Rope releasing device of unmanned aerial vehicle

The technology of a machine rope releaser and a rope reel is applied in the field of fire rescue equipment, which can solve the problems of the unmanned aerial vehicle rope releaser being difficult to pull the rope to the ground, and achieve the effect of safety in use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

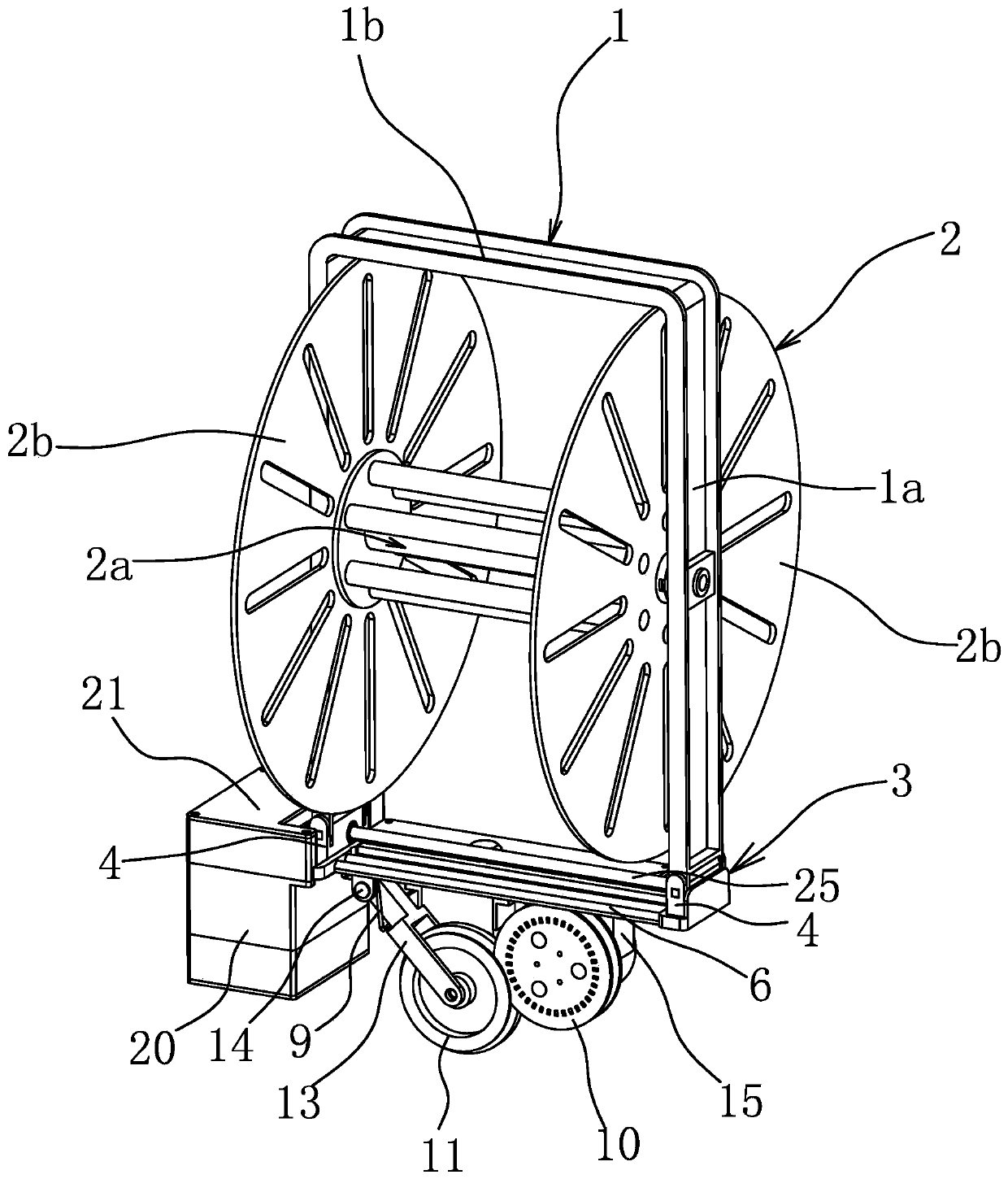

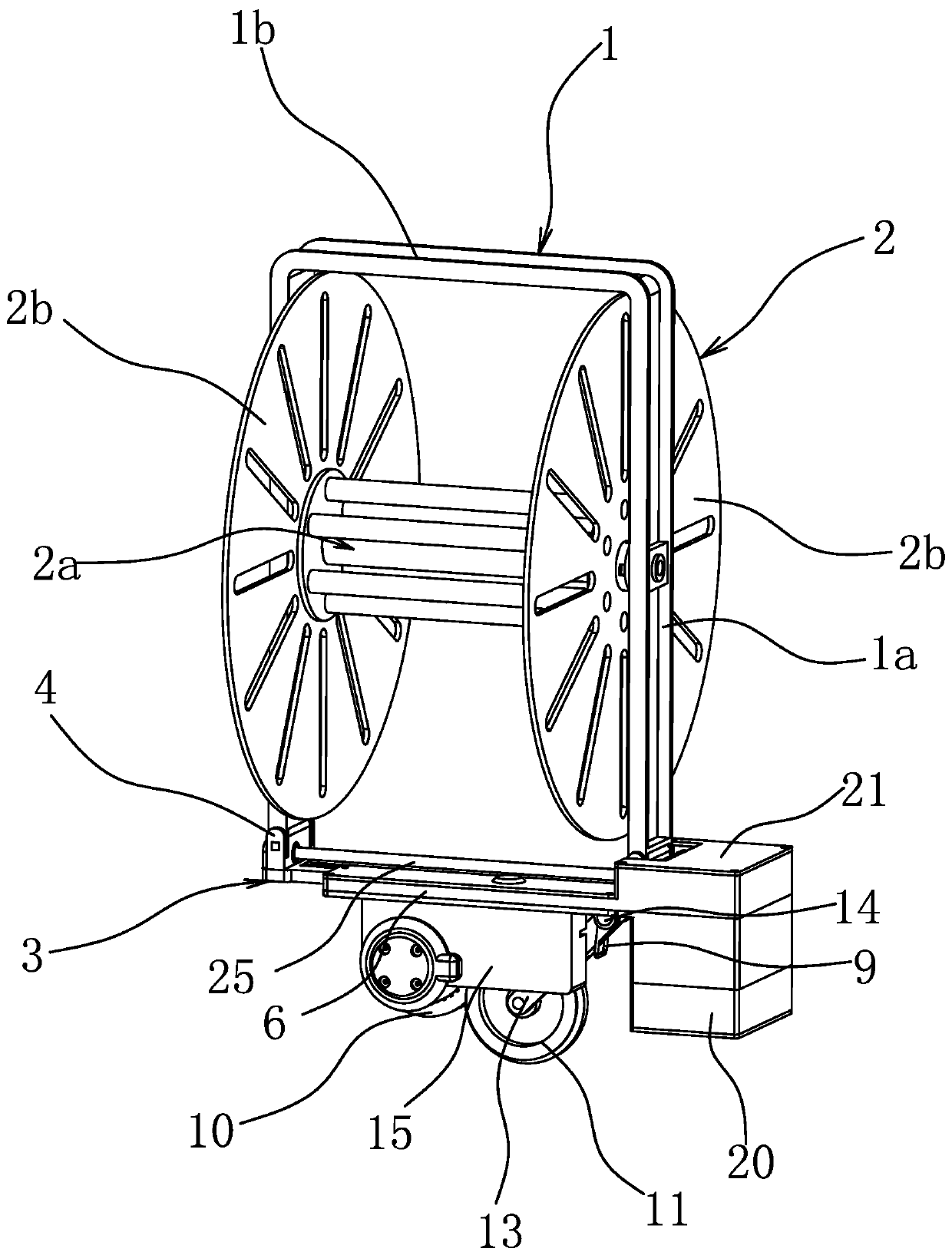

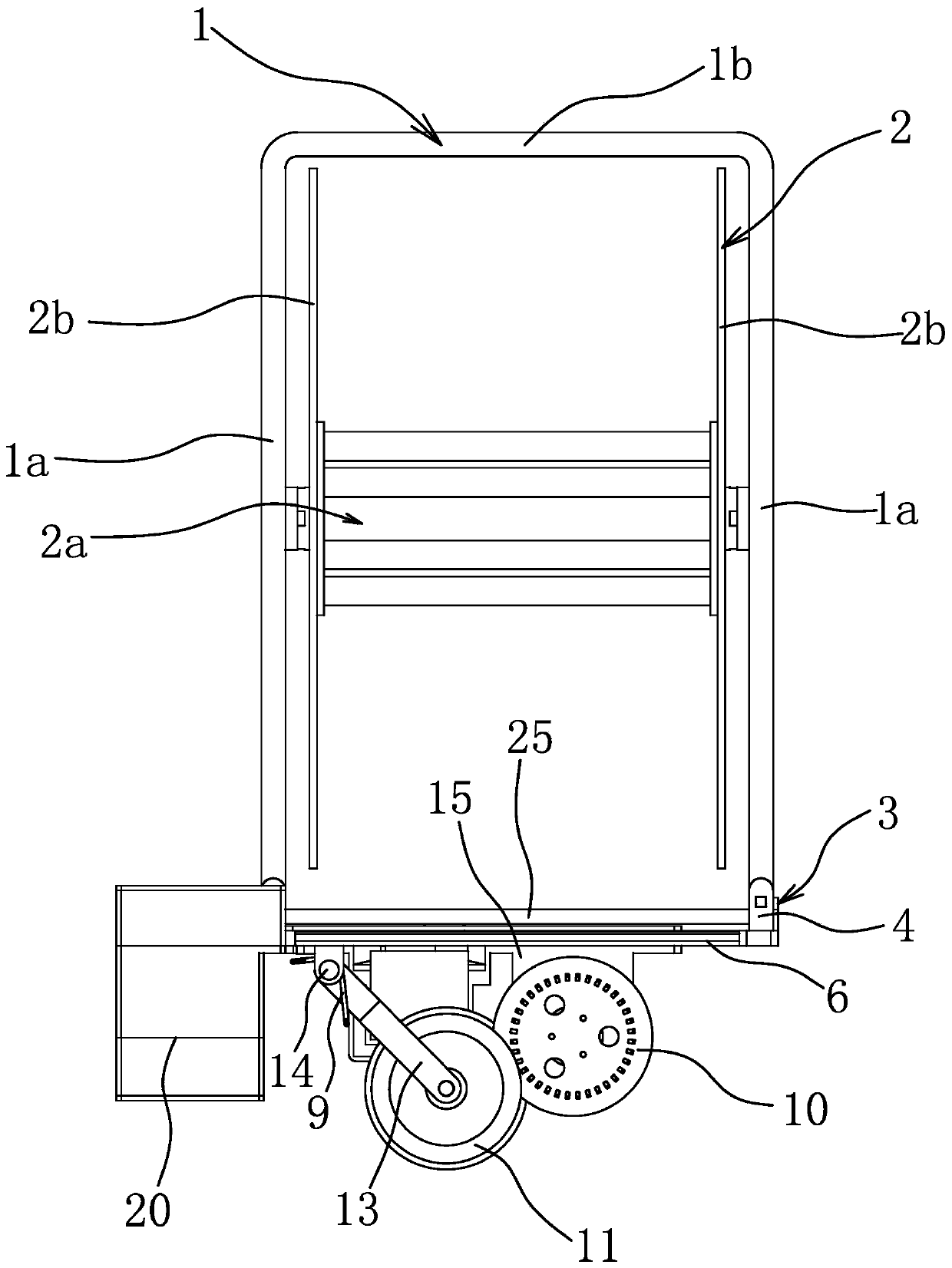

[0045] Such as figure 1 , figure 2 with image 3 As shown, the UAV rope release device includes a rope reel support 1, a throwing frame 3 and a rope reel 2 for winding the traction rope. The rope reel 2 includes a reel 2a, and the two ends of the reel 2a are respectively connected with a 2a is perpendicular to the rope retaining plate 2b. The throwing frame 3 is connected to the bottom of the rope reel support 1 through connecting parts. The rope reel support 1 is U-shaped and includes a top beam 1b and two opposite side support beams 1a, and the rope reel 2 is rotatably connected to the two side support beams. Between 1a, the top beam 1b is used to connect with the UAV, and the throwing frame 3 is also provided with a rope release mechanism for connecting with the traction rope and controlling the speed of the traction rope.

[0046] Specifically, such as image 3 with Figure 4As shown, the bottom surface of the throwing frame 3 is fixedly connected with a motor cover ...

Embodiment 2

[0059] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that, as Figure 17 As shown, the connecting parts include a grasping manipulator 26 arranged at the bottom of the rope reel support 1, and the throwing frame 3 has a grasping part 31 clamped by the grasping manipulator 26, and the driving member 7 can control 26 grabbing manipulators. open or closed.

Embodiment 3

[0061] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that, as Figure 18 As shown, the throwing frame 3 is connected to the side of the rope reel support 1 through a connecting part. Specifically, the two side support beams 1a of the rope reel support 1 are respectively connected to an extension frame 1c, and a locking hole is provided on the extension frame 1c. 1a2, the connecting part includes a locking piece 5 arranged on the throwing frame 3, the locking piece 5 extends into the locking hole 1a2, when the driving piece 7 drives the gear to rotate, it drives the locking piece 5 to move, so that the locking piece 5 escapes from the locking hole 1a2 , and then realize that the throwing frame 3 breaks away from the rope reel support 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com