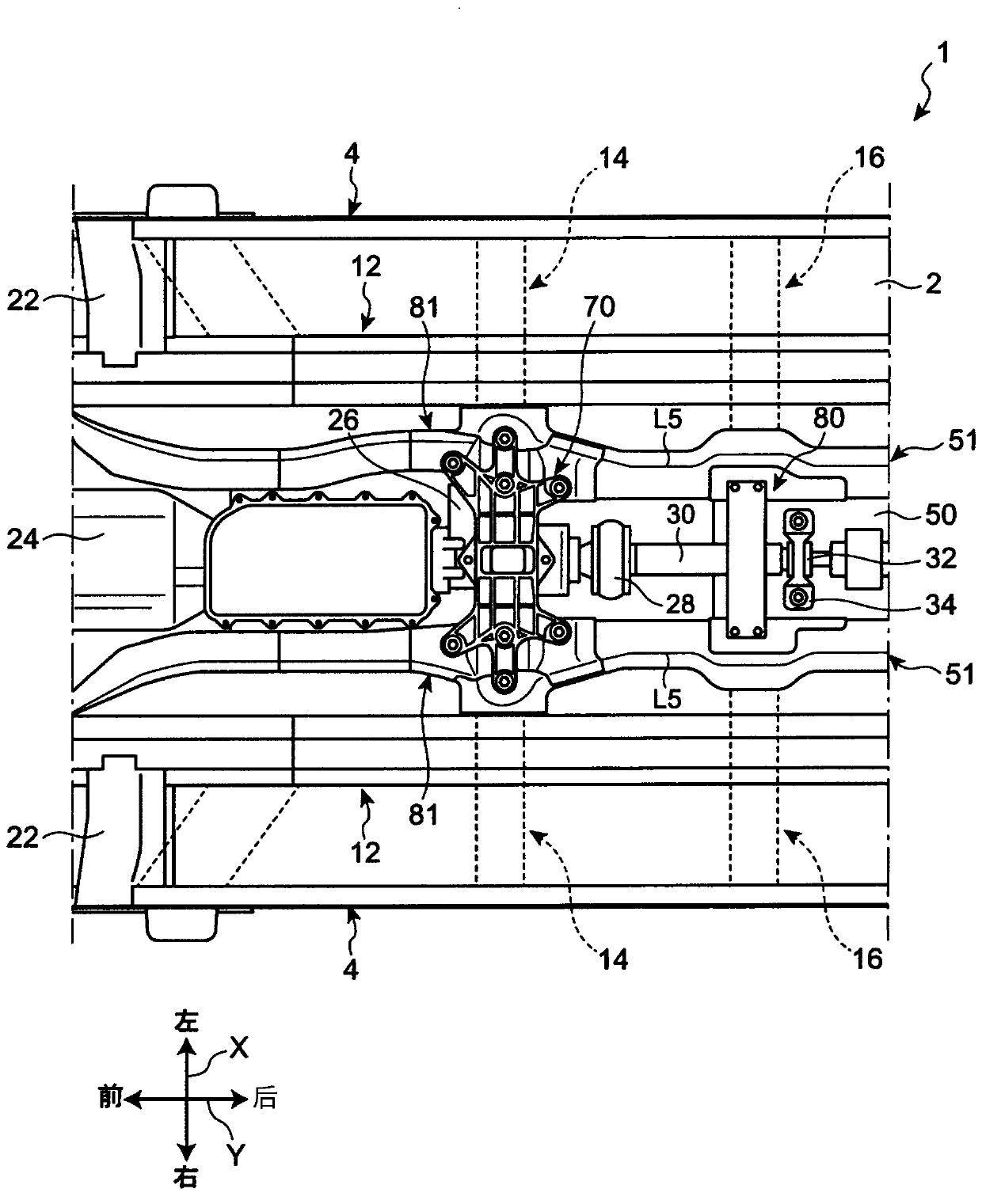

[0040] A lower vehicle body structure according to an embodiment of the present invention will be described below with reference to the drawings.

[0041] [overall composition]

[0042] figure 1 It is a perspective view showing the lower vehicle body structure of this embodiment. figure 2 It is a plan view showing the structure of the lower vehicle body. image 3 It is a bottom view showing the structure of the lower body. In the following description, the vehicle width direction, the vehicle front-rear direction, and the vehicle vertical direction of the automobile 1 provided with the lower body structure of the present embodiment may be referred to as X direction, Y direction, and Z direction, respectively.

[0043] refer to figure 1 The automobile 1 provided with the lower body structure of this embodiment includes: a vehicle body floor 2 constituting the floor of the interior space of the vehicle compartment; a pair of sides extending in the Y direction along both sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com