A kind of rubber toughened polypropylene compound and its application

A technology of rubber toughening and polypropylene, which is applied in the field of polymer materials and their molding processing, can solve the problems of poor dispersion effect, achieve the effects of reducing the average particle size, promoting dispersion, and excellent impact performance at abnormal temperature and low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12 and comparative example 1-7

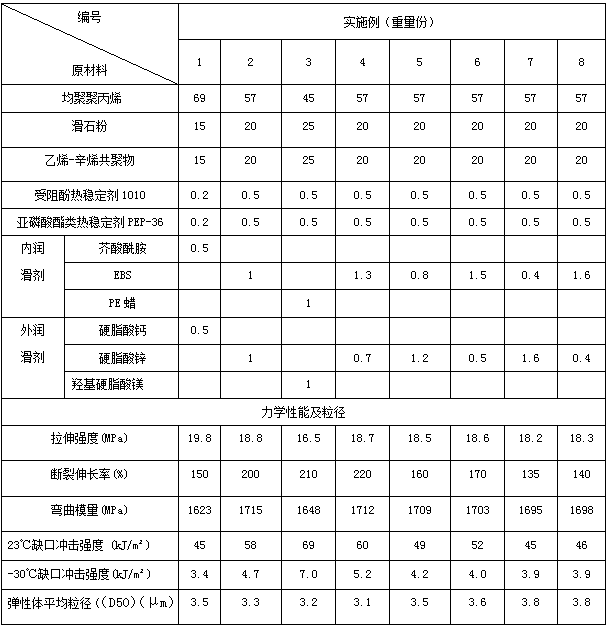

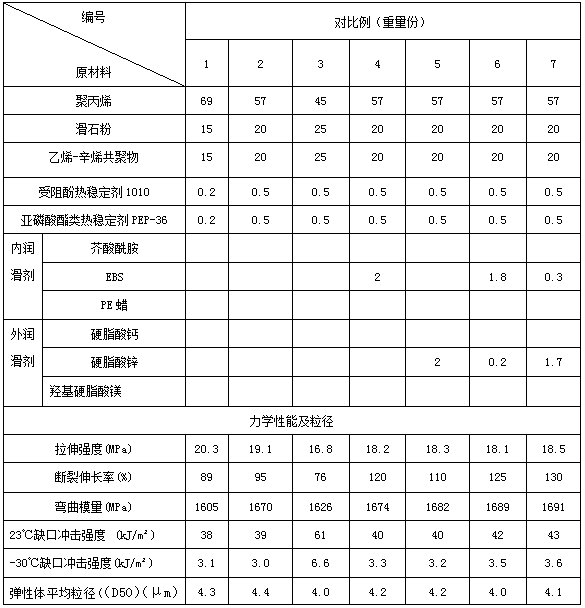

[0039] Weigh the components according to the parts by weight shown in Table 1, and melt, mix and disperse polypropylene, elastomer, talcum powder, heat stabilizer and lubricant in a twin-screw extruder with a length-to-diameter ratio of 40:1. The temperature was maintained at the melting temperature of 180-210°C, extruded and granulated, and rubber-toughened polypropylene composites were finally obtained. Corresponding test samples were made according to the standards, and their mechanical properties were measured. The specific values are listed in Table 1.

[0040] Table 1 Composition and properties of rubber-toughened polypropylene compounds

[0041]

[0042] Continued Table 1

[0043]

[0044] Continuation of Table 1:

[0045]

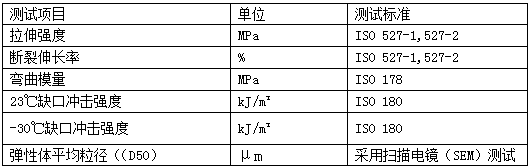

[0046] Each performance test is carried out according to the standards in Table 3 below:

[0047] table 3:

[0048]

[0049] It can be seen from the test results of various examples and comparative examples that the present inventio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com